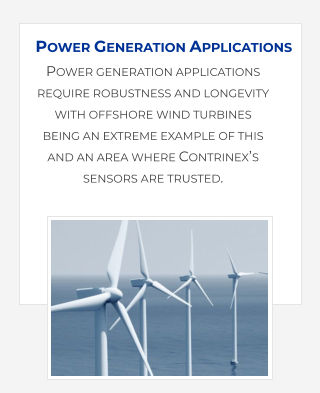

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

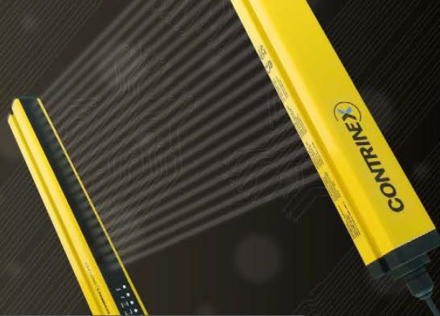

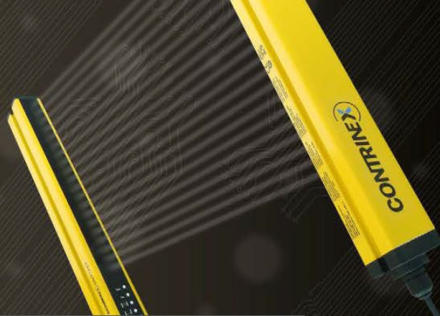

PRODUCT ADVANTAGES - ‘BASIC’ LIGHT CURTAINS

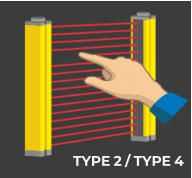

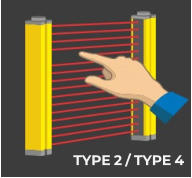

CATEGORY 2 OR 4, PL C/E ACCORDING TO EN/ISO 13849-1

TYPE 2 OR 4 ACCORDING TO IEC 61496-1 AND -2

RESOLUTION: 30 MM - CERTIFIED TÜV, CE

PROTECTIVE HEIGHT: 150 / 279MM TO 1,827MM (TYPE 2/4)

OPERATING RANGE: 0.25 TO 12M

TEMPERATURE −35 … +60°C (BASIC) / 0 … +55°C (SLIM)

2-CHANNEL SELECTION - OPTICAL SYNCHRONIZATION

PERMANENT AUTOCONTROL - LOW POWER CONSUMPTION

STANDARD HOUSING (42 × 48MM) - IP65, IP67

SLIM HOUSING (26× 26MM) - IP65

PRODUCT ADVANTAGES - ‘ADVANCED SLIM’ CURTAINS

CATEGORY 4, PL E ACCORDING TO EN/ISO 13849-1

TYPE 4 ACCORDING TO IEC 61496-1 AND -2

RESOLUTION: 30 MM - CERTIFIED TÜV, CE

PROTECTIVE HEIGHT: 170 TO 1,610MM

OPERATING RANGE: 0.25 TO 5M

OPERATING TEMPERATURE −35 … +60°C (−31 … +140°F)

2-CHANNEL SELECTION - OPTICAL SYNCHRONIZATION

PERMANENT AUTOCONTROL - LOW POWER CONSUMPTION

STANDARD HOUSING (42 × 48MM) - IP65, IP67

SLIM HOUSING (26× 26MM) - IP65

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

HAND RESOLUTION (30MM) TYPE 2 & TYPE 4 SAFETY LIGHT CURTAINS PROVIDE COST-EFFECTIVE CHOICES

WHENEVER SAFETY REQUIREMENTS ARE MODERATE AND THE RISK ASSESSMENT ALLOW THEIR USE.

A WIDE SELECTION OF FEATURES FROM THE BASIC, BASIC SLIM & EXTENDED SLIM FAMILIES.

SAFETY LIGHT CURTAINS - HAND RESOLUTION (30MM)

TYPE 2 & TYPE 4 SAFETY LIGHT CURTAINS - HAND RESOLUTION (30MM) - LOTS OF CHOOSE

If the risk assessment allows for their use, Type 2 Light Curtains are a cost-effective choice for which Contrinex offers parts from its

BASIC (42 x 48mm), or BASIC SLIM (26 x 26mm) ranges.

For Type 4 requirements, light curtains are offered in the BASIC (42 x 48mm) and EXTENDED SLIM (26 x 26mm) ranges..

The BASIC and BASIC SLIM range offers robust extruded housing (42 x 48mm, or 26 x 26mm respectively) , TÜV, CE and UL-

certification according to IEC 61496-1 and -2 and ISO 13849-1. They feature permanent autocontrol and low power consumption with

easy and low-cost installation provided by their use of an integral 5-pin M12 connector or pigtail.

The EXTENDED SLIM range are all Type 4 light curtains which are TÜV, CE and UL certified according to IEC 61496-1 and 2, IEC 61508-

1/2/3 and ISO 13849-1. Protective heights range from 170 to 1610 mm with integrated EDM*, restart interlock and beam coding. Since

EDM includes a relay monitoring function, users can also avoid the cost of wired relays.

The slim housing (26mm x 26mm) enables blind-zone free installation and connection is via an integral 5-pin or 8-pin M12 pigtail.

Bluetooth(R) wirless connectivity for configured and monitoring is offered using a free smartphone app – A world first!

CUSTOMER VALUES

MEETS HIGHEST SAFETY REQUIREMENTS ECONOMICALLY

RELIABLE AND ADAPTABLE

EASY TO INSTALL

FAIL-SAFE ELECTRONIC DESIGN

SECURES LOWER LIABILITY COSTS

PROTECTS EMPLOYEES AND ENVIRONMENT

REDUCES LOSS OF FLUIDS INVOLVED

PRODUCT ADVANTAGES

PERMANENT CERTIFIED CE, TÜV, AND UL

IP 65 AND IP 67 CLASS PROTECTION

CATEGORY 4, PL E ACCORDING TO EN/ISO 13849-1

TYPE 4 ACCORDING TO EN/IEC 61496-1 AND -2

RUGGED CONSTRUCTION

SOIL AND MIST TOLERANT

SIMPLE INSTALLATION

LONG DETECTION RANGE

A high pressure/high temperature degreasing tank line is used

to clean machined metal parts for the automotive industry. To

protect operators from possible injury while degreasing is in

progress, Safetinex YBB-30 safety light curtains have been

installed and connected to the machine control system.

CUSTOMER APPLICATION

The manufacture of automotive parts by stamping or

machining involves liberal use of oily lubricants. However,

these processes leave finished parts heavily laden with oily

residues that must be eliminated prior to assembly. A

degreasing tank line provides the necessary cleaning.

Degreasing tanks contain caustic fluids at high pressure

and/or high temperature, which effectively remove all traces of

lubricant and protective coatings. However, some aspects of

this process are potentially hazardous to both employees and

the environment. The high temperature and pressure at which

cleaning takes place means that anyone accessing the tank

while the process is running risks injury from caustic spray and

harmful vapours.

The containment method chosen must take account of the

need for human interventions, while ensuring operator safety.

Liability costs must be minimized and loss of process fluids

reduced. Electromechanical interlocks were considered, but a

simpler and more operator friendly solution was sought.

CUSTOMER SOLUTION

With their ease of installation and use, Safetinex YBB safety

light curtains were selected for this application. They meet

safety category 4 of EN ISO 13849-1 as well as type 4 of DIN EN

61496-1 and -2.

The safety light curtain comprises a sender and a receiver unit.

Infra-red beams generate a protective field between the two

units. LED displays on the sender and the receiver indicate

field status, operating mode, transmission channel, and

alignment quality. Reliability is guaranteed by a fail-safe

electronic design with permanent autocontrol.

Positioning a safety light curtain near the point of access to

the tank lids prevents the operator from opening them while

cleaning is in progress. The extent of the protective field also

ensures that no operator can access the hazardous area by

reaching over, under or around the light curtain. Any object

entering the protective field will not only disable the spray jets

and stop agitation, but will also cause the control system to

idle before allowing access.

HELPING YOU #MAKE SENSE OF SENSORS

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CLICK ON AN IMAGE TO VIEW THE BROCHURE,

READ APPLICATION EXAMPLES BELOW, CLICK

HERE TO VIEW THE BASIC RANGE OR CLICK

HERE TO VIEW THE EXTENDED SLIM RANGE

ON ON CONTRINEX’S WEBSITE, OR CALL US

TO HELP YOU #MAKESENSEOFSENSORS:

SAFETY LIGHT CURTAINS -

HAND RESOLUTION (30MM)

HAND RESOLUTION (30MM) TYPE 4 SAFETY

LIGHT CURTAINS WITH A SHORT RESPONSE TIME

ARE IDEAL FOR MACHINES WITH LIMITED SPACE.

THE HIGHEST DEGREE OF PROTECTION MAKES

THEM SUITABLE FOR MACHINES WHERE THE

OPERATOR WORKS CLOSE TO THE HAZARD.

THE EXTENDED SLIM CURTAINS OFFER

BLUETOOTH FOR SET-UP & MONITORING

FROM A MOBILE PHONE.

During semi-automated heat staking of assemblies

manufacturers use light curtains to preserve operator safety

without compromising production throughput. The active

optoelectronic protective device (AOPD), mounted directly in

front of each bench-mounted heat-press, prevents the press-

head from descending if it detects any intrusion in the

working area, halting the operating cycle immediately.

CUSTOMER APPLICATION

Heat-staking is a popular process for fastening metal parts to

plastic moldings, and is commonly used by manufacturers

during the production of sub-assemblies. At each station, an

operator loads a molding and one or more metal parts into a

slide-mounted assembly fixture. Once the components are

correctly inserted, the operator pushes the slide into position

beneath the press-head, triggering the automated heat-

staking cycle.

The heated press-head, which may reach temperatures in

excess of 350oC (660oF), descends toward the pre-positioned

components. It applies heat and pressure to specific areas of

the molding, causing a controlled thermal deformation that

creates a permanent joint between the metal parts and the

molding. Following a pre-determined dwell period, the head

returns to the raised position, ending the cycle; the operator

withdraws the slide and removes the assembly from the

fixture.

Existing mechanical safety barriers are cumbersome and

inconvenient; throughput is constrained as a result of the time

taken to open and close the guards during each cycle. The

company requires an alternative safety guard that provides

effective hand protection while allowing unobstructed loading

and unloading. It must be simple, space-saving and operate

reliably in the production environment.

CUSTOMER VALUES

COST-EFFECTIVE, ACTIVE SAFEGUARDING

IMPROVED WORKPLACE ERGONOMICS

INCREASED PRODUCTIVITY ARISING FROM UNIMPEDED

LOADING AND UNLOADING

INDUSTRY-STANDARD INTERFACE REQUIRES MINIMAL

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

PERMANENT AUTOCONTROL NOT USUALLY FOUND ON TYPE 2

SAFETY DEVICES

IP65 AND IP67 PROTECTION

NON-CONTACT OPERATING PRINCIPLES

EXCELLENT SAFETY RATING TO EN/ISO 13849-1 CAT. 2 PL C

AND IEC 61508 SIL 1

AOPD (ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE) WITH

ALUMINIUM HOUSING AND M12 CABLE CONNECTOR

CUSTOMER SOLUTION

The company’s risk assessment confirms that Type 2 AOPDs

(active optoelectronic protective devices) would ensure

appropriate operator protection. Designed for applications

where the risk has been evaluated as moderate, Safetinex IEC

61496 Type 2 light curtains from Contrinex are rated to EN/ISO

13849-1 Category 2, Performance Level PL c and IEC 61508

Safety Integrity Level SIL 1, making them ideal for the

application.

The heat-staking press is housed in an open-fronted enclosure

with clear impact-resistant walls. The light curtain has an

operating range of up to 12 metres and a resolution of 30 mm,

ideal for hand protection; it safeguards the open front area of

the press, allowing easy access when required. The protected

height is 795mm, ensuring safe operation without impeding

the operator during loading and unloading.

Manufactured with rugged extruded aluminium housings and

IP65 + IP67 protection, these units are well-suited to the

production environment and will withstand shocks and

vibrations.

Industry-standard PNP normally-open configuration allows

connection to the customer’s control system via an integral 5-

pin M12 cable connector. These units have an integrated

alignment LED and permanent autocontrol – a feature not

usually found on Type 2 safety devices.

The new sensors take up much less space than the

mechanical guards they replaced, improving workplace

ergonomics. Loading and unloading is no longer impeded,

increasing productivity while actively safeguarding operators.

Safetinex Type 2 light curtains provide a reliable and cost-

effective solution.

TYPE 4 SAFETY LIGHT CURTAINS -

FINGER RESOLUTION (14MM)- BASIC

OR ADVANCED SOLUTIONS

PRODUCT ADVANTAGES - ‘BASIC’ LIGHT CURTAINS

HIGHEST PROTECTION CATEGORY: TYPE 4 - 14 MM (FINGER)

142MM TO 1,690MM PROTECTIVE HEIGHT

MAX. OPERATING RANGE 3.5M

OPERATING TEMPERATURE −35 … +60°C (−31 … +140°F)

STANDARD HOUSING (42 × 48 MM) IP65, IP67

2-CHANNEL SELECTION

OPTICAL SYNCHRONIZATION

PERMANENT AUTOCONTROL

If the risk assessment allows for their use, Type 2 Light Curtains

are a cost-effective choice for which Contrinex offers parts from

its BASIC (42 x 48mm), or BASIC SLIM (26 x 26mm) ranges.

For Type 4 requirements, light curtains are offered in the BASIC

(42 x 48mm) and EXTENDED SLIM (26 x 26mm) ranges..

The BASIC and BASIC SLIM range offers robust extruded

housing (42 x 48mm, or 26 x 26mm respectively) , TÜV, CE and

UL-certification according to IEC 61496-1 and -2 and ISO 13849-1.

They feature permanent autocontrol and low power

consumption with easy and low-cost installation provided by

their use of an integral 5-pin M12 connector or pigtail.

The EXTENDED SLIM range are all Type 4 light curtains which

are TÜV, CE and UL certified according to IEC 61496-1 and 2, IEC

61508-1/2/3 and ISO 13849-1. Protective heights range from 170

to 1610 mm with integrated EDM*, restart interlock and beam

coding. Since EDM includes a relay monitoring function, users

can also avoid the cost of wired relays.

The slim housing (26mm x 26mm) enables blind-zone free

installation and connection is via an integral 5-pin or 8-pin M12

pigtail.

Bluetooth(R) wirless connectivity for configured and monitoring

is offered using a free smartphone app – A world first!

PRODUCT ADVANTAGES - ‘ADVANCED SLIM’ CURTAINS

CATEGORY 4, PL E ACCORDING TO EN/ISO 13849-1

TYPE 4 ACCORDING TO IEC 61496-1 AND -2

RESOLUTION: 30 MM - CERTIFIED TÜV, CE

PROTECTIVE HEIGHT: 170 TO 1,610MM

OPERATING RANGE: 0.25 TO 5M

OPERATING TEMPERATURE −35 … +60°C (−31 … +140°F)

2-CHANNEL SELECTION - OPTICAL SYNCHRONIZATION

PERMANENT AUTOCONTROL - LOW POWER CONSUMPTION

STANDARD HOUSING (42 × 48MM) - IP65, IP67

SLIM HOUSING (26× 26MM) - IP65

CUSTOMER VALUES

MEETS HIGHEST SAFETY REQUIREMENTS ECONOMICALLY

RELIABLE AND ADAPTABLE

EASY TO INSTALL

FAIL-SAFE ELECTRONIC DESIGN

SECURES LOWER LIABILITY COSTS

PROTECTS EMPLOYEES AND ENVIRONMENT

REDUCES LOSS OF FLUIDS INVOLVED

PRODUCT ADVANTAGES

PERMANENT CERTIFIED CE, TÜV, AND UL

IP 65 AND IP 67 CLASS PROTECTION

CATEGORY 4, PL E ACCORDING TO EN/ISO 13849-1

TYPE 4 ACCORDING TO EN/IEC 61496-1 AND -2

RUGGED CONSTRUCTION

SOIL AND MIST TOLERANT

SIMPLE INSTALLATION

LONG DETECTION RANGE

A high pressure/high temperature degreasing tank line is used

to clean machined metal parts for the automotive industry. To

protect operators from possible injury while degreasing is in

progress, Safetinex YBB-30 safety light curtains have been

installed and connected to the machine control system.

CUSTOMER APPLICATION

The manufacture of automotive parts by stamping or

machining involves liberal use of oily lubricants. However,

these processes leave finished parts heavily laden with oily

residues that must be eliminated prior to assembly. A

degreasing tank line provides the necessary cleaning.

Degreasing tanks contain caustic fluids at high pressure

and/or high temperature, which effectively remove all traces of

lubricant and protective coatings. However, some aspects of

this process are potentially hazardous to both employees and

the environment. The high temperature and pressure at which

cleaning takes place means that anyone accessing the tank

while the process is running risks injury from caustic spray and

harmful vapours.

The containment method chosen must take account of the

need for human interventions, while ensuring operator safety.

Liability costs must be minimized and loss of process fluids

reduced. Electromechanical interlocks were considered, but a

simpler and more operator friendly solution was sought.

CUSTOMER SOLUTION

With their ease of installation and use, Safetinex YBB safety

light curtains were selected for this application. They meet

safety category 4 of EN ISO 13849-1 as well as type 4 of DIN EN

61496-1 and -2.

The safety light curtain comprises a sender and a receiver unit.

Infra-red beams generate a protective field between the two

units. LED displays on the sender and the receiver indicate

field status, operating mode, transmission channel, and

alignment quality. Reliability is guaranteed by a fail-safe

electronic design with permanent autocontrol.

Positioning a safety light curtain near the point of access to

the tank lids prevents the operator from opening them while

cleaning is in progress. The extent of the protective field also

ensures that no operator can access the hazardous area by

reaching over, under or around the light curtain. Any object

entering the protective field will not only disable the spray jets

and stop agitation, but will also cause the control system to

idle before allowing access.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS