(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

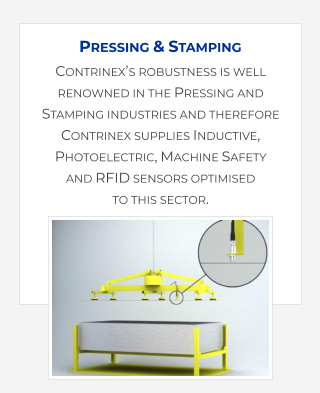

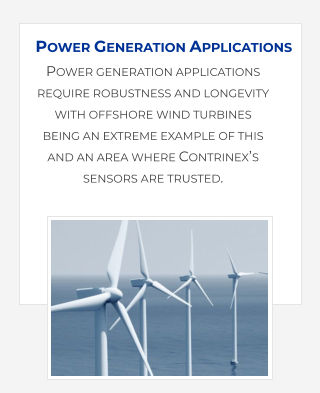

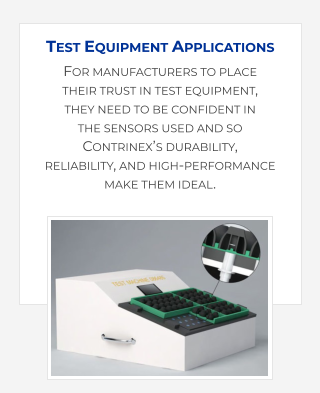

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

NO READJUSTMENT OVER TIME

NO WEAR AND TEAR AND RELATIVELY TAMPER-PROOF

LONG TERM RELIABILITY

NO MAINTENANCE

PRODUCT ADVANTAGES

EASY ADJUSTMENT/SETUP

LOCAL ANNUNCIATION (LED INDICATOR)

AFFORDABLE SENSOR WITH EXCELLENT RELIABILITY

A manufacturer of mobile cranes uses Contrinex 2-wire

inductive sensors to detect the position of stabiliser legs as

part of the vehicle safety system. Before the system will allow

the driver to drive the vehicle away, sensors confirm that

stabiliser legs have been retracted.

CUSTOMER APPLICATION

Mobile cranes, telescopic handlers and the like are equipped

with extendable stabiliser legs to prevent them from tipping

over when lifting. These stabiliser legs (or jacks) are

mechanical extensions of the chassis which widen the base of

the vehicle’s chassis to ensure its stability in all operating

situations. However, when the time comes to move the vehicle,

there must be verification that these stabilisers are fully

retracted. Either an indicator in the driver’s cab or a method of

disabling engagement of the vehicle’s transmission is used to

ensure safety and prevent drive-away accidents and damage.

The customer’s existing verification system relies on

mechanical contacts. However, the costs of maintenance and

replacements over the long lifetime of such vehicles are

relatively high and hence a non-contact solution was sought

.

Customer Solution

A normally closed, two-wire inductive sensor from Contrinex’s

Classic 600 Series was ideal for this application. Multiple

sensors (one for each stabiliser cylinder) are installed and

connected in a way that requires each sensor to be satisfied

that a target is either present or absent, thus completing a

logic circuit.

Initially, the simplest approach would seem to be to wire this

group of devices in series, as would be the case with

mechanical contacts. However, when using sensors, series

wiring presents the challenge of voltage drops. The customer

overcomes this by selecting 2-wire sensors with a ‘normally

closed’ output, then wiring them in parallel to create a logical

NAND situation.

This wiring solution resolves the issue and permits an easy to

implement, non-contact, non-mechanical approach to

providing feedback for the warning or inhibiting mechanism

of the vehicle.

PRODUCT ADVANTAGES

RANGE OF DC, AC AND NAMUR SENSORS

INCLUDES RANGE OF SIZES FROM Ø 3 TO M30

5 X 5 MM SQUARE-SECTION SENSOR AVAILABLE

EMBEDDABLE OR NON-EMBEDDABLE MOUNTING OPTIONS

CONNECTION BY MEANS OF CABLE OR CONNECTOR

SENSING RANGE UP TO 15 MM

ENSURE OPTIMAL EQUIPMENT UTILISATION

CONTRINEX’S 2-WIRE INDUCTIVE SENSORS INCLUDE DC, AC/DC AND NAMUR OPTIONS IN SIZES

FROM Ø3 TO M30, PLUS A 5 X 5MM SQUARE-SECTION AND A SENSING RANGE UP TO 15 MM.

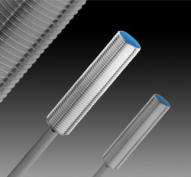

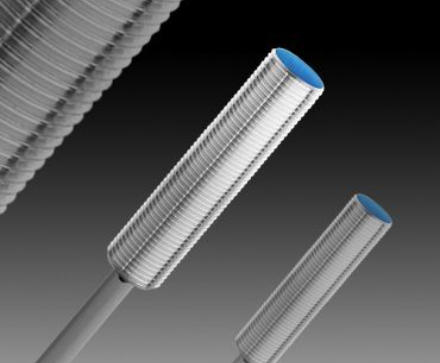

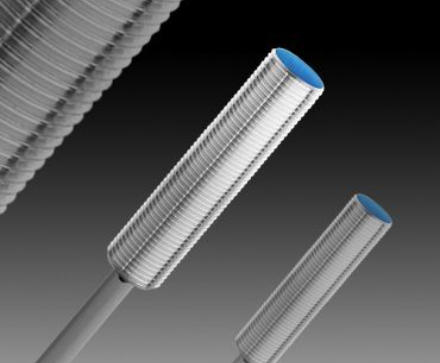

2-WIRE INDUCTIVE SENSORS

2-WIRE INDUCTIVE SENSORS - A GREAT REPLACEMENT FOR MECHANICAL BREAKERS

Contrinex’s 2-Wire Inductive sensors are available in DC, AC/DC and NAMUR versions, in sizes from Ø 3 to M30, plus a 5 x 5mm

square-section type. Devices are available for embeddable or non-embeddable mounting and connection is by means of cable or

connector. With a sensing range up to 15 mm, Contrinex 2-WIRE sensors ensure optimal equipment utilisation.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER VALUES

NO READJUSTMENT OVER TIME

NO WEAR AND TEAR AND RELATIVELY TAMPER-PROOF

LONG TERM RELIABILITY

NO MAINTENANCE

PRODUCT ADVANTAGES

EASY ADJUSTMENT/SETUP

LOCAL ANNUNCIATION (LED INDICATOR)

AFFORDABLE SENSOR WITH EXCELLENT RELIABILITY

A manufacturer of mobile cranes uses Contrinex 2-wire

inductive sensors to detect the position of stabiliser legs as

part of the vehicle safety system. Before the system will allow

the driver to drive the vehicle away, sensors confirm that

stabiliser legs have been retracted.

CUSTOMER APPLICATION

Mobile cranes, telescopic handlers and the like are equipped

with extendable stabiliser legs to prevent them from tipping

over when lifting. These stabiliser legs (or jacks) are

mechanical extensions of the chassis which widen the base of

the vehicle’s chassis to ensure its stability in all operating

situations. However, when the time comes to move the vehicle,

there must be verification that these stabilisers are fully

retracted. Either an indicator in the driver’s cab or a method of

disabling engagement of the vehicle’s transmission is used to

ensure safety and prevent drive-away accidents and damage.

The customer’s existing verification system relies on

mechanical contacts. However, the costs of maintenance and

replacements over the long lifetime of such vehicles are

relatively high and hence a non-contact solution was sought

.

Customer Solution

A normally closed, two-wire inductive sensor from Contrinex’s

Classic 600 Series was ideal for this application. Multiple

sensors (one for each stabiliser cylinder) are installed and

connected in a way that requires each sensor to be satisfied

that a target is either present or absent, thus completing a

logic circuit.

Initially, the simplest approach would seem to be to wire this

group of devices in series, as would be the case with

mechanical contacts. However, when using sensors, series

wiring presents the challenge of voltage drops. The customer

overcomes this by selecting 2-wire sensors with a ‘normally

closed’ output, then wiring them in parallel to create a logical

NAND situation.

This wiring solution resolves the issue and permits an easy to

implement, non-contact, non-mechanical approach to

providing feedback for the warning or inhibiting mechanism

of the vehicle.

CLICK ON AN IMAGE TO VIEW THE BROCHURE,

READ APLICATION EXAMPLES BELOW, CLICK

HERE TO VIEW THIS SENSOR ON CONTRINEX’S

WEBSITE, OR CALL US TO HELP GUIDE YOU

THROUGH SELECTION, ANSWER QUESTIONS, OR

TO HELP YOU #MAKESENSEOFSENSORS:

2-WIRE INDUCTIVE SENSORS

CONTRINEX’S 2-WIRE INDUCTIVE SENSORS INCLUDE

DC, AC/DC AND NAMUR OPTIONS IN SIZES FROM

Ø3 TO M30, PLUS A 5 X 5MM SQUARE-SECTION

AND A SENSING RANGE UP TO 15 MM.

PRODUCT ADVANTAGES

RANGE OF DC, AC AND NAMUR SENSORS

INCLUDES RANGE OF SIZES FROM Ø 3 TO M30

5 X 5 MM SQUARE-SECTION SENSOR AVAILABLE

EMBEDDABLE OR NON-EMBEDDABLE MOUNTING OPTIONS

CONNECTION BY MEANS OF CABLE OR CONNECTOR

SENSING RANGE UP TO 15 MM

ENSURE OPTIMAL EQUIPMENT UTILISATION

2-WIRE INDUCTIVE SENSORS - A GREAT

REPLACEMENT FOR MECHANICAL BREAKERS

Contrinex’s 2-Wire Inductive sensors are available in DC, AC/DC

and NAMUR versions, in sizes from Ø 3 to M30, plus a 5 x 5mm

square-section type. Devices are available for embeddable or

non-embeddable mounting and connection is by means of cable

or connector. With a sensing range up to 15 mm, Contrinex 2-

WIRE sensors ensure optimal equipment utilisation.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS