(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

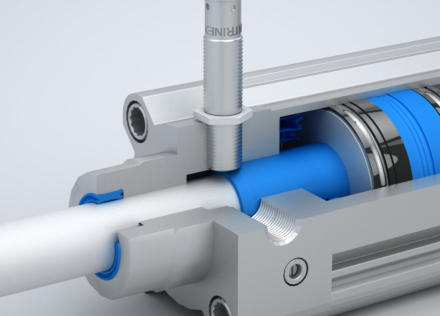

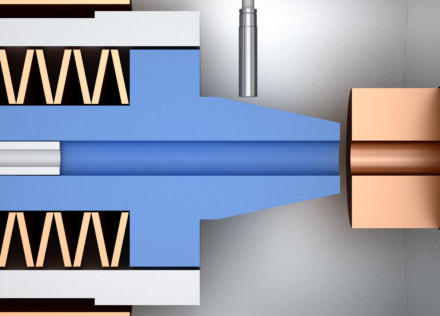

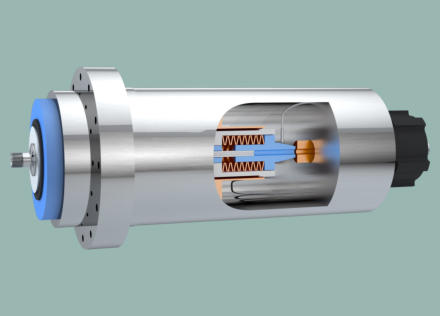

CNC machining centres use automatic tool-changing spindles

to rapidly switch between different tools with characteristic

suited to different materials, work-pieces and cutting speeds.

To ensure that a new tool engages completely in order to

prevent damage to the tool, the work-piece or the spindle,

designers specified Contrinex’s NEW SMART inductive sensors.

Embedded within the body of the spindle, the sensor monitors

the position of the tool during changes, so that any non-

compliant measurement stop the process, triggering an alarm.

CUSTOMER APPLICATION

Modern machine-tool spindles offer CNC machine designers

huge flexibility, enabling individual machining centres to cope

with ranges of materials, batch sizes, work-pieces, tools and

cutting speeds that might previously have needed several

different machines. Successive cuts often call for different tool

characteristics, spindles with automatic tool-changing are key

to optimizing throughput.

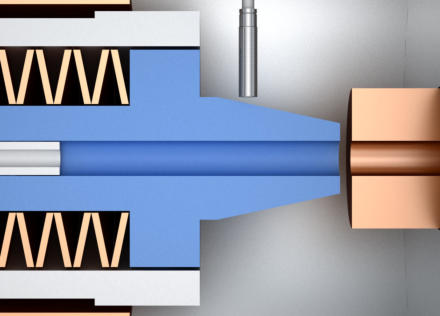

A spring-loaded collet, actuated by a central drawbar that runs

the length of the spindle, retains the tool in position. Once the

tool to be changed is moved to its designated position in the

machine’s tool-storage magazine, an actuator pushes the

drawbar forward along its axis until the collet disengages,

releasing the tool. The spindle then moves to the location of

the new tool in the magazine and the process is reversed.

From time to time, the collet may fail to retract fully,

preventing the new tool from engaging completely. Failing to

detect and rectify the problem leads to expensive damage to

the tool, the workpiece and possibly the spindle. Spindle

manufacturers require a robust, fail-safe method of detecting

incomplete tool engagement in what is already a tightly

packed assembly.

CUSTOMER SOLUTION

Designers specified rugged inductive sensors from the

Contrinex Smart Sensor portfolio; a single metal-cased sensor,

embedded radially in the body of the spindle immediately

adjacent to the rear of the drawbar, performs the required

tasks. All Contrinex Smart Sensors feature IO-Link connectivity,

providing a single, industry-standard interface to the machine

control system.

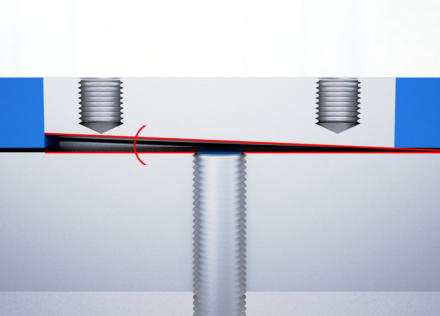

The sensor operates as a high-precision distance-

measurement device; its target is a longitudinally inclined face

on the circumference of the drawbar. As the drawbar moves

forward, the distance to the inclined faces changes in direct

proportion to the distance moved. With a sensing distance of

up to 6 mm and a dynamic resolution of ±5.5 micrometres, the

sensor delivers a highly accurate 16-bit digital output, enabling

the drawbar position to be determined in real time.

At the time of initial calibration, the drawbar positions

corresponding to the two extremes of travel are recorded in

the sensor’s local data store. Thereafter, the sensor operates in

two distinct modes: During tool changes, the drawbar position

is monitored in real time, ensuring that its motion follows the

expected pattern; once the extreme of travel is reached in

either direction, the sensor de-energizes the actuator and

initiates the next stage of the process. Any non-compliant

measurements stop the process and trigger an alarm.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. On-board data storage

holds cumulative operating data for user-specified purposes,

including predictive maintenance. These highly versatile

sensors meet designers’ needs for a reliable, cost-effective and

compact solution that delivers ultimate peace of mind.

CUSTOMER VALUES

EMBEDDABLE INDUCTIVE SMART SENSOR MONITORS

DRAWBAR POSITION, DETECTING INCOMPLETE TOOL

ENGAGEMENT AND INHIBITING FURTHER MOTION BEFORE

DAMAGE OCCURS

SINGLE-SENSOR POSITIONAL-CONTROL SYSTEM IS NON-

COMPLEX AND HIGHLY AFFORDABLE

EMBEDDABLE M12 SENSOR FITS SNUGLY IN THE LIMITED

SPACE AVAILABLE

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMIZED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION AND SERIAL

NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

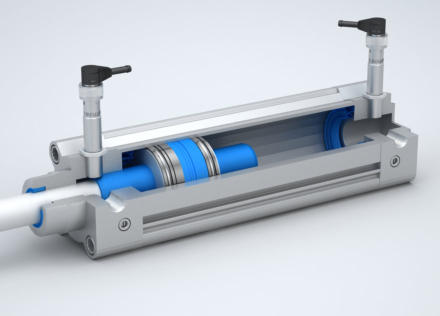

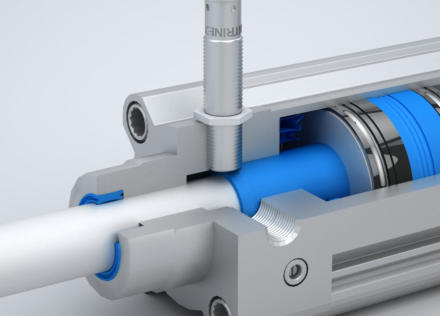

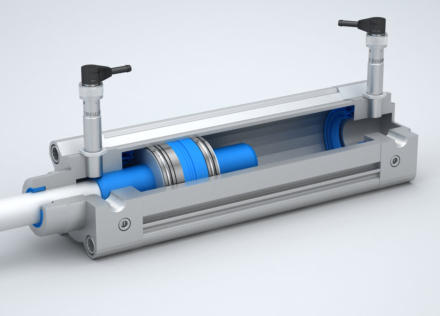

Contrinex SMART inductive sensors help industrial equipment

designers find new ways to reduce cycle times without

compromising safety or increasing cost. Automation engineers

designing a monitoring system for pneumatic cylinders need

to identify deviations from the optimal deceleration profile

without increasing complexity or cost. The rugged, multi-

mode Smart Sensors from Contrinex embedded into the

cylinder, identify adverse trends in the deceleration profile,

providing a cost-effective, unobtrusive fit-and-forget solution.

CUSTOMER APPLICATION

Industrial automation enables the optimisation of machine

performance, with equipment designers always looking for

ways to reduce cycle times without compromising safety at

little or ideally no increased cost. Pneumatic systems are a

typical challenge to engineers where they are commonly used

to move parts between workstations using an optimal

combination of cylinder size, travel speed and air

consumption.

The maximum piston travel speed for a given load is generally

known, but optimising the rate of acceleration and,

particularly, deceleration at each end of the travel brings

additional factors into play. Stopping too suddenly generates

high internal forces that may overload the cylinder, while

insufficient deceleration results in a sudden impact when the

load reaches the limit of the allowed travel.

Cushioning, where an internal damping mechanism is

designed into the cylinder, enables an optimum level of

deceleration to be achieved, but requires an application-

specific adjustment during commissioning. As a cylinder

wears during service, its set-up becomes suboptimal,

necessitating readjustment. Process engineers require a

monitoring capability that identifies deviations from the

specified deceleration profile; ideally, this should utilise

existing sensors to avoid increased complexity and cost.

CUSTOMER SOLUTION

The designers identified and specified a highly versatile, cost-

effective solution to the problem, namely Contrinex’s SMART

Sensors. The multiple sensing modes offered in a single

inductive sensor provide all the answers in a compact and

robust package, ideally suited to the demanding environment.

A sensor is embedded at each end of the cylinder to provide

high-resolution, real-time measurement of piston

displacement and also provide a cumulative data store that

allows process drift to be monitored. Designed with the needs

of OEMs and system integrators in mind, Smart Sensors

provide an unobtrusive fit-and-forget solution.

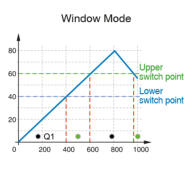

As the piston approaches the deceleration zone, engineers use

the Smart Sensor’s inbuilt one-shot timer feature to trigger a

rapid succession of displacement measurements. Taken at

known time intervals and recorded in the sensor’s data store,

these measurements provide a velocity gradient during the

deceleration phase that, plotted over multiple process cycles,

identifies deviations from the piston’s optimal deceleration

profile. Consequently, readjustment is scheduled only when

necessary, minimising maintenance costs.

Mounted immediately adjacent to the piston travel path, these

embeddable, metal-cased M12 Smart Sensors, which have a

nominal 6-mm sensing distance for carbon steel, are highly

robust and resistant to vibration and mechanical shock.

Capable of measuring both lateral and axial displacement

directly, these devices also offer process engineers the option

to monitor temperature, vibration and process cycle count.

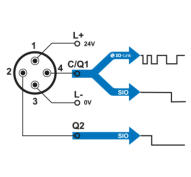

IO-Link connectivity, standard across the range, provides an

industry-standard interface to the machine control system; the

Smart Sensor’s dual-channel capability also enables a local

alarm to be triggered by an event-based exception, for

example, over-temperature or excessive piston travel. During

initial calibration, each sensor’s configuration is stored

automatically on the local IO-Link Master; this allows plug-and-

play replacement of sensors should the need arise, without

any loss of functionality and without any need for recalibration.

CUSTOMER VALUES

MULTIPLE SENSING MODES IN A SINGLE EMBEDDABLE DEVICE,

ELIMINATING INCREASED COMPLEXITY AND COST.

ONE-SHOT TIMER FEATURE ALLOWS PROCESS ENGINEERS TO

IDENTIFY DEVIATIONS FROM THE OPTIMAL DECELERATION

PROFILE, MINIMISING MAINTENANCE EXPENSE.

DUAL-CHANNEL CAPABILITY ENABLES A LOCAL ALARM TO BE

TRIGGERED BY AN EVENT-BASED EXCEPTION, AVOIDING A

PLANT-WIDE SHUT-DOWN.

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM.

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE.

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED.

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALISED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION & SERIAL NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

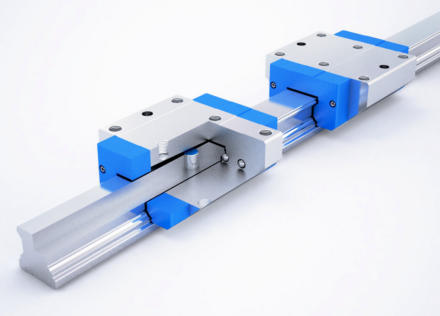

Contrinex inductive sensors help automation companies build

high-speed assembly equipment and their new SMART

Inductive sensors can help by being able to measure, monitor,

configure and help predict.

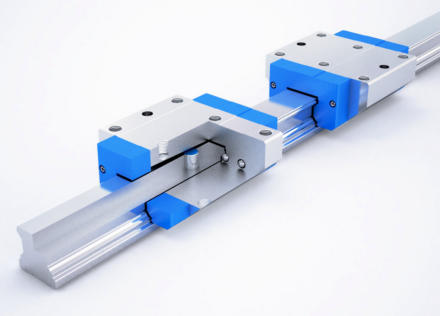

High-speed automated systems frequently use linear transfers

stages between workstations to maximise speed and accuracy

while keeping cost down. Designers of these linear transfer

units required a single-sensor positional-control solution that

controls both high-speed movements as the slide approaches

the critical area, where it slows down and also to provide high-

precision final positioning.

To achieve this, Contrinex’s inductive SMART Sensors were

selected. A single smart sensor with IO-Link connectivity and

multiple user-configurable outputs performs both the

required tasks in a highly cost-effective manner.

CUSTOMER APPLICATION

Automation engineers often face a three-way balancing act

when designing equipment, trying to maximise speed and

accuracy while keeping cost at acceptable levels. Position

control is no exception – high-performance systems typically

rely on linear or rotary encoders to deliver the required

positional accuracy, and these can be expensive, particularly

when both coarse and fine positioning is needed.

Using a secondary sensor for coarse-positional control is a

commonly used, although inelegant, solution to the problem.

It also increases complexity and cost, while reducing the

overall reliability of the system. Alternatively, designers

maintain accuracy without increasing cost by reducing travel

speeds during coarse positioning, increasing the cycle time.

Neither approach is optimal.

Equipment manufacturers (OEMs) specifying high-speed

assembly equipment with multiple linear transfers between

workstations need an alternative solution. Using off-the-shelf

linear stages, they require a controlled, fast approach to the

critical areas and a slower, high-precision final positioning –

without increasing complexity or cost. An affordable single-

sensor solution is highly desirable.

CUSTOMER SOLUTION

The designers specified rugged inductive sensors from the

Contrinex SMART Sensor portfolio; a single sensor with IO-Link

connectivity and multiple user-configurable outputs performs

both the required tasks. Firstly, it initiates a controlled

deceleration as the carriage of a linear stage approaches the

specified workstation; it then switches to micrometer distance

resolution, positioning the stage accurately and precisely.

Contrinex inductive SMART Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. A single metal-cased M12

sensor is embedded in one of the guide rails immediately

adjacent to each workstation. The sensor detects the presence

of the carriage as it begins to pass overhead, triggering the

deceleration and changing the sensing mode.

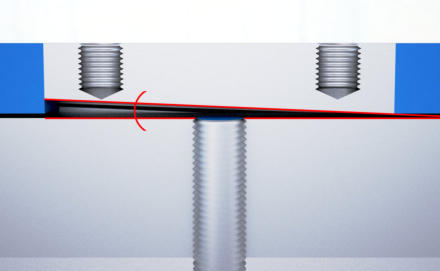

The sensor now operates as a high-precision distance-

measurement device; its target is an inclined face on the

underside of the carriage. As the carriage moves over the

sensor, the distance to the inclined faces changes in direct

proportion to the distance moved. With a sensing distance of

up to 6mm and a dynamic resolution of ±5.5 micrometres, the

sensor delivers a highly accurate 16-bit digital output, enabling

the carriage position to be determined in real-time.

Once the initial set-up is completed, each sensor’s

configuration is stored automatically on the local IO-Link

Master; this allows plug-and-play replacement of sensors

should the need arise, without any loss of functionality and

without any need for recalibration. These highly versatile

sensors meet designers’ needs for a highly reliable, cost-

effective and non-complex solution without compromising

operational performance.

CUSTOMER VALUES

EMBEDDABLE SENSOR PROVIDE ACCURATE POSITIONING OF

LINEAR STAGES AND MAINTAIN OPERATIONAL SPEED

SINGLE-SENSOR POSITIONAL-CONTROL SYSTEM IS NON-

COMPLEX AND HIGHLY AFFORDABLE

COMPACT EMBEDDABLE M12 SENSORS FIT UNOBTRUSIVELY

AND EASILY INTO OFF-THE-SHELF LINEAR GUIDE RAILS

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM.

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED.

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ON-BOARD DATA STORAGE HOLDS CUMULATIVE OPERATING

DATA FOR USER-SPECIFIED PURPOSES, INCLUDING PREDICTIVE

MAINTENANCE

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION AND SERIAL

NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

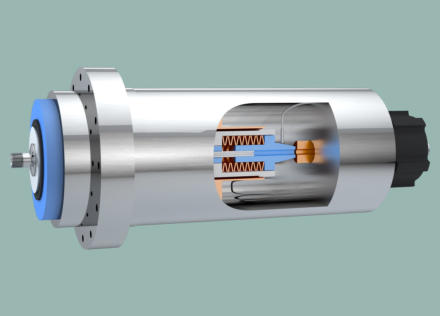

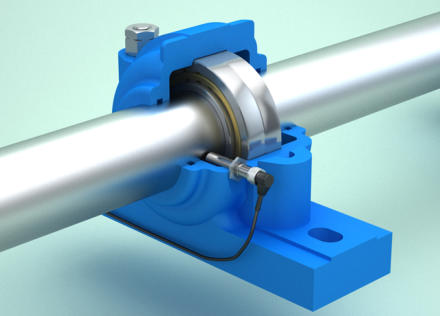

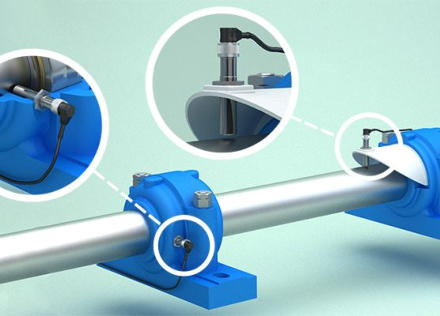

Contrinex Smart Sensors are utilised in condition-based

monitoring of critical rotating machinery. They monitor

multiple parameters in real-time, including unexpected levels

of vibration, increased bearing temperature or irregular radial

deflections of a shaft. These highly versatile sensors provide a

flexible, cost-effective solution that maximizes data availability

without adding complexity.

CUSTOMER APPLICATION

Engineers are always seeking ways to minimise machine

downtime without risking costly breakdowns. It is a dilemma

faced by engineers and designers worldwide, especially in

sectors like heavy industry, mining, marine engineering, oil

and gas, green energy and rail operations where rotating

machinery is common-place and the machinery is often

remotely located or inaccessible.

Bearing failure is a significant risk in equipment with rotating

elements and it is generally sign-posted in its early stages by

increased levels of vibration and a rise in bearing temperature.

Typically, this risk is managed by frequent inspection and

maintenance of bearings, but condition-based monitoring

(CBM) has become the preferred approach for cost-effective

maintenance operations. CBM uses sensor technology to

extract real-time data from machinery, developing a

performance profile that identifies potential failures before

they bring operations to a ‘grinding halt’.

Designers have to balance the desire to collect as much data

as possible, on vibration, deflection, temperature and

operating hours, which might all help predict an imminent

breakdown, while keeping cost and complexity to a minimum.

Specifying multiple sensors meets the data-collection needs,

but is a costly approach, often requiring significant

compromise in mechanical design.

CUSTOMER SOLUTION

Contrinex Multi-Mode Smart Sensors fulfil the application’s

requirements without compromise, using their multi-function

technology. A single Smart Sensor can monitor multiple

parameters including deflection, vibration, temperature, linear

position, angular displacement and cycle count. Each of these

measurements may be reported as process data or event data,

while cumulative operating parameters are recorded in the

sensor’s on-board storage.

The user-defined operating modes enable a single sensor to

provide a range of functions. On the rotating machinery, it is

mounted in either a bearing housing or adjacent to a shaft, to

monitor for unexpected levels of vibration, increased bearing

temperature or irregular radial deflections of the shaft.

The sensor’s IO-Link functionality provides plug-and-play

replacement of damaged sensors, without any loss of

functionality and without any need for configuration.

Dual-channel operation is another valuable feature of the

Smart Sensor range. Should a critical event occur, the sensor

delivers a high-speed notification directly to the control

system, bypassing the IO-Link communications channel and

initiating a shut-down sequence immediately. This avoids

further, costly damage and minimizes subsequent process

downtime.

Smart Sensors are exceptionally reliable, making them ideal for

installation in remote locations where day-to-day access can

be impossible. In wind turbines, rail cars, drag-lines, marine

powerplants, paper mills, drilling platforms, construction

equipment, heavy-duty pumps and a host of similar

installations, these highly versatile sensors tick all the boxes.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and System Integrators in mind to provide an

unobtrusive fit-and-forget solution. For flexible, cost-effective

CBM solutions that maximize data availability without adding

complexity, Contrinex Multi-Mode Smart Sensors deliver

complete peace of mind.

CUSTOMER VALUES

ROBUST, METAL-CASED SMART SENSORS ARE IDEAL FOR EASY

INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE CUSTOMIZED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER HIGH-

PRECISION ANALOG OUTPUT SIGNALS

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE 5 CUSTOMISED OUTPUT THRESHOLDS

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION & SERIAL NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

PRODUCT ADVANTAGES

SENSORS COMPATIBLE WITH INDUSTRY-STANDARD SMART

SENSOR PROFILE: IO-LINK SSP 3.3, DIGITAL MEASURING

SENSORS (DMS) WITH DISABLE FUNCTION

CLOUD-READY SENSORS WITH PERFORMANCE EQUIVALENT

TO A CONVENTIONAL ANALOG OUTPUT SENSOR, BUT WITH A

DIGITAL DATA OUTPUT

32-BIT PROCESS DATA INPUT (PDI) WITH 16-BIT VALUES FOR

DISTANCE, COUNTER AND TEMPERATURE, 8-BIT VALUES FOR

MEASUREMENT DATA SCALING AND 8-BIT VALUES FOR OUTPUT

SWITCHING SIGNAL, SWITCHING SIGNAL AND CONFIGURABLE

ALARM FLAGS. THE 8-BIT PROCESS DATA OUTPUT (PDO)

INCLUDES A DISABLE FUNCTION.

USER-DEFINABLE IO-LINK PARAMETERS: DISTANCE,

COUNTER, TEMPERATURE AND SWITCH-POINT MODE

(DEACTIVATED, SINGLE POINT, WINDOW MODE, TWO-POINT

MODE)

PRE-DEFINED PREDICTIVE MAINTENANCE FUNCTIONS:

OPERATING HOURS SINCE FIRST/LAST POWER-UP, SWITCHING

COUNTER SINCE FIRST/LAST POWER-UP, SENSOR AUTO-

DIAGNOSTIC ALARM

CONTRINEX’S NEW CLOUD-READY SMART SENSORS ARE PERFECT FOR LIVE DATA

MONITORING FROM THE HEART OF AN APPLICATION WITH FAST AND SIMPLE SET-UP.

SMART INDUCTIVE SENSORS

Contrinex’s new cloud-ready Smart Sensors are perfect for live data monitoring from the heart of an application. Simply by

configuring an IO-Link parameter, the user can output and display sensor data in real time on any cloud dashboard.

The Smart Sensors which were designed with the needs of OEMs and system integrators in mind, have all the answers when it

comes to reducing complexity and cost. By implementing multiple sensing modes in a single sensor, Contrinex has given

designers the freedom they’ve always dreamed about, offering exceptional versatility and simplified integration.

Let Contrinex Smart Sensors supercharge your IoT strategy; enjoy all the advantages of the industry-standard IO-Link SSP 3.3

interface, plus the option of high-speed sensor-based decision-making using SIO. The only limit is your imagination….

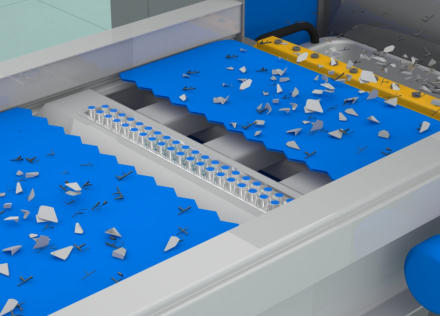

The recycling industry utilises automation to reduce the cost of

sorting and separating mixed-metal scrap. One such solution

is automated sorting, which requires sensors which both

operate accurately and at high speed to identify and separate

fast-moving streams of ferrous and non-ferrous material in a

single pass. Rugged inductive Smart Sensors from Contrinex,

are embedded immediately below the delivery belt to provide

continuous high-speed detection across the full width of a

conveyor belt.

CUSTOMER APPLICATION

The global recycling industry relies upon advances in

technology to automate waste-recovery operations. These

make it economic to recover an ever greater proportion of

domestic and industrial waste. Waste-management

companies are always looking for more affordable alternatives

for sorting and separating mixed-metal scrap as some of the

existing processes, while effective, are inflexible and expensive.

Advances in sensor technology and capabilities have seen the

introduction of induction sorting, a process that identifies and

separates different types of metallic material. A fast-moving

conveyor carries pre-sized waste over a bank of inductive

sensors mounted below the belt; the sensors detect and

identify any non-ferrous material, which is subsequently

ejected and separated by a targeted air-knife.

To take full advantage of the process, OEM equipment builders

require robust sensors that differentiate accurately and at high

speed between ferrous and non-ferrous material, allowing a

single bank of sensors to process mixed-metal waste in a

single pass. As the sensors may operate independently or in

combination with other sensing technologies, an industry-

standard communication interface is highly desirable.

CUSTOMER SOLUTION

Designers specified rugged inductive sensors from the

Contrinex Smart Sensor portfolio; an array of 50 metal-cased

sensors, embedded in a grid pattern immediately below the

belt, provides continuous detection across the full width of the

conveyor. Best-practice electronic design ensures that Smart

Sensors are individually shielded and EMC immune,

eliminating interference when multiple devices operate in

close proximity.

Mounted only a few millimetres from the target as it passes

overhead, these M18 devices, which have a nominal sensing

distance of 10 mm for carbon steel, generate analogue output

signals that vary according to the material type. The Smart

Sensors are easily able to accommodate the required range of

conveyor speeds.

IO-Link connectivity, standard across the range, provides an

industry-standard interface to the machine control system,

triggering the appropriate air-knives as pieces of non-ferrous

material reach the separator. During initial calibration, each

sensor’s configuration is stored automatically on the local IO-

Link Master; this allows plug-and-play replacement of sensors

should the need arise, without any loss of functionality and

without any need for recalibration.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. On-board data storage

holds cumulative operating data for user-specified purposes,

including predictive maintenance. These highly versatile

sensors meet designers’ needs for a robust and cost-effective

solution that delivers exceptional accuracy and reliability in a

particularly challenging environment.

CUSTOMER VALUES

HIGHLY ACCURATE, REPEATABLE SENSING PERFORMANCE IN

EMBEDDABLE INDUCTIVE SMART SENSORS DIFFERENTIATE

CLEARLY BETWEEN TARGET MATERIAL TYPES, DETECTING

NON-FERROUS METAL AND TRIGGERING SEPARATION

ACCURATELY AND RELIABLY

A SINGLE ARRAY OF SENSORS PROVIDES CONTINUOUS

DETECTION ACROSS THE FULL WIDTH OF A CONVEYOR

SMART SENSORS EASILY ABLE TO IDENTIFY MATERIAL ON

FAST-MOVING CONVEYORS THANKS TO HIGH SENSING SPEED

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER HIGH-

PRECISION ANALOGUE OUTPUT SIGNALS

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALISED DATA-PROCESSING AND DECISION MAKING

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION & SERIAL NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CNC machining centres use automatic tool-changing spindles

to rapidly switch between different tools with characteristic

suited to different materials, work-pieces and cutting speeds.

To ensure that a new tool engages completely in order to

prevent damage to the tool, the work-piece or the spindle,

designers specified Contrinex’s NEW SMART inductive sensors.

Embedded within the body of the spindle, the sensor monitors

the position of the tool during changes, so that any non-

compliant measurement stop the process, triggering an alarm.

CUSTOMER APPLICATION

Modern machine-tool spindles offer CNC machine designers

huge flexibility, enabling individual machining centres to cope

with ranges of materials, batch sizes, work-pieces, tools and

cutting speeds that might previously have needed several

different machines. Successive cuts often call for different tool

characteristics, spindles with automatic tool-changing are key

to optimizing throughput.

A spring-loaded collet, actuated by a central drawbar that runs

the length of the spindle, retains the tool in position. Once the

tool to be changed is moved to its designated position in the

machine’s tool-storage magazine, an actuator pushes the

drawbar forward along its axis until the collet disengages,

releasing the tool. The spindle then moves to the location of

the new tool in the magazine and the process is reversed.

From time to time, the collet may fail to retract fully,

preventing the new tool from engaging completely. Failing to

detect and rectify the problem leads to expensive damage to

the tool, the workpiece and possibly the spindle. Spindle

manufacturers require a robust, fail-safe method of detecting

incomplete tool engagement in what is already a tightly

packed assembly.

CUSTOMER SOLUTION

Designers specified rugged inductive sensors from the

Contrinex Smart Sensor portfolio; a single metal-cased sensor,

embedded radially in the body of the spindle immediately

adjacent to the rear of the drawbar, performs the required

tasks. All Contrinex Smart Sensors feature IO-Link connectivity,

providing a single, industry-standard interface to the machine

control system.

The sensor operates as a high-precision distance-

measurement device; its target is a longitudinally inclined face

on the circumference of the drawbar. As the drawbar moves

forward, the distance to the inclined faces changes in direct

proportion to the distance moved. With a sensing distance of

up to 6 mm and a dynamic resolution of ±5.5 micrometres, the

sensor delivers a highly accurate 16-bit digital output, enabling

the drawbar position to be determined in real time.

At the time of initial calibration, the drawbar positions

corresponding to the two extremes of travel are recorded in

the sensor’s local data store. Thereafter, the sensor operates in

two distinct modes: During tool changes, the drawbar position

is monitored in real time, ensuring that its motion follows the

expected pattern; once the extreme of travel is reached in

either direction, the sensor de-energizes the actuator and

initiates the next stage of the process. Any non-compliant

measurements stop the process and trigger an alarm.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. On-board data storage

holds cumulative operating data for user-specified purposes,

including predictive maintenance. These highly versatile

sensors meet designers’ needs for a reliable, cost-effective and

compact solution that delivers ultimate peace of mind.

CUSTOMER VALUES

EMBEDDABLE INDUCTIVE SMART SENSOR MONITORS

DRAWBAR POSITION, DETECTING INCOMPLETE TOOL

ENGAGEMENT AND INHIBITING FURTHER MOTION BEFORE

DAMAGE OCCURS

SINGLE-SENSOR POSITIONAL-CONTROL SYSTEM IS NON-

COMPLEX AND HIGHLY AFFORDABLE

EMBEDDABLE M12 SENSOR FITS SNUGLY IN THE LIMITED

SPACE AVAILABLE

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMIZED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION AND SERIAL

NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

Contrinex inductive sensors help automation companies build

high-speed assembly equipment and their new SMART

Inductive sensors can help by being able to measure, monitor,

configure and help predict.

High-speed automated systems frequently use linear transfers

stages between workstations to maximise speed and accuracy

while keeping cost down. Designers of these linear transfer

units required a single-sensor positional-control solution that

controls both high-speed movements as the slide approaches

the critical area, where it slows down and also to provide high-

precision final positioning.

To achieve this, Contrinex’s inductive SMART Sensors were

selected. A single smart sensor with IO-Link connectivity and

multiple user-configurable outputs performs both the

required tasks in a highly cost-effective manner.

CUSTOMER APPLICATION

Automation engineers often face a three-way balancing act

when designing equipment, trying to maximise speed and

accuracy while keeping cost at acceptable levels. Position

control is no exception – high-performance systems typically

rely on linear or rotary encoders to deliver the required

positional accuracy, and these can be expensive, particularly

when both coarse and fine positioning is needed.

Using a secondary sensor for coarse-positional control is a

commonly used, although inelegant, solution to the problem.

It also increases complexity and cost, while reducing the

overall reliability of the system. Alternatively, designers

maintain accuracy without increasing cost by reducing travel

speeds during coarse positioning, increasing the cycle time.

Neither approach is optimal.

Equipment manufacturers (OEMs) specifying high-speed

assembly equipment with multiple linear transfers between

workstations need an alternative solution. Using off-the-shelf

linear stages, they require a controlled, fast approach to the

critical areas and a slower, high-precision final positioning –

without increasing complexity or cost. An affordable single-

sensor solution is highly desirable.

CUSTOMER SOLUTION

The designers specified rugged inductive sensors from the

Contrinex SMART Sensor portfolio; a single sensor with IO-Link

connectivity and multiple user-configurable outputs performs

both the required tasks. Firstly, it initiates a controlled

deceleration as the carriage of a linear stage approaches the

specified workstation; it then switches to micrometer distance

resolution, positioning the stage accurately and precisely.

Contrinex inductive SMART Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. A single metal-cased M12

sensor is embedded in one of the guide rails immediately

adjacent to each workstation. The sensor detects the presence

of the carriage as it begins to pass overhead, triggering the

deceleration and changing the sensing mode.

The sensor now operates as a high-precision distance-

measurement device; its target is an inclined face on the

underside of the carriage. As the carriage moves over the

sensor, the distance to the inclined faces changes in direct

proportion to the distance moved. With a sensing distance of

up to 6mm and a dynamic resolution of ±5.5 micrometres, the

sensor delivers a highly accurate 16-bit digital output, enabling

the carriage position to be determined in real-time.

Once the initial set-up is completed, each sensor’s

configuration is stored automatically on the local IO-Link

Master; this allows plug-and-play replacement of sensors

should the need arise, without any loss of functionality and

without any need for recalibration. These highly versatile

sensors meet designers’ needs for a highly reliable, cost-

effective and non-complex solution without compromising

operational performance.

CUSTOMER VALUES

EMBEDDABLE INDUCTIVE SMART SENSOR ENSURE ACCURATE

POSITIONING OF LINEAR STAGES WITHOUT COMPROMISING

OPERATIONAL SPEED

SINGLE-SENSOR POSITIONAL-CONTROL SYSTEM IS NON-

COMPLEX AND HIGHLY AFFORDABLE

COMPACT EMBEDDABLE M12 SENSORS FIT UNOBTRUSIVELY

AND EASILY INTO OFF-THE-SHELF LINEAR GUIDE RAILS

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM.

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED.

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ON-BOARD DATA STORAGE HOLDS CUMULATIVE OPERATING

DATA FOR USER-SPECIFIED PURPOSES, INCLUDING PREDICTIVE

MAINTENANCE

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION AND SERIAL

NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

Contrinex SMART inductive sensors help industrial equipment

designers find new ways to reduce cycle times without

compromising safety or increasing cost. Automation engineers

designing a monitoring system for pneumatic cylinders need

to identify deviations from the optimal deceleration profile

without increasing complexity or cost. The rugged, multi-

mode Smart Sensors from Contrinex embedded into the

cylinder, identify adverse trends in the deceleration profile,

providing a cost-effective, unobtrusive fit-and-forget solution.

CUSTOMER APPLICATION

Industrial automation enables the optimisation of machine

performance, with equipment designers always looking for

ways to reduce cycle times without compromising safety at

little or ideally no increased cost. Pneumatic systems are a

typical challenge to engineers where they are commonly used

to move parts between workstations using an optimal

combination of cylinder size, travel speed and air

consumption.

The maximum piston travel speed for a given load is generally

known, but optimising the rate of acceleration and,

particularly, deceleration at each end of the travel brings

additional factors into play. Stopping too suddenly generates

high internal forces that may overload the cylinder, while

insufficient deceleration results in a sudden impact when the

load reaches the limit of the allowed travel.

Cushioning, where an internal damping mechanism is

designed into the cylinder, enables an optimum level of

deceleration to be achieved, but requires an application-

specific adjustment during commissioning. As a cylinder

wears during service, its set-up becomes suboptimal,

necessitating readjustment. Process engineers require a

monitoring capability that identifies deviations from the

specified deceleration profile; ideally, this should utilise

existing sensors to avoid increased complexity and cost.

CUSTOMER SOLUTION

The designers identified and specified a highly versatile, cost-

effective solution to the problem, namely Contrinex’s SMART

Sensors. The multiple sensing modes offered in a single

inductive sensor provide all the answers in a compact and

robust package, ideally suited to the demanding environment.

A sensor is embedded at each end of the cylinder to provide

high-resolution, real-time measurement of piston

displacement and also provide a cumulative data store that

allows process drift to be monitored. Designed with the needs

of OEMs and system integrators in mind, Smart Sensors

provide an unobtrusive fit-and-forget solution.

As the piston approaches the deceleration zone, engineers use

the Smart Sensor’s inbuilt one-shot timer feature to trigger a

rapid succession of displacement measurements. Taken at

known time intervals and recorded in the sensor’s data store,

these measurements provide a velocity gradient during the

deceleration phase that, plotted over multiple process cycles,

identifies deviations from the piston’s optimal deceleration

profile. Consequently, readjustment is scheduled only when

necessary, minimising maintenance costs.

Mounted immediately adjacent to the piston travel path, these

embeddable, metal-cased M12 Smart Sensors, which have a

nominal 6-mm sensing distance for carbon steel, are highly

robust and resistant to vibration and mechanical shock.

Capable of measuring both lateral and axial displacement

directly, these devices also offer process engineers the option

to monitor temperature, vibration and process cycle count.

IO-Link connectivity, standard across the range, provides an

industry-standard interface to the machine control system; the

Smart Sensor’s dual-channel capability also enables a local

alarm to be triggered by an event-based exception, for

example, over-temperature or excessive piston travel. During

initial calibration, each sensor’s configuration is stored

automatically on the local IO-Link Master; this allows plug-and-

play replacement of sensors should the need arise, without

any loss of functionality and without any need for recalibration.

CUSTOMER VALUES

MULTIPLE SENSING MODES IN A SINGLE EMBEDDABLE DEVICE,

ELIMINATING INCREASED COMPLEXITY AND COST.

ONE-SHOT TIMER FEATURE ALLOWS PROCESS ENGINEERS TO

IDENTIFY DEVIATIONS FROM THE OPTIMAL DECELERATION

PROFILE, MINIMISING MAINTENANCE EXPENSE.

DUAL-CHANNEL CAPABILITY ENABLES A LOCAL ALARM TO BE

TRIGGERED BY AN EVENT-BASED EXCEPTION, AVOIDING A

PLANT-WIDE SHUT-DOWN.

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM.

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE.

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED.

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE UP TO 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER DYNAMIC

LINEAR-DISTANCE MEASUREMENTS WITH A RESOLUTION IN

THE MICRON RANGE

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION AND SERIAL

NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

Contrinex Smart Sensors are utilised in condition-based

monitoring of critical rotating machinery. They monitor

multiple parameters in real-time, including unexpected levels

of vibration, increased bearing temperature or irregular radial

deflections of a shaft. These highly versatile sensors provide a

flexible, cost-effective solution that maximizes data availability

without adding complexity.

CUSTOMER APPLICATION

Engineers are always seeking ways to minimise machine

downtime without risking costly breakdowns. It is a dilemma

faced by engineers and designers worldwide, especially in

sectors like heavy industry, mining, marine engineering, oil

and gas, green energy and rail operations where rotating

machinery is common-place and the machinery is often

remotely located or inaccessible.

Bearing failure is a significant risk in equipment with rotating

elements and it is generally sign-posted in its early stages by

increased levels of vibration and a rise in bearing temperature.

Typically, this risk is managed by frequent inspection and

maintenance of bearings, but condition-based monitoring

(CBM) has become the preferred approach for cost-effective

maintenance operations. CBM uses sensor technology to

extract real-time data from machinery, developing a

performance profile that identifies potential failures before

they bring operations to a ‘grinding halt’.

Designers have to balance the desire to collect as much data

as possible, on vibration, deflection, temperature and

operating hours, which might all help predict an imminent

breakdown, while keeping cost and complexity to a minimum.

Specifying multiple sensors meets the data-collection needs,

but is a costly approach, often requiring significant

compromise in mechanical design.

CUSTOMER SOLUTION

Contrinex Multi-Mode Smart Sensors fulfil the application’s

requirements without compromise, using their multi-function

technology. A single Smart Sensor can monitor multiple

parameters including deflection, vibration, temperature, linear

position, angular displacement and cycle count. Each of these

measurements may be reported as process data or event data,

while cumulative operating parameters are recorded in the

sensor’s on-board storage.

The user-defined operating modes enable a single sensor to

provide a range of functions. On the rotating machinery, it is

mounted in either a bearing housing or adjacent to a shaft, to

monitor for unexpected levels of vibration, increased bearing

temperature or irregular radial deflections of the shaft.

The sensor’s IO-Link functionality provides plug-and-play

replacement of damaged sensors, without any loss of

functionality and without any need for configuration.

Dual-channel operation is another valuable feature of the

Smart Sensor range. Should a critical event occur, the sensor

delivers a high-speed notification directly to the control

system, bypassing the IO-Link communications channel and

initiating a shut-down sequence immediately. This avoids

further, costly damage and minimizes subsequent process

downtime.

Smart Sensors are exceptionally reliable, making them ideal for

installation in remote locations where day-to-day access can

be impossible. In wind turbines, rail cars, drag-lines, marine

powerplants, paper mills, drilling platforms, construction

equipment, heavy-duty pumps and a host of similar

installations, these highly versatile sensors tick all the boxes.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and System Integrators in mind to provide an

unobtrusive fit-and-forget solution. For flexible, cost-effective

CBM solutions that maximize data availability without adding

complexity, Contrinex Multi-Mode Smart Sensors deliver

complete peace of mind.

CUSTOMER VALUES

ROBUST, METAL-CASED SMART SENSORS ARE IDEAL FOR EASY

INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE CUSTOMIZED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER HIGH-

PRECISION ANALOG OUTPUT SIGNALS

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALIZED DATA-PROCESSING AND DECISION MAKING

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE 5 CUSTOMISED OUTPUT THRESHOLDS

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION & SERIAL NUMBER

VISIBLE LED INDICATORS ENABLE SENSORS TO SELF-IDENTIFY

ON DEMAND, SIMPLIFYING COMMISSIONING AND TROUBLE-

SHOOTING ROUTINES

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP

GUIDE YOU THROUGH SELECTION, ANSWER

QUESTIONS, OR TO HELP YOU

#MAKESENSEOFSENSORS:

SMART INDUCTIVE SENSORS

CONTRINEX’S NEW CLOUD-READY SMART

SENSORS ARE PERFECT FOR LIVE DATA

MONITORING FROM THE HEART OF AN

APPLICATION WITH FAST AND SIMPLE SET-UP.

PRODUCT ADVANTAGES

SENSORS COMPATIBLE WITH INDUSTRY-STANDARD SMART

SENSOR PROFILE: IO-LINK SSP 3.3, DIGITAL MEASURING

SENSORS (DMS) WITH DISABLE FUNCTION

CLOUD-READY SENSORS WITH PERFORMANCE EQUIVALENT

TO A CONVENTIONAL ANALOG OUTPUT SENSOR, BUT WITH A

DIGITAL DATA OUTPUT

32-BIT PROCESS DATA INPUT (PDI) WITH 16-BIT VALUES FOR

DISTANCE, COUNTER AND TEMPERATURE, 8-BIT VALUES FOR

MEASUREMENT DATA SCALING AND 8-BIT VALUES FOR OUTPUT

SWITCHING SIGNAL, SWITCHING SIGNAL AND CONFIGURABLE

ALARM FLAGS. THE 8-BIT PROCESS DATA OUTPUT (PDO)

INCLUDES A DISABLE FUNCTION.

USER-DEFINABLE IO-LINK PARAMETERS: DISTANCE,

COUNTER, TEMPERATURE AND SWITCH-POINT MODE

(DEACTIVATED, SINGLE POINT, WINDOW MODE, TWO-POINT

MODE)

PRE-DEFINED PREDICTIVE MAINTENANCE FUNCTIONS:

OPERATING HOURS SINCE FIRST/LAST POWER-UP, SWITCHING

COUNTER SINCE FIRST/LAST POWER-UP, SENSOR AUTO-

DIAGNOSTIC ALARM

SMART INDUCTIVE SENSORS - CLOUD-READY

SMART SENSORS WITH FAST & SIMPLE SET-UP

Contrinex’s new cloud-ready Smart Sensors are perfect for live

data monitoring from the heart of an application. Simply by

configuring an IO-Link parameter, the user can output and

display sensor data in real time on any cloud dashboard.

Predictive maintenance features are available to help speed up

troubleshooting, reduce machine downtime and save cost. These

new smart sensors can be integrated into an enterprise resource

planning (ERP) or manufacturing execution system (MES).

Setup is fast and simple, as all data structures are compatible

with the IO-Link SSP 3.3 smart sensor profile for measuring

sensors with disable function.

CUSTOMER VALUES

HIGHLY ACCURATE, REPEATABLE SENSING PERFORMANCE IN

EMBEDDABLE INDUCTIVE SMART SENSORS DIFFERENTIATE

CLEARLY BETWEEN TARGET MATERIAL TYPES, DETECTING

NON-FERROUS METAL AND TRIGGERING SEPARATION

ACCURATELY AND RELIABLY

A SINGLE ARRAY OF SENSORS PROVIDES CONTINUOUS

DETECTION ACROSS THE FULL WIDTH OF A CONVEYOR

SMART SENSORS EASILY ABLE TO IDENTIFY MATERIAL ON

FAST-MOVING CONVEYORS THANKS TO HIGH SENSING SPEED

INDUSTRY-STANDARD IO-LINK CONNECTIVITY PROVIDES A

SINGLE INTERFACE TO THE MACHINE CONTROL SYSTEM

CUMULATIVE OPERATING DATA FOR PREDICTIVE

MAINTENANCE, INCLUDING TEMPERATURE AND OPERATING-

CYCLE COUNT, IS RECORDED IN ON-BOARD DATA STORAGE

SENSOR CONFIGURATIONS ARE STORED LOCALLY, ALLOWING

PLUG-AND-PLAY REPLACEMENT OF SENSORS WHEN NEEDED

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-AND-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE SMART SENSORS ARE

IDEAL FOR EASY INTEGRATION

MULTI-CHANNEL MONITORING CIRCUITRY ALLOWS USERS TO

DEFINE 5 CUSTOMISED OUTPUT THRESHOLDS

SOPHISTICATED SENSING ELECTRONICS DELIVER HIGH-

PRECISION ANALOGUE OUTPUT SIGNALS

HIGH-SPEED DEVICE-TO-DEVICE COMMUNICATION ENABLES

DECENTRALISED DATA-PROCESSING AND DECISION MAKING

SMART SENSORS ARE INDIVIDUALLY SHIELDED AND EMC

IMMUNE, ELIMINATING INTERFERENCE WHEN MULTIPLE

DEVICES OPERATE IN CLOSE PROXIMITY

DEDICATED SERVICE-DATA BLOCKS HOLD DEVICE-SPECIFIC

DATA INCLUDING PRODUCT ID, LOCATION & SERIAL NUMBER

LEDS ENABLE SENSORS TO SELF-IDENTIFY ON DEMAND,

SIMPLIFYING COMMISSIONING & TROUBLE-SHOOTING

INDUSTRY-STANDARD -25°C TO +70°C OPERATING RANGE

The recycling industry utilises automation to reduce the cost of

sorting and separating mixed-metal scrap. One such solution

is automated sorting, which requires sensors which both

operate accurately and at high speed to identify and separate

fast-moving streams of ferrous and non-ferrous material in a

single pass. Rugged inductive Smart Sensors from Contrinex,

are embedded immediately below the delivery belt to provide

continuous high-speed detection across the full width of a

conveyor belt.

CUSTOMER APPLICATION

The global recycling industry relies upon advances in

technology to automate waste-recovery operations. These

make it economic to recover an ever greater proportion of

domestic and industrial waste. Waste-management

companies are always looking for more affordable alternatives

for sorting and separating mixed-metal scrap as some of the

existing processes, while effective, are inflexible and expensive.

Advances in sensor technology and capabilities have seen the

introduction of induction sorting, a process that identifies and

separates different types of metallic material. A fast-moving

conveyor carries pre-sized waste over a bank of inductive

sensors mounted below the belt; the sensors detect and

identify any non-ferrous material, which is subsequently

ejected and separated by a targeted air-knife.

To take full advantage of the process, OEM equipment builders

require robust sensors that differentiate accurately and at high

speed between ferrous and non-ferrous material, allowing a

single bank of sensors to process mixed-metal waste in a

single pass. As the sensors may operate independently or in

combination with other sensing technologies, an industry-

standard communication interface is highly desirable.

CUSTOMER SOLUTION

Designers specified rugged inductive sensors from the

Contrinex Smart Sensor portfolio; an array of 50 metal-cased

sensors, embedded in a grid pattern immediately below the

belt, provides continuous detection across the full width of the

conveyor. Best-practice electronic design ensures that Smart

Sensors are individually shielded and EMC immune,

eliminating interference when multiple devices operate in

close proximity.

Mounted only a few millimetres from the target as it passes

overhead, these M18 devices, which have a nominal sensing

distance of 10 mm for carbon steel, generate analogue output

signals that vary according to the material type. The Smart

Sensors are easily able to accommodate the required range of

conveyor speeds.

IO-Link connectivity, standard across the range, provides an

industry-standard interface to the machine control system,

triggering the appropriate air-knives as pieces of non-ferrous

material reach the separator. During initial calibration, each

sensor’s configuration is stored automatically on the local IO-

Link Master; this allows plug-and-play replacement of sensors

should the need arise, without any loss of functionality and

without any need for recalibration.

Contrinex inductive Smart Sensors are designed with the

needs of OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. On-board data storage

holds cumulative operating data for user-specified purposes,

including predictive maintenance. These highly versatile

sensors meet designers’ needs for a robust and cost-effective

solution that delivers exceptional accuracy and reliability in a

particularly challenging environment.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS