(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

--

--

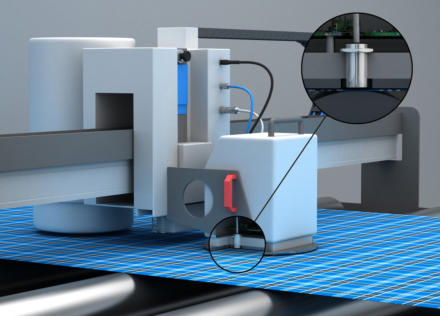

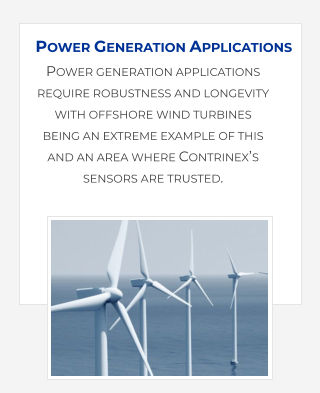

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

CONTINUOUS PRODUCTION AS IN-PROCESS MEASUREMENT IS

HIGHLY ACCURATE WITH HIGH SAMPLING RATE

DEFECTS IDENTIFIED IN REAL TIME MINIMISES REJECT COSTS

NO RESTRICTIONS ON MOUNTING POSITION AS SENSORS ARE

VIBRATION-RESISTANT AND TEMPERATURE-STABLE

COMPATIBILITY WITH EXISTING IN-HOUSE SYSTEMS 0 TO 10V

LONG SENSING DISTANCE MINIMISES RISK OF MECHANICAL

DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

EXCEPTIONAL DETECTION ACCURACY, EXCELLENT

REPEATABILITY AND RESOLUTION IN THE MICRON RANGE (µM)

SAMPLING RATE OF 250HZ

CONDIST® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 10 MM

RUGGED, VIBRATION-RESISTANT WITH METAL HOUSINGS

INDUSTRY-STANDARD 0 TO 10V ANALOGUE OUTPUTS

A manufacturer of industrial timing belts trusts Contrinex’s

analogue inductive sensors to measure the position of steel

reinforcing bands during continuous production.

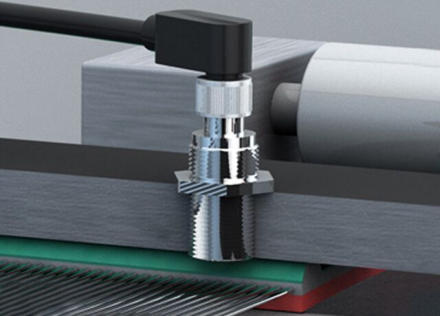

Two long-range, high-resolution sensors, mounted above the

extruded belt profile, provide real-time positional data. The

customer’s process-control system monitors the sensor’s

analogue voltage outputs, alerting the operator and halting

production if the values are outside allowable limits.

CUSTOMER APPLICATION

To enhance the strength of industrial timing belts, steel

reinforcing wires are bonded into the belt carcass as part of a

continuous extrusion process. The distance between the

reinforcing wires and the belt teeth is a critical parameter,

influencing the accuracy of the belt’s fit and other operating

characteristics, including service life.

Engineers can check product quality at intervals by cutting

samples of extruded belts and taking optical measurements,

but this process is slow and only detects faults some time after

production is complete, leading to high reject costs.

The customer requires a real-time system with sensors that

reliable and accurately measure the position of the steel

reinforcement.

CUSTOMER SOLUTION

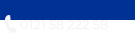

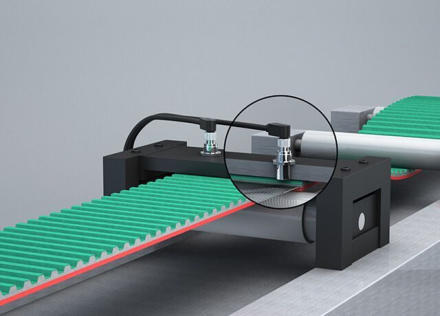

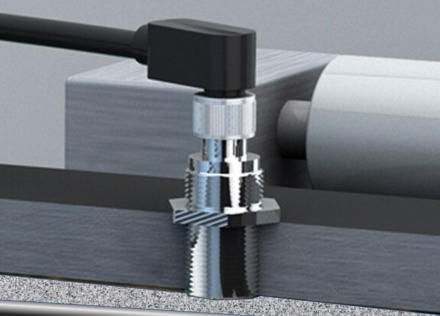

Contrinex M18-size analogue inductive sensors are ideal for this

application providing an analogue voltage output with a

sampling rate of at least 100Hz. The physical characteristics of

the belt dictate a sensing distance of up to 10 mm with micron

(µm) measurement accuracy. Contrinex’s patented Condist®

technology provides a highly stable sensing performance at

operating distances of ≤10 mm with exceptional detection

accuracy, excellent repeatability and resolution in the micron

range.

The sensors sample at 250Hz, enabling accurate measurement

of the position of the steel reinforcement in the fast moving

belt profile, and provide continuous, non-linearised 0 to 10V

analogue output signals. They are resistant to vibration and

variations in ambient temperature, allowing their positioning

immediately after the extrusion press in close proximity to the

moving belt.

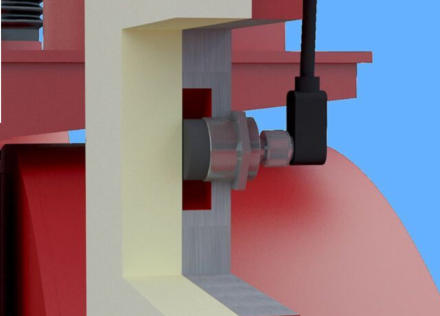

Two sensors, set flush into a non-metallic plate, are mounted

directly above the surface of the belt as it runs over a guide

roller, giving a stable reference position. The lightly tensioned

belt clears the sensing face of the devices by a few tenths of a

millimetre. Connection to the customer’s control system is via

a flexible cable with an easily detachable M12 connector.

The introduction of Contrinex analogue inductive sensors

provide small, high-accuracy, ultra-reliable sensors with a low

total cost of ownership.

Rather than needing to destructively test belts to inspect the

position of the steel reinforcement and risking high reject

costs because of the infrequent nature of the sampling, the

production process is now continuously monitored.

CUSTOMER VALUES

HIGH-SPEED CHECKING OF DIFFERENT CAN TYPES

SINGLE SOLUTION TO CHECK DIFFERENT CAN TYPES

SIMPLE INSTALLATION - DIRECT INTERFACE TO CONTROLLER

(0 – 10 VDC OR 4 – 20 MA)

LONG SERVICE LIFE, HIGHLY RELIABLE, COST-EFFECTIVE

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG SENSING RANGE OF 40MM

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT, RESOLUTION

IN µM RANGE

EXCELLENT TEMPERATURE STABILITY & VERY GOOD

REPEATING ACCURACY

SEVERAL SWITCH POINTS WITH A SINGLE DEVICE

LONG SENSING DISTANCE COMPARED TO COMPETITORS

CUSTOMER SOLUTION

Analogue inductive sensors from Contrinex’s 509 Series are

ideal for this application because their Condist® oscillator

technology ensures excellent environmental stability,

especially to temperature. This is key in providing sensing

distances up to 3 times the standard (in this case 40 mm from

the M30 sized sensor).

This extra sensing distance ability enables them to obtain a

good signal not only through multiple layers of cardboard but

also from different conductive metals at varying distances,

depending on the can type.

The customer mounted the M30 sized inductive analogue

sensors which yield the greatest sensing distance above and

below the passing lanes of cans so that the double layer of

cans in each carton can be checked through the cardboard

walls of the box.

The continuous analogue current or voltage output from

these sensors is connected directly to a PLC with a high-speed

analogue input card. Resolution is in the µm range and repeat

accuracy is very good. The solution excels because it is durable,

adaptable, reliable and simple to install.

.

To ensure that sealed cardboard cartons have the required

number of tinned food cans inside them, a packaging

company trusts Contrinex’s analogue inductive sensors. Using

an analogue sensor enables this final pre-shipment quality

check to process different sizes of can as well as manage with

different material grades of can.

CUSTOMER APPLICATION

Canned products and their labels are protected during

delivery by being tightly packed into sturdy sealed cardboard

boxes. This poses a challenge to food packaging companies

because retailers, particularly supermarkets require absolute

accuracy in the contents of the carton, but at final inspection,

the carton is already sealed and so the contents can not be

visually inspected.

Therefore to eliminate the risk that product faults that may

have occurred during upstream processes are shipped out to

the customers, the packing company needed a way to verify

what tins are inside the sealed box. Because the packaging

line handles a variety of cans of different sizes and materials, a

conventional on-off switching inductive proximity sensor could

not be used.

An additional challenge is that the sensor needs to be part of a

verification process integrated into a fast-moving automated

packaging and pre-shipment line, accepting or rejecting each

carton instantly.

.

CUSTOMER VALUES

HIGH-SPEED CHECKING OF DIFFERENT CAN TYPES

SINGLE SOLUTION TO CHECK DIFFERENT CAN TYPES

SIMPLE INSTALLATION - DIRECT INTERFACE TO CONTROLLER

(0 – 10 VDC OR 4 – 20 MA)

LONG SERVICE LIFE, HIGHLY RELIABLE, COST-EFFECTIVE

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG SENSING RANGE OF 40MM

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT, RESOLUTION

IN µM RANGE

EXCELLENT TEMPERATURE STABILITY & VERY GOOD

REPEATING ACCURACY

SEVERAL SWITCH POINTS WITH A SINGLE DEVICE

LONG SENSING DISTANCE COMPARED TO COMPETITORS

CUSTOMER SOLUTION

Contrinex analogue inductive sensors from their Extra

Distance 509 Series family are perfect for the position and

distance measurement requirements of this application. The

sensors provide an analogue value for the entire motion

sequence of the x-ray inspection. Their excellent resolution in

µm range is particularly suitable for measuring gaps and

angles, detecting motion and controlling travel smoothly.

The sensors are positioned to measure both the pipe carriage

position, which represents the system’s zero-point and is

therefore critical for correct operation and the distance

between the x-ray source and the pipe surface which is critical

to x-ray result quality.

The analogue sensors output a continuous voltage or current

analogue signal which reflects the gap between the damping

element and the sensing surface.

With Contrinex’s patent-protected Condist technology, these

high-performance analogue sensors provide a sensing range

that is more than twice the distance offered by competitors.

The M30 versions used in this application offer a sensing range

of 0 to 40 mm and so they can provide the flexibility required

for testing the numerous pipe diameters being manufactured.

The solution excels because it is durable, adaptable, reliable

and was also fast and simple to install.

.

The integrity of weld seams in pipes used to transport oil or

gas across land or sea is ensured using x-ray testing. The x-ray

test systems used for this require precision control of the

distance between the x-ray source and the surface of the pipe

because this is critical for the quality of the imaging data.

CUSTOMER APPLICATION

A producer of pipes ranging in diameter from 50mm to 2m

has a x-ray testing systems integrated to the end of their

production lines to ensure the pipes they manufacture will not

leak and are impermeable. Pipes for pipelines for example

must resist long-term exposure to harsh environments and

withstand high pressures and fluctuations in temperature.

Therefore, they must be guaranteed to be free from material

faults and weak points, such as flaws in the weld seam, like

trapped air or slag in the metal.

The final inspection of the pipe involves the pipes entering an

x-ray test room, which is a radiation-proof bunker. The x-ray

source is positioned precisely over the pipe, while a flat panel

forms the opposite pole of the system. The flat panel is located

inside a large pipe or below a small one.

Accurate positioning of pipe, the flat panel and the x-ray

source is crucial to achieving optimum test results and

therefore accurate and reliable sensors are critical to

production efficiency.

.

CUSTOMER VALUES

ACCURATE HIGH-SPEED MEASUREMENT OF FAST-MOVING

MATERIAL

DISCRETE RAW-DATA OUTPUT WITH EXCEPTIONAL

RESOLUTION

REAL-TIME PROCESS MONITORING AND ADJUSTMENT

HIGHLY RELIABLE, COST-EFFECTIVE SOLUTION

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT

HIGH-SPEED MEASUREMENT WITH AN EXCEPTIONAL

RESOLUTION

CUSTOMER SOLUTION

Contrinex Analogue Output Inductive sensors are highly

accurate and provide the continuous voltage or current

outputs required for this application. The quasi-embeddable

sensors feature a chrome-plated brass body and PBTP sensing

face, with the M18-diameter sensor allowing sensing distances

up to 10mm (0.4”) with resolution in the µm range.

The sensor, mounted in the sensing head, moves rapidly back

and forth across the web and senses through the material of

the web as it feeds over the roller. It measures the distance

from its sensing face – which lies a known distance from the

bottom face of the head, to the top surface of the roller. It

delivers a precisely calibrated, near-linear, discrete output in

the range 0 to 10V or 4 to 20mA.

The Contrinex inductive sensor has a sealed cable entry,

ensuring fit-and-forget capability during extended periods of

operation, and connects with the machine’s control system via

a flexible PUR-sheathed cable. Using a custom-configured

software interface, output data is displayed numerically and

graphically on a screen, allowing real-time adjustment to the

production process when necessary.

Contrinex’s Analogue Output sensors provide a cost-effective

solution that satisfies the customer’s requirements for

accurate high-speed measurement with an exceptional

resolution. These analogue inductive sensors are used on an

almost unimaginable array of applications and industries.

.

A specialised textile-testing machine measures the thickness

of a moving textile web in real at a high-speed. As the web

passes over a roller, a precision Contrinex analogue inductive

sensor, positioned directly above the roller, rests lightly on the

top of the web. It senses the distance through the material to

the roller, precisely measuring the thickness of the material.

CUSTOMER APPLICATION

For the efficient manufacture of textiles and fabrics, the

thickness of the material needs to be measured immediately

after its formation to enable real-time adjustment of the

production process. Therefore, a manufacturer of specialised

textile-testing machines uses a high-accuracy sensor to

measure the thickness of a continuously produced sheet, or

web of material moving at up to 5m/s (16.4fps).

Measurements are required across the full width of the textile

web, which can be up to 4 metre (13ft) wide. To achieve this a

sensing head is mounted on a transverse-axis carriage which

lies immediately above a fixed roller, traversing the width of

the web as it passes over the roller. In this application, the

precision sensor is providing real-time measurements in the

range 0 to 4mm with a resolution of 0.02mm (0.0008”) or

better.

High-frequency measurement is provided to accommodate

the speed and width of the moving web. A continuous

analogue output is necessary as conventional digital sensors

do not provide the required resolution.

.

CUSTOMER VALUES

MAXIMUM VEHICLE UTILISATION WITH FEWER CONSTRAINTS

ON OPERATIONS

REAL-TIME INDICATION OF BEARING CONDITION AND WEAR

RATE

REDUCED MAINTENANCE COSTS WITH MINIMAL INCIDENCE OF

BREAKDOWNS

RELIABLE OPERATION IN A HIGHLY DEMANDING AND HARSH

ENVIRONMENT

PRODUCT ADVANTAGES

ANALOGUE DEVICE WITH EXTENDED 40MM SENSING RANGE

SMALL PHYSICAL SIZE (LESS THAN 50MM LENGTH)

EXCEPTIONAL ACCURACY AND RESOLUTION IN THE MICRON

RANGE

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

Busy container seaports rely upon the ‘24/7’ operation of

specialist container-handling vehicles called Straddle Carriers

for loading, unloading and stacking containers. Often located

at ports, being beside the sea can mean that they have to work

in an aggressive and corrosive environment, requiring

frequent maintenance.

Because traditional, interval-based maintenance schedules are

not optimally efficient, condition-based intervention systems

which minimise the risk of breakdown, are popular. European

port operators therefore frequently rely upon Contrinex’s

rugged, analogue-output inductive sensors to monitor

components with a high risk of premature failure, maximising

vehicle utilisation and reducing maintenance costs.

CUSTOMER APPLICATION

A fleet of straddle carriers services a busy container port,

operating round the clock in a highly aggressive environment.

Frequent maintenance is necessary, but traditional, interval-

based maintenance schedules are not always optimal.

Condition-based intervention minimises the risk of

breakdowns, while imposing fewer constraints on day-to-day

operation; it also incurs cost only when necessary.

As a carrier moves over a container, a central spreader beam

lowers and locks onto the four corner fittings of the container.

Plain plastic bearings on the carrier legs guide the container as

it is raised; there is significant contamination from dirt and

other debris. Bearings wear rapidly in the all-weather

operating conditions.

A condition-monitoring system must measure bearing

thickness, repeatably and accurately, in realtime and with µm

resolution. Sensors must operate reliably in the harsh

environment with a minimum rating of IP67. Sensor length

must not exceed 70mm and a minimum sensing range of

30mm is mandatory.

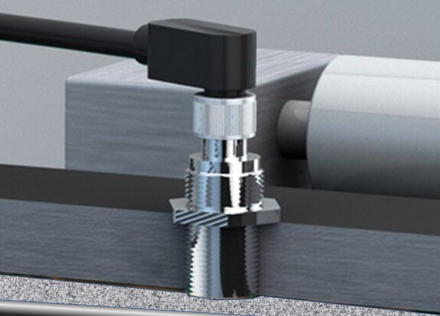

CUSTOMER SOLUTION

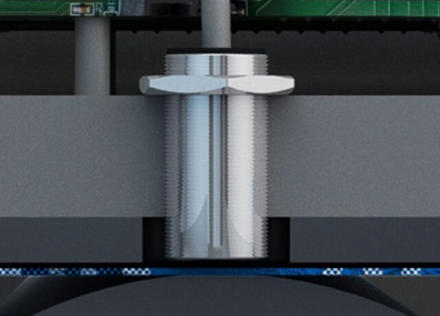

Contrinex’s Analogue Inductive sensors, which feature ‘Extra

Distance’ technology are ideal for this demanding application.

These M30-diameter metal-bodied devices are IP67-rated and

provide an analogue voltage (0 to 10 volt) or current (4 to

20mA) output. The sensors are less than 50mm long with a

40mm sensing range, comfortably exceeding the specified

requirement.

A mild steel mounting plate, fixed immediately behind the

plastic bearing, locates each sensor with its sensing face in

contact with the rear surface of the bearing. As a container

passes over the front face of the bearing, the sensor measures

the distance to the metal container wall, and thus the bearing

thickness. Data is collected in real time with exceptional

accuracy and resolution in the micron range.

Data passes to on-board computers mounted on each carrier;

connection is via a flexible cable with an easily detachable M12

connector. At intervals, carriers transmit data wirelessly to a

central processor for detailed analysis.

The output gives a clear indication of the condition and wear

rate of each bearing, identifying any carrier requiring

maintenance. Consequently, the port operator has the means

to develop a genuine commercial advantage by eliminating

compromise from day-to-day operating processes

CONTRINEX’S BEST-IN-CLASS ANALOGUE INDUCTIVE SENSORS ARE ACCURATE TO MICRONS (µM)

AND TRUSTED IN A WIDE VARIETY OF CRITICAL SYSTEMS AND INNOVATIVE MACHINES.

ANALOGUE INDUCTIVE SENSORS

ANALOGUE INDUCTIVE SENSORS - EXCEPTIONAL ACCURACY & AFFORDABILITY

PRODUCT ADVANTAGES

EXCEPTIONAL ACCURACY & RESOLUTION IN MICRON RANGE

HIGH-SPEED MEASUREMENT WITH AN EXCEPTIONAL

RESOLUTION, PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT

BEST-IN-CLASS TEMPERATURE STABILITY

VERY LONG SENSING RANGES UP TO 40MM

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

Contrinex’s analogue inductive sensors offer a reliable, repeatable, highly accurate means of measuring the position of a target

object. Best-in-class temperature stability and a measurement range of zero to 40mm make the sensors ideally suited for measuring

linear, angular and rotational position.

With detection accuracy in the micron range and the best long-range sensing capability on the market, Contrinex analogue sensors

offer world-class performance with an attractive total cost of ownership.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

--

CUSTOMER VALUES

CONTINUOUS PRODUCTION AS IN-PROCESS MEASUREMENT IS

HIGHLY ACCURATE WITH HIGH SAMPLING RATE

DEFECTS IDENTIFIED IN REAL TIME MINIMISES REJECT COSTS

NO RESTRICTIONS ON MOUNTING POSITION AS SENSORS ARE

VIBRATION-RESISTANT AND TEMPERATURE-STABLE

COMPATIBILITY WITH EXISTING IN-HOUSE SYSTEMS 0 TO 10V

LONG SENSING DISTANCE MINIMISES RISK OF MECHANICAL

DAMAGE TO THE SENSOR

PRODUCT ADVANTAGES

EXCEPTIONAL DETECTION ACCURACY, EXCELLENT

REPEATABILITY AND RESOLUTION IN THE MICRON RANGE (µM)

SAMPLING RATE OF 250HZ

CONDIST® TECHNOLOGY PROVIDES EXTENDED SENSING

RANGE ≤ 10 MM

RUGGED, VIBRATION-RESISTANT WITH METAL HOUSINGS

INDUSTRY-STANDARD 0 TO 10V ANALOGUE OUTPUTS

A manufacturer of industrial timing belts trusts Contrinex’s

analogue inductive sensors to measure the position of steel

reinforcing bands during continuous production.

Two long-range, high-resolution sensors, mounted above the

extruded belt profile, provide real-time positional data. The

customer’s process-control system monitors the sensor’s

analogue voltage outputs, alerting the operator and halting

production if the values are outside allowable limits.

CUSTOMER APPLICATION

To enhance the strength of industrial timing belts, steel

reinforcing wires are bonded into the belt carcass as part of a

continuous extrusion process. The distance between the

reinforcing wires and the belt teeth is a critical parameter,

influencing the accuracy of the belt’s fit and other operating

characteristics, including service life.

Engineers can check product quality at intervals by cutting

samples of extruded belts and taking optical measurements,

but this process is slow and only detects faults some time after

production is complete, leading to high reject costs.

The customer requires a real-time system with sensors that

reliable and accurately measure the position of the steel

reinforcement.

CUSTOMER SOLUTION

Contrinex M18-size analogue inductive sensors are ideal for this

application providing an analogue voltage output with a

sampling rate of at least 100Hz. The physical characteristics of

the belt dictate a sensing distance of up to 10 mm with micron

(µm) measurement accuracy. Contrinex’s patented Condist®

technology provides a highly stable sensing performance at

operating distances of ≤10 mm with exceptional detection

accuracy, excellent repeatability and resolution in the micron

range.

The sensors sample at 250Hz, enabling accurate measurement

of the position of the steel reinforcement in the fast moving

belt profile, and provide continuous, non-linearised 0 to 10V

analogue output signals. They are resistant to vibration and

variations in ambient temperature, allowing their positioning

immediately after the extrusion press in close proximity to the

moving belt.

Two sensors, set flush into a non-metallic plate, are mounted

directly above the surface of the belt as it runs over a guide

roller, giving a stable reference position. The lightly tensioned

belt clears the sensing face of the devices by a few tenths of a

millimetre. Connection to the customer’s control system is via

a flexible cable with an easily detachable M12 connector.

The introduction of Contrinex analogue inductive sensors

provide small, high-accuracy, ultra-reliable sensors with a low

total cost of ownership.

Rather than needing to destructively test belts to inspect the

position of the steel reinforcement and risking high reject

costs because of the infrequent nature of the sampling, the

production process is now continuously monitored.

CUSTOMER VALUES

HIGH-SPEED CHECKING OF DIFFERENT CAN TYPES

SINGLE SOLUTION TO CHECK DIFFERENT CAN TYPES

SIMPLE INSTALLATION - DIRECT INTERFACE TO CONTROLLER

(0 – 10 VDC OR 4 – 20 MA)

LONG SERVICE LIFE, HIGHLY RELIABLE, COST-EFFECTIVE

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG SENSING RANGE OF 40MM

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT, RESOLUTION

IN µM RANGE

EXCELLENT TEMPERATURE STABILITY & VERY GOOD

REPEATING ACCURACY

SEVERAL SWITCH POINTS WITH A SINGLE DEVICE

LONG SENSING DISTANCE COMPARED TO COMPETITORS

CUSTOMER SOLUTION

Analogue inductive sensors from Contrinex’s 509 Series are

ideal for this application because their Condist® oscillator

technology ensures excellent environmental stability,

especially to temperature. This is key in providing sensing

distances up to 3 times the standard (in this case 40 mm from

the M30 sized sensor).

This extra sensing distance ability enables them to obtain a

good signal not only through multiple layers of cardboard, but

also from different conductive metals at varying distances,

depending on the can type.

The customer mounted the M30 sized inductive analogue

sensors which yield the greatest sensing distance above and

below the passing lanes of cans, so that the double layer of

cans in each carton can be checked through the cardboard

walls of the box.

The continuous analogue current or voltage output from

these sensors is connected directly to a PLC with a high-speed

analogue input card. Resolution is in the µm range and repeat

accuracy is very good. The solution excels because it is durable,

adaptable, reliable and simple to install.

.

To ensure that sealed cardboard cartons have the required

number of tinned food cans inside them, a packaging

company trusts Contrinex’s analogue inductive sensors. Using

an analogue sensor enables this final pre-shipment quality

check to process different sizes of can as well as manage with

different material grades of can.

CUSTOMER APPLICATION

Canned products and their labels are protected during

delivery by being tightly packed into sturdy sealed cardboard

boxes. This poses a challenge to food packaging companies

because retailers, particularly supermarkets require absolute

accuracy in the cartons contents, but at final inspection the

carton is already sealed and so the contents can not be visually

inspected.

Therefore to eliminate the risk that product faults that may

have occurred during upstream processes are shipped out to

the customers, the packing company needed a way to verify

what tins are inside the sealed box. Because of the packaging

line handles a variety of cans of different sizes and materials, a

conventional on-off switching inductive proximity sensor could

not be used.

An additional challenge is that the the sensor needs to be part

of a verification process integrated into a fast-moving

automated packaging and pre-shipment line, accepting or

rejecting each carton instantly.

.

CUSTOMER VALUES

HIGH-SPEED CHECKING OF DIFFERENT CAN TYPES

SINGLE SOLUTION TO CHECK DIFFERENT CAN TYPES

SIMPLE INSTALLATION - DIRECT INTERFACE TO CONTROLLER

(0 – 10 VDC OR 4 – 20 MA)

LONG SERVICE LIFE, HIGHLY RELIABLE, COST-EFFECTIVE

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG SENSING RANGE OF 40MM

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT, RESOLUTION

IN µM RANGE

EXCELLENT TEMPERATURE STABILITY & VERY GOOD

REPEATING ACCURACY

SEVERAL SWITCH POINTS WITH A SINGLE DEVICE

LONG SENSING DISTANCE COMPARED TO COMPETITORS

CUSTOMER SOLUTION

Contrinex analogue inductive sensors from their Extra

Distance 509 Series family are perfect for the position and

distance measurement requirements of this application. The

sensors provide an analogue value for the entire motion

sequence of the x-ray inspection. Their excellent resolution in

µm range is particularly suitable for measuring gaps and

angles, detecting motion and controlling travel smoothly.

The sensors are positioned to measure both the pipe carriage

position, which represents the system’s zero-point and is

therefore critical for correct operation and the distance

between the x-ray source and the pipe surface which is critical

to x-ray result quality.

The analogue sensors output a continuous voltage or current

analogue signal which reflects the gap between the damping

element and the sensing surface.

With Contrinex’s patent-protected Condist technology, these

high-performance analogue sensors provide a sensing range

that is more than twice the distance offered by competitors.

The M30 versions used in this application offer a sensing range

of 0 to 40 mm and so they can provide the flexibility required

for testing the numerous pipe diameters being manufactured.

The solution excels because it is durable, adaptable, reliable

and was also fast and simple to install.

.

The integrity of weld seams in pipes used to transport oil or

gas across land or sea is ensured using x-ray testing. The x-ray

test systems used for this require precision control of the

distance between the x-ray source and the surface of the pipe

because this is critical for the quality of the imaging data.

CUSTOMER APPLICATION

A producer of pipes ranging in diameter from 50mm to 2m

has a x-ray testing systems integrated to the end of their

production lines to ensure the pipes they manufacture will not

leak and are impermeable. Pipes for pipelines for example

must resist long-term exposure to harsh environments and

withstand high pressures and fluctuations in temperature.

Therefore, they must be guaranteed to be free from material

faults and weak points, such as flaws in the weld seam, like

trapped air or slag in the metal.

The final inspection of the pipe involves the pipes entering an

x-ray test room, which is a radiation-proof bunker. The x-ray

source is positioned precisely over the pipe, while a flat panel

forms the opposite pole of the system. The flat panel is located

inside a large pipe or below a small one.

Accurate positioning of pipe, the flat panel and the x-ray

source is crucial to achieving optimum test results and

therefore accurate and reliable sensors are critical to

production efficiency.

.

CLICK ON AN IMAGE TO VIEW THE BROCHURE,

READ APPLICATION EXAMPLES BELOW, CLICK

HERE TO VIEW THIS SENSOR ON CONTRINEX’S

WEBSITE, OR CALL US TO HELP GUIDE YOU

THROUGH SELECTION, ANSWER QUESTIONS, OR

TO HELP YOU #MAKESENSEOFSENSORS:

ANALOGUE INDUCTIVE

SENSORS

CONTRINEX’S BEST-IN-CLASS ANALOGUE INDUCTIVE

SENSORS ARE ACCURATE TO MICRONS (µM) AND

TRUSTED IN A WIDE VARIETY OF CRITICAL SYSTEMS

AND INNOVATIVE MACHINES.

Busy container seaports rely upon the ‘24/7’ operation of

specialist container-handling vehicles called Straddle Carriers

for loading, unloading and stacking containers. Often located

at ports, being beside the sea can mean that they have to work

in an aggressive and corrosive environment, requiring

frequent maintenance.

Because traditional, interval-based maintenance schedules are

not optimally efficient, condition-based intervention systems

which minimise the risk of breakdown, are popular. European

port operators therefore frequently rely upon Contrinex’s

rugged, analogue-output inductive sensors to monitor

components with a high risk of premature failure, maximising

vehicle utilisation and reducing maintenance costs.

CUSTOMER APPLICATION

A fleet of straddle carriers services a busy container port,

operating round the clock in a highly aggressive environment.

Frequent maintenance is necessary, but traditional, interval-

based maintenance schedules are not always optimal.

Condition-based intervention minimises the risk of

breakdowns, while imposing fewer constraints on day-to-day

operation; it also incurs cost only when necessary.

As a carrier moves over a container, a central spreader beam

lowers and locks onto the four corner fittings of the container.

Plain plastic bearings on the carrier legs guide the container as

it is raised; there is significant contamination from dirt and

other debris. Bearings wear rapidly in the all-weather

operating conditions.

A condition-monitoring system must measure bearing

thickness, repeatably and accurately, in real-time and with µm

resolution. Sensors must operate reliably in the harsh

environment with a minimum rating of IP67. Sensor length

must not exceed 70mm and a minimum sensing range of

30mm is mandatory.

CUSTOMER SOLUTION

Contrinex Analogue Output Inductive sensors are highly

accurate and provide the continuous voltage or current

outputs required for this application. The quasi-embeddable

sensors feature a chrome-plated brass body and PBTP sensing

face, with the M18-diameter sensor allowing sensing distances

up to 10mm (0.4”) with resolution in the µm range.

The sensor, mounted in the sensing head, moves rapidly back

and forth across the web and senses through the material of

the web as it feeds over the roller. It measures the distance

from its sensing face – which lies a known distance from the

bottom face of the head, to the top surface of the roller. It

delivers a precisely calibrated, near-linear, discrete output in

the range 0 to 10V or 4 to 20mA.

The Contrinex inductive sensor has a sealed cable entry,

ensuring fit-and-forget capability during extended periods of

operation, and connects with the machine’s control system via

a flexible PUR-sheathed cable. Using a custom-configured

software interface, output data is displayed numerically and

graphically on a screen, allowing real-time adjustment to the

production process when necessary.

Contrinex’s Analogue Output sensors provide a cost-effective

solution that satisfies the customer’s requirements for

accurate high-speed measurement with an exceptional

resolution. These analogue inductive sensors are used on an

almost unimaginable array of applications and industries.

A specialised textile-testing machine measures the thickness

of a moving textile web in real at a high-speed. As the web

passes over a roller, a precision Contrinex analogue inductive

sensor, positioned directly above the roller, rests lightly on the

top of the web. It senses the distance through the material to

the roller, precisely measuring the thickness of the material.

CUSTOMER APPLICATION

For the efficient manufacture of textiles and fabrics, the

thickness of the material needs to be measured immediately

after its formation to enable real-time adjustment of the

production process. Therefore, a manufacturer of specialised

textile-testing machines uses a high-accuracy sensor to

measure the thickness of a continuously produced sheet, or

web of material moving at up to 5m/s (16.4fps).

Measurements are required across the full width of the textile

web, which can be up to 4 metre (13ft) wide. To achieve this a

sensing head is mounted on a transverse-axis carriage which

lies immediately above a fixed roller, traversing the width of

the web as it passes over the roller. In this application, the

precision sensor is providing real-time measurements in the

range 0 to 4mm with a resolution of 0.02mm (0.0008”) or

better.

High-frequency measurement is provided to accommodate

the speed and width of the moving web. A continuous

analogue output is necessary as conventional digital sensors

do not provide the required resolution.

CUSTOMER VALUES

MAXIMUM VEHICLE UTILISATION WITH FEWER CONSTRAINTS

ON OPERATIONS

REAL-TIME INDICATION OF BEARING CONDITION AND WEAR

RATE

REDUCED MAINTENANCE COSTS WITH MINIMAL INCIDENCE OF

BREAKDOWNS

RELIABLE OPERATION IN A HIGHLY DEMANDING AND HARSH

ENVIRONMENT

PRODUCT ADVANTAGES

ANALOGUE DEVICE WITH EXTENDED 40MM SENSING RANGE

SMALL PHYSICAL SIZE (LESS THAN 50MM LENGTH)

EXCEPTIONAL ACCURACY AND RESOLUTION IN THE MICRON

RANGE

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

CUSTOMER SOLUTION

Contrinex’s Analogue Inductive sensors, which feature ‘Extra

Distance’ technology are ideal for this demanding application.

These M30-diameter metal-bodied devices are IP67-rated and

provide an analogue voltage (0 to 10 volt) or current (4 to

20mA) output. The sensors are less than 50mm long with a

40mm sensing range, comfortably exceeding the specified

requirement.

A mild steel mounting plate, fixed immediately behind the

plastic bearing, locates each sensor with its sensing face in

contact with the rear surface of the bearing. As a container

passes over the front face of the bearing, the sensor measures

the distance to the metal container wall, and thus the bearing

thickness. Data is collected in real time with exceptional

accuracy and resolution in the micron range.

Data passes to on-board computers mounted on each carrier;

connection is via a flexible cable with an easily detachable M12

connector. At intervals, carriers transmit data wirelessly to a

central processor for detailed analysis.

The output gives a clear indication of the condition and wear

rate of each bearing, identifying any carrier requiring

maintenance. Consequently, the port operator has the means

to develop a genuine commercial advantage by eliminating

compromise from day-to-day operating processes.

CUSTOMER VALUES

ACCURATE HIGH-SPEED MEASUREMENT OF FAST-MOVING

MATERIAL

DISCRETE RAW-DATA OUTPUT WITH EXCEPTIONAL

RESOLUTION

REAL-TIME PROCESS MONITORING AND ADJUSTMENT

HIGHLY RELIABLE, COST-EFFECTIVE SOLUTION

PRODUCT ADVANTAGES

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT

HIGH-SPEED MEASUREMENT WITH AN EXCEPTIONAL

RESOLUTION

ANALOGUE INDUCTIVE SENSORS -

EXCEPTIONAL ACCURACY & AFFORDABILITY

PRODUCT ADVANTAGES

EXCEPTIONAL ACCURACY & RESOLUTION IN MICRON RANGE

HIGH-SPEED MEASUREMENT WITH AN EXCEPTIONAL

RESOLUTION, PRECISELY CALIBRATED, NEAR-LINEAR OUTPUT

BEST-IN-CLASS TEMPERATURE STABILITY

VERY LONG SENSING RANGES UP TO 40MM

CONTINUOUS MEASUREMENT WITH CURRENT OR VOLTAGE

ANALOGUE SIGNAL

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

Contrinex’s analogue inductive sensors offer a reliable,

repeatable, highly accurate means of measuring the position of

a target object. Best-in-class temperature stability and a

measurement range of zero to 40mm make the sensors ideally

suited for measuring linear, angular and rotational position.

With detection accuracy in the micron range and the best long-

range sensing capability on the market, Contrinex analogue

sensors offer world-class performance with an attractive total

cost of ownership.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS