(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE DOUBLE-SHEET DETECTION ELIMINATES TOOL

DAMAGE AND DOWNTIME

COMPACT, ROBUST SENSOR ENSURES CONVENIENT,

UNOBTRUSIVE OPERATION

INCREASED FLEXIBILITY AS A SINGLE SENSOR DETECTS

SEVERAL DIFFERENT MATERIALS (EG CARBON STEEL,

STAINLESS STEEL & ALUMINIUM)

REDUCED COMPLEXITY AS SENSOR CONNECTS DIRECTLY TO

THE CUSTOMER’S CONTROL SYSTEM

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

CONDET® TECHNOLOGY MAKES PERFORMANCE

INDEPENDENT OF TARGET MATERIAL

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

Contrinex’s innovative sensors provide affordable detection of

overlapping metal sheets. They can protect a press-line by

checking that two metal blanks are not presented to the

forming press, or alternatively ensure two pieces of metal are

present for example in an automotive welding assembly –

Sometimes two’s too many, but sometimes you just need two.

CUSTOMER APPLICATION

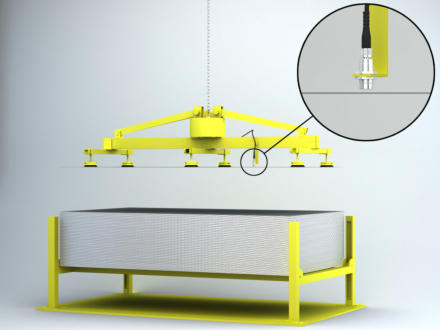

A producer of deep-drawn metal parts for the automotive

industry uses Contrinex’s double-sheet sensing to prevent

costly tool damage and downtime.

Deep drawing and other metal-forming techniques are widely

used in the automotive industry, which requires expensive

press tools to produce complex profiles from sheet metal

blanks. During high-volume production, an automated feeder

loads sheets of steel or aluminium to the press.

The metal sheets are lightly lubricated to reduce friction

during deep drawing, but the thin film of oil can cause two

sheets to stick together in the feeder. If the press operates with

such double sheets loaded, the forming tool will be damaged,

resulting in downtime and large repair costs. Therefore

sensing systems are used to check the material before it is

loaded.

Previously, the customer had trailed alternative sensor

technologies. All were excessively cumbersome and difficult to

set up, and most were unable to detect double sheets reliably.

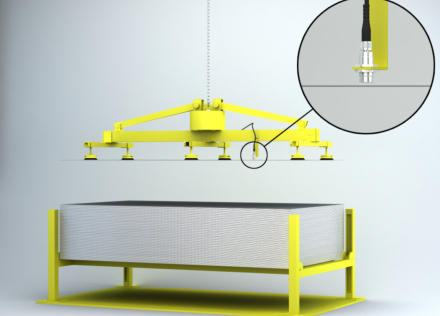

APPLICATION - DOUBLE-SHEET DETECTION

SENSORS PROTECT PRESS LINES & IMPROVE OEE

Customer Solution

Contrinex offers a rugged, compact stainless-steel -bodied

sensor for the loading station, which checks each metal sheet

as it is presented by the feeder. If it detects a double sheet, the

material is rejected and the operating cycle inhibited, which

reduces expensive damage to tooling and improves OEE.

The sensor enables discrimination between single and double

metal sheets of a defined thickness of steel or aluminium in

the size range of 0.8 – 1.2mm thick.

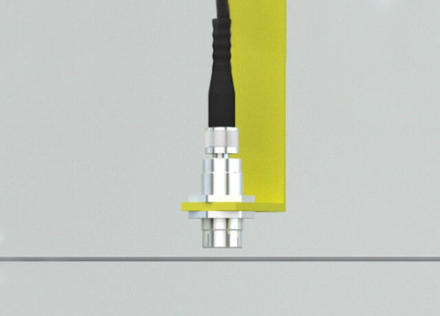

A specialist version of Contrinex’s uniquely robust ‘700 Series’

family of inductive sensors, they share the benefits of being

both impact and abrasion resilient and having a case

machined from a single-piece of stainless-steel – These are the

sensors whose robustness is demonstrated by using them to

hammer in nails.

The reliability of their performance and robustness enable you

to minimise downtime and improve the OEE of Press-lines or

verify assembly operations.

CONTRINEX’S INNOVATIVE DOUBLE-SHEET DETECTION SENSORS RELIABLY DETECT

SINGLE OR DOUBLE SHEETS OF STEEL, STAINLESS-STEEL OR ALUMINIUM -

PROTECT A PRESS LINES FROM MIS-FEEDS OR ENSURE THE ASSEMBLY OF TWO METAL SHEETS

DOUBLE-SHEET DETECTION - 700 SERIES INDUCTIVE

Contrinex’s 700 Series includes a special if not ‘magical’

Double-sheet Detection Sensor which utilises inductive

technology to discriminate between one and two conductive

metal sheets of a defined thickness, in the range of 0.8 – 1.2 mm

per sheet.

This discrimination aids in the prevention of double feeds into

blanking and forming processes which ultimately saves

damage to tooling. Alternatively it can assure that two metal

pieces are supplied to an assembly operation.

The one-piece, stainless-steel construction of these sensors

makes them the most durable on the market. They withstand

the impacts that are a common hazard in double-sheet

detection applications, ensuring minimal down-time.

DOUBLE SHEET INDUCTIVE SENSORS -MAGICAL DETECTION AT AN AFFORDABLE PRICE

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

VIDEO , READ THE APPLICATION EXAMPLES

BELOW, CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP

GUIDE YOU THROUGH SELECTION, ANSWER

QUESTIONS, OR TO HELP YOU

#MAKESENSEOFSENSORS:

DOUBLE-SHEET DETECTION

- 700 SERIES INDUCTIVE

CONTRINEX’S INNOVATIVE DOUBLE-SHEET DETECTION

SENSORS RELIABLY DETECT SINGLE OR DOUBLE SHEETS

OF STEEL, STAINLESS-STEEL OR ALUMINIUM -

PROTECT A PRESS LINES FROM MIS-FEEDS OR

ENSURE THE ASSEMBLY OF TWO METAL SHEETS

Contrinex’s innovative sensors provide affordable detection of

overlapping metal sheets. They can protect a press-line by

checking that two metal blanks are not presented to the

forming press, or alternatively ensure two pieces of metal are

present for example in an automotive welding assembly –

Sometimes two’s too many, but sometimes you just need two.

CUSTOMER APPLICATION

A producer of deep-drawn metal parts for the automotive

industry uses Contrinex’s double-sheet sensing to prevent

costly tool damage and downtime.

Deep drawing and other metal-forming techniques are widely

used in the automotive industry, which requires expensive

press tools to produce complex profiles from sheet metal

blanks. During high-volume production, an automated feeder

loads sheets of steel or aluminium to the press.

The metal sheets are lightly lubricated to reduce friction

during deep drawing, but the thin film of oil can cause two

sheets to stick together in the feeder. If the press operates with

such double sheets loaded, the forming tool will be damaged,

resulting in downtime and large repair costs. Therefore

sensing systems are used to check the material before it is

loaded.

Previously, the customer had trailed alternative sensor

technologies. All were excessively cumbersome and difficult to

set up, and most were unable to detect double sheets reliably.

CUSTOMER VALUES

RELIABLE DOUBLE-SHEET DETECTION ELIMINATES TOOL

DAMAGE AND DOWNTIME

COMPACT, ROBUST SENSOR ENSURES CONVENIENT,

UNOBTRUSIVE OPERATION

INCREASED FLEXIBILITY AS A SINGLE SENSOR DETECTS

SEVERAL DIFFERENT MATERIALS (EG CARBON STEEL,

STAINLESS STEEL & ALUMINIUM)

REDUCED COMPLEXITY AS SENSOR CONNECTS DIRECTLY TO

THE CUSTOMER’S CONTROL SYSTEM

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

CONDET® TECHNOLOGY MAKES PERFORMANCE

INDEPENDENT OF TARGET MATERIAL

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

Customer Solution

Contrinex offers a rugged, compact stainless-steel -bodied

sensor for the loading station, which checks each metal sheet

as it is presented by the feeder. If it detects a double sheet, the

material is rejected and the operating cycle inhibited, which

reduces expensive damage to tooling and improves OEE.

The sensor enables discrimination between single and double

metal sheets of a defined thickness of steel or aluminium in

the size range of 0.8 – 1.2mm thick.

A specialist version of Contrinex’s uniquely robust ‘700 Series’

family of inductive sensors, they share the benefits of being

both impact and abrasion resilient and having a case

machined from a single-piece of stainless-steel – These are the

sensors whose robustness is demonstrated by using them to

hammer in nails.

The reliability of their performance and robustness enable you

to minimise downtime and improve the OEE of Press-lines or

verify assembly operations.

Contrinex’s 700 Series includes a special if not ‘magical’

Double-sheet Detection Sensor which utilises inductive

technology to discriminate between one and two conductive

metal sheets of a defined thickness, in the range of 0.8 – 1.2 mm

per sheet.

This discrimination aids in the prevention of double feeds into

blanking and forming processes which ultimately saves

damage to tooling. Alternatively it can assure that two metal

pieces are supplied to an assembly operation.

The one-piece, stainless-steel construction of these sensors

makes them the most durable on the market. They withstand

the impacts that are a common hazard in double-sheet

detection applications, ensuring minimal down-time.

DOUBLE SHEET INDUCTIVE SENSORS -

AFFORDABLE MAGICAL DETECTION

PRODUCT ADVANTAGES

SENSOR SPECIALLY DEVELOPED FOR DETECTING MULTIPLE

OVERLAPPING METAL SHEETS

RUGGED INDUCTIVE SENSOR WITH ONE-PIECE STAINLESS

STEEL CONSTRUCTION

EXTENDED SENSING DISTANCE AVOIDS RISK OF MECHANICAL

DAMAGE

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS