(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

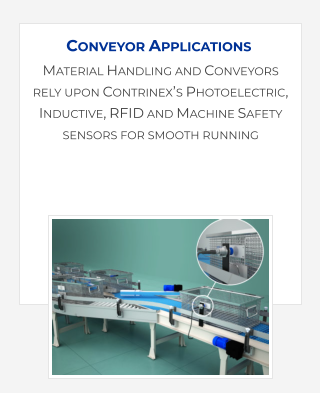

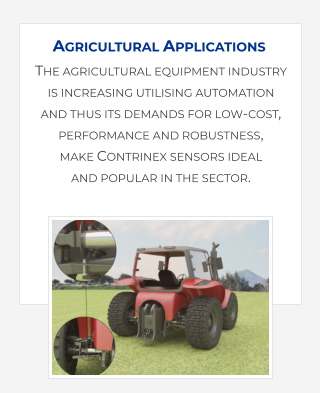

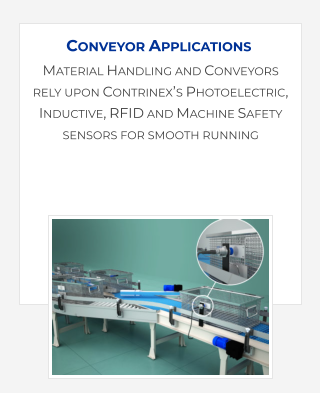

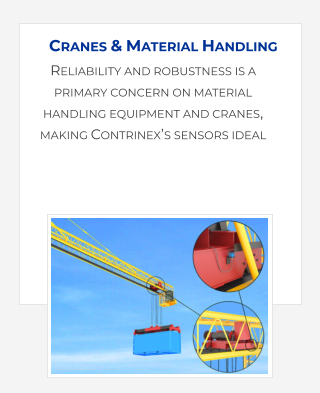

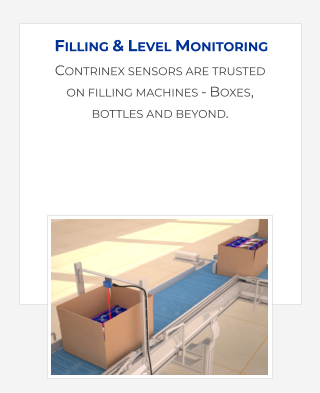

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER SOLUTION

Contrinex fork light-barrier sensors combine simplicity of

installation, compact and robust construction and multi-mode

operation. They offer high-resolution, high-speed sensing plus

IO-Link connectivity, being ideal for position sensing and

presence detection.

The versatile, metal-cased devices offer designers the choice of

four discrete operating modes and switching frequencies up

to 14,000Hz. With a standard resolution of 0.3 mm (down to 0.1

mm in high-resolution mode), with the convenience of a push-

pull output.

The industry-standard IO-Link communication protocol,

provides a choice of manual or remote set-up and adjustment,

enabling the sensor to be automatically reconfigured between

different product production runs.

simplifying installation while saving time and money.

The product range offers a choice of fork openings from 10

mm to 120 mm, to suit a wide variety of applications and

environments, whilst saving time and money.

Food production utilises automation to achieve high-efficiency

and for example a processing plant trusts Contrinex Fork

photoelectric sensors to help it ensure plastic bottles, filled

with liquid food products, are hermetically sealed and capped

to keep its customers kept safe.

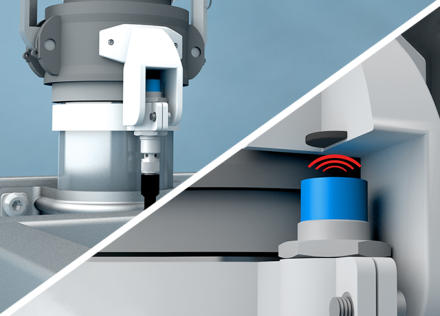

Prior to fitting plastic caps a long-distance inductive sensor

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

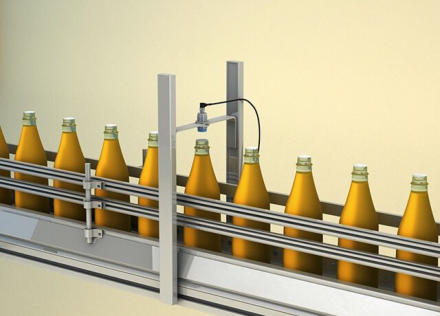

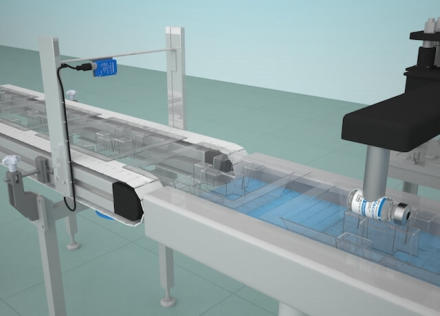

In the continuous production of fast-moving items, line

stoppages are both costly and time consuming. After filling,

sealing and capping, bottles of ketchups and sauces are

labelled and packaged. Previously, if a plastic cap was missing

it could go undetected, risking an entire batch of production

potentially being rejected.

Contrinex’s highly versatile photoelectric fork sensor, is

positioned directly over the conveyor to sense the presence of

a cap on each bottle prior to labelling, triggering an alarm if a

cap is missing.

PRODUCT ADVANTAGES

HIGH FREQUENCY UP TO 14 KHZ

4 SELECTABLE MODES BETWEEN PRODUCTION BATCHES:

STANDARD, HIGH RESOLUTION, POWER, SPEED

IO-LINK V1.1 COMMUNICATION PROTOCOL

SENSITIVITY ADJUSTMENT ALLOWING DETECTION OF

TRANSPARENT OBJECTS

PRECISE ALIGNMENT REQUIRES NO ON-SITE ADJUSTMENT

ACCURACY AND RELIABILITY IS ESSENTIAL IN FILLING MACHINES AND CONTRINEX’S

SENSORS EXCEL IN THIS, AND OFFER CLASS-LEADING PRICE PERFORMANCE.

ADVANCED FEATURES INCLUDE PREVENTATIVE-MAINTENANCE OUTPUTS; IP69K

CIP-WASHDOWN RATINGS; UV TRANSPARENT-OBJECT DETECTION; MAKE THEM POPULAR.

THE WORLD’S LARGEST SELECTION OF IO-LINK SENSORS PROVIDE ADDITIONAL PERFORMANCE

DATA IN A CONSISTENT MANNER AND HELPS MAKE IOT / INDUSTRY 4 CONNECTIVITY EASIER.

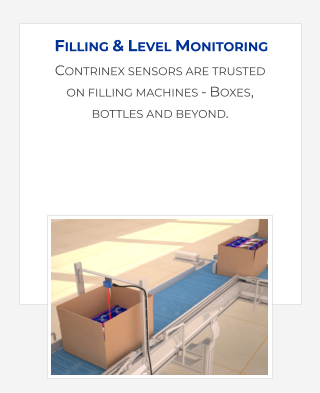

FILLING APPLICATIONS

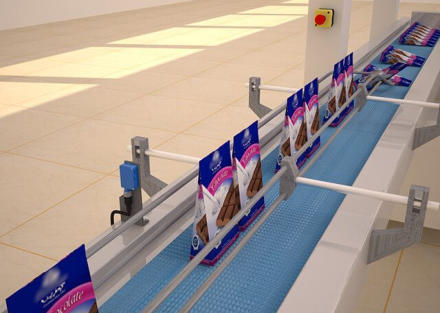

During high-speed production of retail bags, a confectionery

manufacturer conveys individual bags of sweets to a pick-and-

place packing robot for secondary packaging. A highly reliable

diffuse-mode photoelectric sensor, mounted beside the

conveyor, detects the presence of bags as they approach the

packing station and inhibits the pick-and-place sequence if no

bags are queued for the packing robots.

CUSTOMER APPLICATION

In the food-processing industry, consumer products generally

require secondary packaging – both for consolidation and for

protection, before final dispatch. During confectionery

production, individual bags of sweets travel by conveyor from

bagging stations to a pick-and-place packing robot for

secondary packaging, before passing on to the labelling and

packing area.

Ideally, product flow along the conveyor is continuous; in

practice, interruptions occur from time to time as bagging

machines require attention. In the absence of bagged

products arriving at the secondary-packaging station, a plant-

wide control system prevents operation of the pick-and-place

robot to prevent miss-filling.

Immediately prior to arrival at the secondary-packaging

station, custom-formed guide rails align bags for packing.

Space is limited and there is no easy access to both sides of the

conveyor. A highly reliable non-contact sensor system was

needed to detect the presence of bags as they approach the

alignment rails; the system must inhibit the pick-and-place

sequence if no bags are queued for packing

CUSTOMER SOLUTION

Diffuse-mode photoelectric sensors from the Contrinex C23PA

family of sensors are ideal for this application. These highly

reliable devices contain both a transmitter and a receiver and

do not require a separate reflector, instead relying on the

reflective nature of the target. Space constraints are

accommodated without compromise, thanks to a maximum

sensing range of 3 to 1500mm. This is adjustable via a pre-set

potentiometer or via IO-Link, the standardised point-to-point

serial connection protocol.

Immediately before the alignment rails, a single sensor is

mounted beside the conveyor; positioning sensors is simple

thanks to a range of adjustable mounting brackets. As each

bag passes in front of the sensor, its presence triggers the

device, sending a signal to the customer’s control system. A

high-intensity red LED with a 15mm-diameter light spot at the

selected 500mm sensing range ensures highly reliable

detection of bags in real-time.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE TESTING OF A RANGE OF

DIFFERENT-SIZED CONTAINERS

TESTING IS COMPLETED AT PRODUCTION-LINE SPEED

IMMEDIATE IDENTIFICATION OF MISSING CLOSURES

ELIMINATION OF MANUAL INSPECTION AND POTENTIAL BATCH

REJECTION

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 40MM

UNMATCHED COMBINATION OF 40MM SENSING DISTANCE IN

M30-DIAMETER DEVICE

CUSTOMER SOLUTION

Contrinex fork light-barrier sensors combine simplicity of

installation, compact and robust construction and multi-mode

operation. They offer high-resolution, high-speed sensing plus

IO-Link connectivity, being ideal for position sensing and

presence detection.

The versatile, metal-cased devices offer designers the choice of

four discrete operating modes and switching frequencies up

to 14,000Hz. With a standard resolution of 0.3 mm (down to 0.1

mm in high-resolution mode), with the convenience of a push-

pull output.

The industry-standard IO-Link communication protocol,

provides a choice of manual or remote set-up and adjustment,

enabling the sensor to be automatically reconfigured between

different product production runs.

simplifying installation while saving time and money.

The product range offers a choice of fork openings from 10

mm to 120 mm, to suit a wide variety of applications and

environments, whilst saving time and money.

A food-processing plant trusts Contrinex’s sensors to help it

ensure plastic bottles, filled with liquid food products, are

hermetically sealed and its customers kept safe. Prior to the

containers being capped, a long-distance inductive sensor,

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

Aluminium-foil closures are commonly utilised as seals for

plastic containers filled with ketchup, mustard and other table

sauces. At a food-processing plant, closures are applied to

filled containers passing along an automated production line,

sealing the contents ready for capping and bulk packaging.

Customer Solution

Contrinex ultrasonic sensors are ideal for presence- and level-

sensing applications, and a diffuse sensor from the Compact

range (housing size M30) is an excellent choice for this

application. Operating range for this metal-bodied, IP65-rated

device is between 20cm and 130cm; detection is independent

of the target’s color, shape, material or surface structure.

Contrinex Compact ultrasonic sensors feature an integral S12

cable connector, allowing rapid disconnection and removal

when required.

The variable size and shape of meat residue makes it difficult

for an uncompensated sensor to detect contamination

consistently and reliably; potentiometer adjustment, provided

by many manufacturers, is inadequate for this application.

Contrinex CONPROG software for Windows®, connected via

the APE-0000-001 PC interface, compensates perfectly.

Using CONPROG, the operator characterizes the target area of

the box during set-up, setting the exact operating parameters

of the sensor and ensuring reliable detection. Sensor data is

stored, allowing like-for-like sensor replacement without

additional set-up.

The sensor’s three-wire PNP normally-open output

communicates directly with the customer PLC. On detection

of a contaminated box, a mechanical diverter shunts the box

to a separate conveyor for manual emptying.

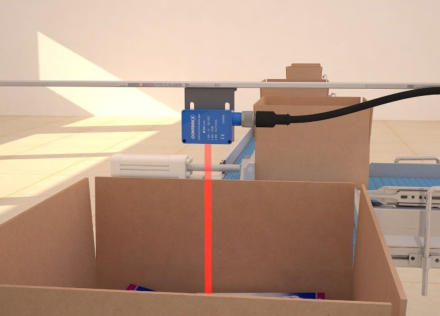

A meat-processing plant uses non-contact ultrasonic presence

sensing to increase productivity and eliminate breakdowns

when washing empty meat bins. A single ultrasonic sensor,

mounted above the conveyor on which the bins travel, checks

for meat residues, rejecting any contaminated bins before the

wash station. Old, contact-based systems were unreliable,

resulting in breakdowns and frequent interruptions to the

washing process.

CUSTOMER APPLICATION

During production, an industrial meat-processing company

conveys meat portions around its factory in food-grade plastic

bins. After completion of each batch, empty bins are washed

prior to reuse. Some bins contain sizeable pieces of meat

which, if undetected, accumulate in the washing machine,

causing blockages and breakdowns. The resulting

interruptions to production are unacceptably frequent.

A reliable sensor system must detect the presence of meat

residues in bins as they travel along the conveyor. The sensor

should identify all non-trivial residues and divert contaminated

bins before they enter the washing station. The system should

require little or no regular maintenance, and a non-contact

sensor, suitable for a hygienic environment, is preferred.

Old systems with spring-loaded wand-actuators in contact

with the box are unreliable and require regular adjustment;

the contact probes need frequent, time-consuming cleaning.

The new system has to operate on a fit-and-forget basis.

CUSTOMER VALUES

IMPROVED SENSOR RELIABILITY DERIVED FROM EXACT

CHARACTERISATION OF TARGET

INCREASED PRODUCTIVITY ARISING FROM ELIMINATION OF

BREAKDOWNS

REDUCED SENSOR MAINTENANCE RESULTING FROM NON-

CONTACT OPERATION

INDUSTRY-STANDARD INTERFACE REQUIRES LITTLE

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

ECOLAB-CERTIFIED PHOTOELECTRIC SENSORS WITH

BACKGROUND-SUPPRESSION MODE

CHARACTERISED SENSORS DETECT TARGETS OF VARIABLE SIZE

AND SHAPE

LONG-DISTANCE, NON-CONTACT OPERATING PRINCIPLES

IP65 PROTECTION ALLOWS OPERATION IN HYGIENIC

ENVIRONMENTS

RUGGED ULTRASONIC SENSOR WITH METAL HOUSING AND

METAL CABLE CONNECTOR

CUSTOMER VALUES

INDUSTRY-STANDARD IO-LINK INTERFACE ENSURES RELIABLE

OUT-OF-THE-BOX CONNECTIVITY

DUAL-MODE READ-WRITE MODULES DELIVER ULTIMATE

FLEXIBILITY

STANDARD I/O MODE OPERATION PROVIDES DECENTRALISED,

LOCAL INTELLIGENCE

IO-LINK MODE OPERATION PROVIDES CENTRALISED

INTELLIGENCE

PLANT-WIDE COMMONALITY OF RWM HARDWARE MINIMIZES

SPARES INVENTORY HOLDING

INTEGRAL M12 CONNECTORS ENSURE EASY INSTALLATION

AND REPLACEMENT

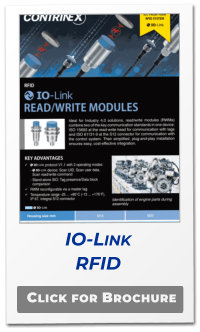

PRODUCT ADVANTAGES

IO-LINK V1.1 COMPATIBILITY

ROBUST METAL HOUSINGS WITH PBTB SENSING FACES

SENSING DISTANCES UP TO 60MM

RECONFIGURABLE REMOTELY OR VIA MASTER TAG

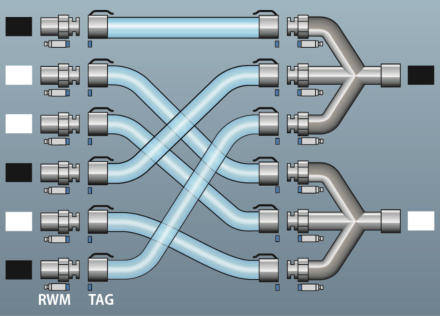

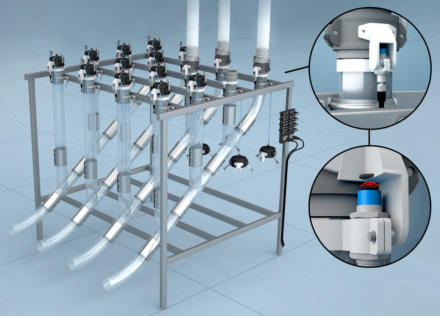

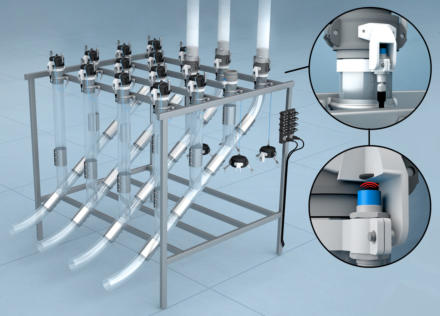

Bulk-handling and pneumatic transport system designers use

RFID technology to eliminate connection errors at manual

hose-coupling stations for fluidisable materials. Coupling

stations, with IO-Link enabled read/write modules (RWMs)

mounted on each outlet pipe, use manual quick-release hoses

to feed materials to multiple machines. RFID tags, mounted

integrally within each hose coupling and blanking cap, identify

the mating parts uniquely, allowing individual outlet/hose

combinations to be verified at the time of connection.

CUSTOMER APPLICATION

Bulk-handling systems across diverse industries, including

food processing, plastics and pharmaceuticals, rely heavily on

pneumatic conveying systems for transporting powders,

granulates and other fluidisable materials. Pneumatic

conveyors offer quick, reliable high-volume transportation with

minimum degradation of the transported material.

Coupling stations offer a simple and cost-effective means of

connecting several material sources, typically silos or storage

bins, to multiple processing machines. A pipe from each

source enters the bottom of the coupling station, where it

branches, providing multiple outlets for each material. Quick-

release hoses, connected manually to the corresponding

outlets, feed materials to machines. Unused outlets are

capped.

CUSTOMER VALUES

SAFE, RELIABLE OPERATION IN A HOSTILE WASHDOWN

ENVIRONMENT

NO RISK OF CROSS-CONTAMINATION BETWEEN PROCESSING

AND CLEANING SEQUENCES

EASY INTEGRATION WITH EXISTING PLANT-WIDE CONTROL

SYSTEM

COST-EFFECTIVE SOLUTION REQUIRING MINIMAL

MAINTENANCE

PRODUCT ADVANTAGES

IP68/ IP69K RATED HOUSING, FOOD-COMPATIBLE BODY

EXCEPTIONAL RESISTANCE TO SHOCK AND VIBRATION

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH EXCELLENT

RELIABILITY

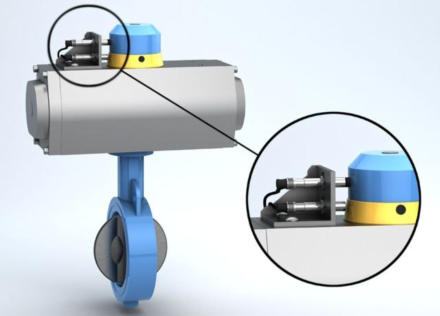

During manufacture of dairy products, raw milk travels

between successive processes through stainless-steel

pipework. Rotary-shaft control valves maintain process

sequences correctly, ensuring that no cross-contamination

occurs during CIP cleaning after each batch is completed.

Robust washdown inductive sensors, mounted on existing

rotary actuators, monitor control-valve status around the clock,

providing real-time positional feedback to a plant-wide control

system in a simple, cost-effective manner.

CUSTOMER APPLICATION

At a European dairy-processing plant, milk products, made

from pasteurized or raw milk, require hygienic transportation

between successive operations. Process engineers use

stainless-steel pipework to transport liquid ingredients from

one operation to the next. Fluid flow is managed using control

valves fitted with electrical, hydraulic or pneumatic actuators.

Multiple rotary-shaft valves deliver raw milk from holding

tanks to each process station in sequence, maintaining

specified flow rates and volumetric limits. Once processing of

each batch is completed and all process vessels are drained,

closed-loop CIP cleaning commences. Accurate, repeatable

valve sequencing is essential to prevent any chance of cross-

contamination between processing and cleaning sequences.

A robust, highly reliable sensor system, capable of

withstanding the harsh washdown regimes in force, is needed

to monitor control-valve positions during processing. Where

possible, sensors must be mounted on existing rotary

actuators, and real-time communication with existing plant-

wide control systems is mandatory.

Customer Solution

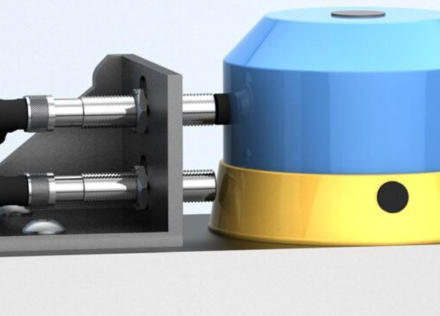

Sensing the position of a rotary-valve actuator is a routine task

for Contrinex Classics washdown inductive sensors. These

sensors interface directly with a range of industrial process

controllers and provide cost-effective confirmation of control-

valve status around the clock.

A purpose-designed bracket, mounted on the top surface of

each actuator, holds two sensors; these are positioned with the

sensing faces vertically aligned, one above the other, and

facing the actuator shaft. NAMUR-compatible (VDE/VDI 3845)

mountings on the actuators provide a known datum for the

sensors.

A solid plastic disc, mounted on the shaft, carries two or more

stainless-steel targets, positioned at 90 degrees to each other

around the outer peripheral surface of the disc. Each target

occupies either an upper or a lower position corresponding to

height of one of the sensors. As the shaft rotates, opening and

closing the valve, the targets pass in front of the sensing faces,

triggering the sensors.

These M12-diameter devices, rated to IP68/IP69K, have all-

metal bodies with PBTB sensing faces and vacuum-

encapsulated electronics; each features an industry-standard

PNP normally open output. Fully embeddable, and with a

sensing range up to 2mm, they are well suited to the hostile

operating conditions of a washdown environment.

Each sensor has an integral M12 connector, interfacing with

the customer’s control system via a TPE-S-sheathed cable.

Reliability is excellent; the system is simple and cost-effective.

Human error can result in hoses being connected to the

wrong outlet, causing costly errors if undetected; systems

designers require real-time confirmation that the correct hose

has been connected to each outlet, or, where no connection is

specified, that a blanking cap is in place. An industry-standard

interface is highly desirable; ultra-high-speed communication

is not essential.

Customer Solution

IO-Link-enabled high-frequency (HF) read-write modules

(RWMs) and RFID tags from Contrinex are ideal for this

application. An IO-Link-enabled RWM, mounted on each

outlet pipe, is connected to a plant-wide control system via

two industry-standard 8-way IO-Link master hubs. An RFID

tag, mounted integrally within each hose coupling, identifies

the hose uniquely, allowing the outlet/hose combination to be

verified at the time of connection. Blanking caps also carry

unique RFID tags to confirm that unused outlets are capped.

The mechanical design of the RWM and tag mountings

ensures that the coupling or cap can only be locked in place

once the components are aligned accurately. With data-

transfer rates up to 38.4k baud, the sensors provide data in real

time, triggering an immediate alarm in the event of a

connection error.

Contrinex IO-Link RWMs are configurable to operate in one of

two discrete modes: IO-Link mode allows remote

communication via the standard protocol; alternatively, if local

control is preferred, standard I/O mode allows the device to

function as an intelligent presence-sensing sensor. Process

engineers can switch RWMs between modes either remotely,

using the IO-Link protocol itself, or locally, using a pre-

configured RFID tag (a Master Tag) which is simply placed on

top of the RWM during the RWM startup process.

With sensing distances up to 60 mm, robust M18- and M30-

threaded metal housings and integral M12 connectors,

Contrinex RWMs are ideally suited to the environment of a

busy industrial processing plant. They are compatible with all

ISO/IEC 15693 approved RFID tags, allowing designers ultimate

flexibility and excellent value for money.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

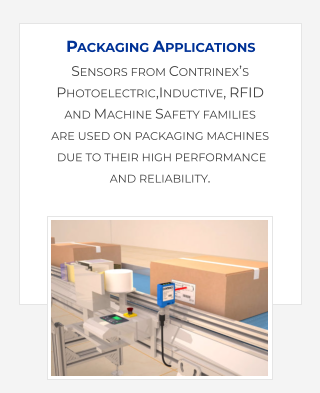

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP versions

I

CUSTOMER VALUES

SAFE DETECTION OF THE THINNEST TRANSPARENT MATERIALS

MAXIMUM OPERATING RESERVE OWING TO HIGH ABSORPTION

FACTOR OF UV LIGHT BY TRANSPARENT PLASTICS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

RELIABLE OPERATION WITHOUT THE NEED FOR MANUAL

INTERVENTION

VERY LOW SENSITIVITY TO DUST, LIQUID DROPLETS AND

SPLASHES

PRODUCT ADVANTAGES

REMOTE SENSITIVITY RETRIEVAL OR UPDATE VIA IO-LINK

IO-LINK SERIAL-CONNECTION PROTOCOL ENABLED ON PNP

VERSIONS AT NO ADDITIONAL COST

PRE-TAUGHT SENSITIVITY PARAMETERS STORED ON INBUILT

SENSOR MEMORY

HIGHLY TOLERANT OF CONTAMINATION BY DUST, LIQUID

DROPLETS OR SPLASHES

During the automated packaging of fast-moving products,

thermoformed transparent plastic tray bases are common.

Contrinex’s small C23 transparent-object sensor with patented

UV technology detects the presence of each set of transparent

trays after it is formed, initiating a subsequent operation and,

optionally, triggering a counting circuit. The Ecolab-

certification of these sensors make them suitable for the

packaging of food and medical products.

CUSTOMER APPLICATION

A manufacturer of packaging machines for the medical

industry produces automated blister-packaging lines for

pharmaceutical and surgical products. Medical blister-packs

comprise a recessed, semi-rigid tray base, vacuum-formed in-

line from a clear thermoplastic material and sealed with a

metal or plastic film after the desired products are loaded.

Typically, blister-packaging lines for surgical products operate

in sterile conditions; minimal manual intervention is permitted,

as contamination may enter the environment. If defective

bases are identified and rejected after forming, the flow of tray

bases to the loading station is not continuous. In this event, a

sensor system must inhibit the loading cycle until a base is in

position.

Sensors must detect the presence of transparent tray bases

swiftly and reliably, enabling the loading cycle to proceed with

minimal delay as soon as a tray is present at the loading

station. Standard photoelectric sensors, which use visible red-

light sources, proved unreliable as they are unable to

differentiate reliably between ‘tray present’ and ‘tray not

present’ conditions.

An alternative sensor is required which will detect the

presence of a transparent plastic target under normal

operating conditions

CUSTOMER SOLUTION

Transparent-object sensors with ultraviolet LED-light sources

from the Contrinex C23 product series are ideally suited to this

application. These miniature cubic devices, mounted above

product conveyors, detect the presence of transparent tray

bases as they arrive at the loading station. Positioning sensors

is simple thanks to a range of adjustable mounting brackets,

and auto-collimated optics ensure there are no blind zones.

Contrinex transparent-object sensors utilize a patented reflex

operating principle with polarized ultraviolet light at 275 nm.

At this wavelength, absorption of the polarized UV light by a

range of commonly used plastics is maximized. Custom-

designed UV reflectors, using high-tech plastic materials with

excellent reflective properties in the ultraviolet range, provide a

range of sizes and geometries that simplify installation.

An industry-standard PNP normally open output ensures

optimum flexibility. Additionally, IO-Link, a standardized point-

to-point serial connection protocol for sensors and actuators, is

enabled on PNP versions at no additional cost. An additional

option is to have a second output to provide the stability alarm

in the event of reduced sensitivity, flagging the need for

preventative maintenance before any performance

degradation occurs.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings. A sensing range up

to 1200 mm, adjustable via a teach button or via IO-Link,

accommodates a wide range of machine geometries.

Sensitivity parameters are stored on the sensor’s inbuilt

memory and may be retrieved or updated remotely via IO-

Link, eliminating the need for manual adjustment.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings, are corrosion-

resistant and impervious to water ingress and has the

additional benefit of offering a range of low-cost stainless-steel

mounting and protection bracketry.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

FILLING APPLICATIONS

CONTRINEX’S PHOTOELECTRIC, INDUCTIVE, RFID

AND MACHINE SAFETY SENSORS ARE TRUSTED

ACROSS THE MANY ASPECTS OF FOOD & BEVERAGE

MANUFACTURING AND PACKAGING.

IMPROVE MACHINE PERFORMANCE WITH SUPERIOR

SENSOR PERFORMANCE, PLUS ADDED FEATURES LIKE

PREVENTATIVE-MAINTENANCE OUTPUTS; IP69K

CIP-WASHDOWN INDUCTIVE; SAFETY & RFID

SENSORS; UV TRANSPARENT-OBJECT DETECTION;

PLUS THE WORLD’S LARGEST SELECTION OF IO-LINK

SENSORS PROVIDING ADDITIONAL PERFORMANCE

DATA IN A CONSISTENT MANNER AND EASY IOT /

INDUSTRY 4 CONNECTIVITY.

.

CUSTOMER VALUES

INDUSTRY-STANDARD IO-LINK INTERFACE ENSURES RELIABLE

OUT-OF-THE-BOX CONNECTIVITY

DUAL-MODE READ-WRITE MODULES DELIVER ULTIMATE

FLEXIBILITY

STANDARD I/O MODE OPERATION PROVIDES DECENTRALISED,

LOCAL INTELLIGENCE

IO-LINK MODE OPERATION PROVIDES CENTRALISED

INTELLIGENCE

PLANT-WIDE COMMONALITY OF RWM HARDWARE MINIMIZES

SPARES INVENTORY HOLDING

INTEGRAL M12 CONNECTORS ENSURE EASY INSTALLATION

AND REPLACEMENT

PRODUCT ADVANTAGES

IO-LINK V1.1 COMPATIBILITY

ROBUST METAL HOUSINGS WITH PBTB SENSING FACES

SENSING DISTANCES UP TO 60MM

RECONFIGURABLE REMOTELY OR VIA MASTER TAG

A manufacturer of automated conveyor systems uses RFID

technology to monitor the location of items and to route them

to their chosen destinations. As an basket, fitted with an RFID

transponder tag, travels through the warehouse, IO-Link-

enabled high-frequency read-write modules (RWMs) monitor

its position and read pre-set data stored in the tag.

Local logic capability enables a read-write module to trigger a

conveyor diverter, routing the item without reference to a

centralised PLC-based control system.

CUSTOMER APPLICATION

An OEM manufacturer of automated conveyor systems for the

distribution sector uses RFID technology to monitor the

location of items as they pass through a warehouse. Designers

also required local control of two-way conveyor diverters to

route items to the correct destination;. Therefore generic

information stored on each RFID transponder tag determines

the required diverter position and thus an item’s destination.

Location monitoring relies on a plant-wide PLC-based control

system. An industry-standard interface with the RFID modules

is highly desirable as this allows the use of existing libraries of

PLC function blocks, avoiding the need for custom PLC code.

Ultra-high-speed communication is not essential as conveyor

speeds are moderate.

Local diverter switching relies solely on the information

contained in an item’s RFID tag; communication with the

centralized system is unnecessary. Response time must be no

more than 200 milliseconds to allow the diverter to operate

before the item reaches the switch point.

Customer Solution

IO-Link-enabled high-frequency (HF) read-write modules

(RWMs) and RFID tags from Contrinex are ideal for this

application. An IO-Link-enabled RWM, mounted on each

outlet pipe, is connected to a plant-wide control system via

two industry-standard 8-way IO-Link master hubs. An RFID

tag, mounted integrally within each hose coupling, identifies

the hose uniquely, allowing the outlet/hose combination to be

verified at the time of connection. Blanking caps also carry

unique RFID tags to confirm that unused outlets are capped.

The mechanical design of the RWM and tag mountings

ensures that the coupling or cap can only be locked in place

once the components are aligned accurately. With data-

transfer rates up to 38.4k baud, the sensors provide data in real

time, triggering an immediate alarm in the event of a

connection error.

Contrinex IO-Link RWMs are configurable to operate in one of

two discrete modes: IO-Link mode allows remote

communication via the standard protocol; alternatively, if local

control is preferred, standard I/O mode allows the device to

function as an intelligent presence-sensing sensor. Process

engineers can switch RWMs between modes either remotely,

using the IO-Link protocol itself, or locally, using a pre-

configured RFID tag (a Master Tag) which is simply placed on

top of the RWM during the RWM startup process.

With sensing distances up to 60 mm, robust M18- and M30-

threaded metal housings and integral M12 connectors,

Contrinex RWMs are ideally suited to the environment of a

busy industrial processing plant. They are compatible with all

ISO/IEC 15693 approved RFID tags, allowing designers ultimate

flexibility and excellent value for money.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP version.

During high-speed production of retail bags, a confectionery

manufacturer conveys individual bags of sweets to a pick-and-

place packing robot for secondary packaging. A highly reliable

diffuse-mode photoelectric sensor, mounted beside the

conveyor, detects the presence of bags as they approach the

packing station and inhibits the pick-and-place sequence if no

bags are queued for the packing robots.

CUSTOMER APPLICATION

In the food-processing industry, consumer products generally

require secondary packaging – both for consolidation and for

protection, before final dispatch. During confectionery

production, individual bags of sweets travel by conveyor from

bagging stations to a pick-and-place packing robot for

secondary packaging, before passing on to the labelling and

packing area.

Ideally, product flow along the conveyor is continuous; in

practice, interruptions occur from time to time as bagging

machines require attention. In the absence of bagged

products arriving at the secondary-packaging station, a plant-

wide control system prevents operation of the pick-and-place

robot to prevent miss-filling.

Immediately prior to arrival at the secondary-packaging

station, custom-formed guide rails align bags for packing.

Space is limited and there is no easy access to both sides of the

conveyor. A highly reliable non-contact sensor system was

needed to detect the presence of bags as they approach the

alignment rails; the system must inhibit the pick-and-place

sequence if no bags are queued for packing.

CUSTOMER SOLUTION

Diffuse-mode photoelectric sensors from the Contrinex C23PA

family of sensors are ideal for this application. These highly

reliable devices contain both a transmitter and a receiver and

do not require a separate reflector, instead relying on the

reflective nature of the target. Space constraints are

accommodated without compromise, thanks to a maximum

sensing range of 3 to 1500mm. This is adjustable via a pre-set

potentiometer or via IO-Link, the standardised point-to-point

serial connection protocol.

Immediately before the alignment rails, a single sensor is

mounted beside the conveyor; positioning sensors is simple

thanks to a range of adjustable mounting brackets. As each

bag passes in front of the sensor, its presence triggers the

device, sending a signal to the customer’s control system. A

high-intensity red LED with a 15mm-diameter light spot at the

selected 500mm sensing range ensures highly reliable

detection of bags in real-time.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

The sensors are corrosion-resistant and impervious to water

ingress and has the additional benefit of offering a range of

low-cost stainless-steel mounting and protection bracketry.

The reliability of the sensors in the application has been

excellent.

CUSTOMER VALUES

SAFE, RELIABLE OPERATION IN A HOSTILE WASHDOWN

ENVIRONMENT

NO RISK OF CROSS-CONTAMINATION BETWEEN PROCESSING

AND CLEANING SEQUENCES

EASY INTEGRATION WITH EXISTING PLANT-WIDE CONTROL

SYSTEM

COST-EFFECTIVE SOLUTION REQUIRING MINIMAL

MAINTENANCE

PRODUCT ADVANTAGES

IP68/ IP69K RATED HOUSING, FOOD-COMPATIBLE BODY

EXCEPTIONAL RESISTANCE TO SHOCK AND VIBRATION

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH EXCELLENT

RELIABILITY

During manufacture of dairy products, raw milk travels

between successive processes through stainless-steel

pipework. Rotary-shaft control valves maintain process

sequences correctly, ensuring that no cross-contamination

occurs during CIP cleaning after each batch is completed.

Robust washdown inductive sensors, mounted on existing

rotary actuators, monitor control-valve status around the clock,

providing real-time positional feedback to a plant-wide control

system in a simple, cost-effective manner.

CUSTOMER APPLICATION

At a European dairy-processing plant, milk products, made

from pasteurized or raw milk, require hygienic transportation

between successive operations. Process engineers use

stainless-steel pipework to transport liquid ingredients from

one operation to the next. Fluid flow is managed using control

valves fitted with electrical, hydraulic or pneumatic actuators.

Multiple rotary-shaft valves deliver raw milk from holding

tanks to each process station in sequence, maintaining

specified flow rates and volumetric limits. Once processing of

each batch is completed and all process vessels are drained,

closed-loop CIP cleaning commences. Accurate, repeatable

valve sequencing is essential to prevent any chance of cross-

contamination between processing and cleaning sequences.

A robust, highly reliable sensor system, capable of

withstanding the harsh washdown regimes in force, is needed

to monitor control-valve positions during processing. Where

possible, sensors must be mounted on existing rotary

actuators, and real-time communication with existing plant-

wide control systems is mandatory.

Customer Solution

Sensing the position of a rotary-valve actuator is a routine task

for Contrinex Classics washdown inductive sensors. These

sensors interface directly with a range of industrial process

controllers and provide cost-effective confirmation of control-

valve status around the clock.

A purpose-designed bracket, mounted on the top surface of

each actuator, holds two sensors; these are positioned with the

sensing faces vertically aligned, one above the other, and

facing the actuator shaft. NAMUR-compatible (VDE/VDI 3845)

mountings on the actuators provide a known datum for the

sensors.

A solid plastic disc, mounted on the shaft, carries two or more

stainless-steel targets, positioned at 90 degrees to each other

around the outer peripheral surface of the disc. Each target

occupies either an upper or a lower position corresponding to

height of one of the sensors. As the shaft rotates, opening and

closing the valve, the targets pass in front of the sensing faces,

triggering the sensors.

These M12-diameter devices, rated to IP68/IP69K, have all-

metal bodies with PBTB sensing faces and vacuum-

encapsulated electronics; each features an industry-standard

PNP normally open output. Fully embeddable, and with a

sensing range up to 2mm, they are well suited to the hostile

operating conditions of a washdown environment.

Each sensor has an integral M12 connector, interfacing with

the customer’s control system via a TPE-S-sheathed cable.

Reliability is excellent; the system is simple and cost-effective.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE TESTING OF A RANGE OF

DIFFERENT-SIZED CONTAINERS

TESTING IS COMPLETED AT PRODUCTION-LINE SPEED

IMMEDIATE IDENTIFICATION OF MISSING CLOSURES

ELIMINATION OF MANUAL INSPECTION AND POTENTIAL BATCH

REJECTION

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 40MM

UNMATCHED COMBINATION OF 40MM SENSING DISTANCE IN

M30-DIAMETER DEVICE

CUSTOMER SOLUTION

Contrinex Extra Distance inductive sensors are ideal for this

application, with the M30-diameter units operating reliably at

sensing distances up to 40mm; a single sensor thus

accommodates the entire range of container heights. Robust

construction with chrome-plated brass bodies and PBTP

sensing faces ensures that these devices are suitable for a busy

production environment.

A single sensor, located immediately after the sealing station

and positioned directly above the production line, provides

reliable, repeatable and fast detection of the aluminium-foil

closures. With a switching frequency of up to 100Hz, this Extra

Distance unit is well suited for fast-moving production where

high-speed sensing is required.

This Contrinex inductive sensor has an industry-standard PNP

normally-open interface and an integral M12 cable connector,

allowing easy removal and replacement of individual sensors

for maintenance. Connection to the customer’s test

equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of 40mm sensing distance

in an M30-diameter device, the customer can now test the

entire range of containers without adjusting the sensor height

between batches. Contrinex Extra Distance inductive sensors

deliver exceptionally reliable test results at production-line

speed, without interruption.

A food-processing plant trusts Contrinex’s sensors to help it

ensure plastic bottles, filled with liquid food products, are

hermetically sealed and its customers kept safe. Prior to the

containers being capped, a long-distance inductive sensor,

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

Aluminium-foil closures are commonly utilised as seals for

plastic containers filled with ketchup, mustard and other table

sauces. At a food-processing plant, closures are applied to

filled containers passing along an automated production line,

sealing the contents ready for capping and bulk packaging.

From time to time, equipment malfunctions can occur and

containers leave the sealing station without closures in place. If

unsealed containers are not detected prior to capping, entire

batches of product may require manual inspection, resulting

in lost production, down-time or potential rejection by

customers.

An in-line sensor system inspecting each container could

confirm the presence of a foil closure, rejecting any faulty

items. Each production line processes containers in batches.

The system must accommodate containers whose heights

vary by up to 20mm, without adjustment of sensors between

batches as successive batches may comprise containers of

differing sizes.

Customer Solution

Contrinex ultrasonic sensors are ideal for presence- and level-

sensing applications, and a diffuse sensor from the Compact

range (housing size M30) is an excellent choice for this

application. Operating range for this metal-bodied, IP65-rated

device is between 20cm and 130cm; detection is independent

of the target’s color, shape, material or surface structure.

Contrinex Compact ultrasonic sensors feature an integral S12

cable connector, allowing rapid disconnection and removal

when required.

The variable size and shape of meat residue makes it difficult

for an uncompensated sensor to detect contamination

consistently and reliably; potentiometer adjustment, provided

by many manufacturers, is inadequate for this application.

Contrinex CONPROG software for Windows®, connected via

the APE-0000-001 PC interface, compensates perfectly.

Using CONPROG, the operator characterizes the target area of

the box during set-up, setting the exact operating parameters

of the sensor and ensuring reliable detection. Sensor data is

stored, allowing like-for-like sensor replacement without

additional set-up.

The sensor’s three-wire PNP normally-open output

communicates directly with the customer PLC. On detection

of a contaminated box, a mechanical diverter shunts the box

to a separate conveyor for manual emptying.

A meat-processing plant uses non-contact ultrasonic presence

sensing to increase productivity and eliminate breakdowns

when washing empty meat bins. A single ultrasonic sensor,

mounted above the conveyor on which the bins travel, checks

for meat residues, rejecting any contaminated bins before the

wash station. Old, contact-based systems were unreliable,

resulting in breakdowns and frequent interruptions to the

washing process.

CUSTOMER APPLICATION

During production, an industrial meat-processing company

conveys meat portions around its factory in food-grade plastic

bins. After completion of each batch, empty bins are washed

prior to reuse. Some bins contain sizeable pieces of meat

which, if undetected, accumulate in the washing machine,

causing blockages and breakdowns. The resulting

interruptions to production are unacceptably frequent.

A reliable sensor system must detect the presence of meat

residues in bins as they travel along the conveyor. The sensor

should identify all non-trivial residues and divert contaminated

bins before they enter the washing station. The system should

require little or no regular maintenance, and a non-contact

sensor, suitable for a hygienic environment, is preferred.

Old systems with spring-loaded wand-actuators in contact

with the box are unreliable and require regular adjustment;

the contact probes need frequent, time-consuming cleaning.

The new system has to operate on a fit-and-forget basis.

CUSTOMER VALUES

IMPROVED SENSOR RELIABILITY DERIVED FROM EXACT

CHARACTERISATION OF TARGET

INCREASED PRODUCTIVITY ARISING FROM ELIMINATION OF

BREAKDOWNS

REDUCED SENSOR MAINTENANCE RESULTING FROM NON-

CONTACT OPERATION

INDUSTRY-STANDARD INTERFACE REQUIRES LITTLE

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

ECOLAB-CERTIFIED PHOTOELECTRIC SENSORS WITH

BACKGROUND-SUPPRESSION MODE

CHARACTERISED SENSORS DETECT TARGETS OF VARIABLE SIZE

AND SHAPE

LONG-DISTANCE, NON-CONTACT OPERATING PRINCIPLES

IP65 PROTECTION ALLOWS OPERATION IN HYGIENIC

ENVIRONMENTS

RUGGED ULTRASONIC SENSOR WITH METAL HOUSING AND

METAL CABLE CONNECTOR

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST ON

PNP VERSIONS• DUAL OUTPUT WITH STABILITY ALARM

CUSTOMER VALUES

SAFE DETECTION OF THE THINNEST TRANSPARENT MATERIALS

MAXIMUM OPERATING RESERVE OWING TO HIGH ABSORPTION

FACTOR OF UV LIGHT BY TRANSPARENT PLASTICS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

RELIABLE OPERATION WITHOUT THE NEED FOR MANUAL

INTERVENTION

VERY LOW SENSITIVITY TO DUST, LIQUID DROPLETS AND

SPLASHES

PRODUCT ADVANTAGES

REMOTE SENSITIVITY RETRIEVAL OR UPDATE VIA IO-LINK

IO-LINK SERIAL-CONNECTION PROTOCOL ENABLED ON PNP

VERSIONS AT NO ADDITIONAL COST

PRE-TAUGHT SENSITIVITY PARAMETERS STORED ON INBUILT

SENSOR MEMORY

HIGHLY TOLERANT OF CONTAMINATION BY DUST, LIQUID

DROPLETS OR SPLASHES

During the automated packaging of fast-moving products,

thermoformed transparent plastic tray bases are common.

Contrinex’s small C23 transparent-object sensor with patented

UV technology detects the presence of each set of transparent

trays after it is formed, initiating a subsequent operation and,

optionally, triggering a counting circuit. The Ecolab-

certification of these sensors make them suitable for the

packaging of food and medical products.

CUSTOMER APPLICATION

A manufacturer of packaging machines for the medical

industry produces automated blister-packaging lines for

pharmaceutical and surgical products. Medical blister-packs

comprise a recessed, semi-rigid tray base, vacuum-formed in-

line from a clear thermoplastic material and sealed with a

metal or plastic film after the desired products are loaded.

Typically, blister-packaging lines for surgical products operate

in sterile conditions; minimal manual intervention is permitted,

as contamination may enter the environment. If defective

bases are identified and rejected after forming, the flow of tray

bases to the loading station is not continuous. In this event, a

sensor system must inhibit the loading cycle until a base is in

position.

Sensors must detect the presence of transparent tray bases

swiftly and reliably, enabling the loading cycle to proceed with

minimal delay as soon as a tray is present at the loading

station. Standard photoelectric sensors, which use visible red-

light sources, proved unreliable as they are unable to

differentiate reliably between ‘tray present’ and ‘tray not

present’ conditions.

An alternative sensor is required which will detect the

presence of a transparent plastic target under normal

operating conditions

CUSTOMER SOLUTION

Transparent-object sensors with ultraviolet LED-light sources

from the Contrinex C23 product series are ideally suited to this

application. These miniature cubic devices, mounted above

product conveyors, detect the presence of transparent tray

bases as they arrive at the loading station. Positioning sensors

is simple thanks to a range of adjustable mounting brackets,

and auto-collimated optics ensure there are no blind zones.

Contrinex transparent-object sensors utilize a patented reflex

operating principle with polarized ultraviolet light at 275 nm.

At this wavelength, absorption of the polarized UV light by a

range of commonly used plastics is maximized. Custom-

designed UV reflectors, using high-tech plastic materials with

excellent reflective properties in the ultraviolet range, provide a

range of sizes and geometries that simplify installation.

An industry-standard PNP normally open output ensures

optimum flexibility. Additionally, IO-Link, a standardized point-

to-point serial connection protocol for sensors and actuators, is

enabled on PNP versions at no additional cost. An additional

option is to have a second output to provide the stability alarm

in the event of reduced sensitivity, flagging the need for

preventative maintenance before any performance

degradation occurs.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings. A sensing range up

to 1200 mm, adjustable via a teach button or via IO-Link,

accommodates a wide range of machine geometries.

Sensitivity parameters are stored on the sensor’s inbuilt

memory and may be retrieved or updated remotely via IO-

Link, eliminating the need for manual adjustment.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings, are corrosion-

resistant and impervious to water ingress and has the

additional benefit of offering a range of low-cost stainless-steel

mounting and protection bracketry.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WILL HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER SOLUTION

Contrinex fork light-barrier sensors combine simplicity of

installation, compact and robust construction and multi-mode

operation. They offer high-resolution, high-speed sensing plus

IO-Link connectivity, being ideal for position sensing and

presence detection.

The versatile, metal-cased devices offer designers the choice of

four discrete operating modes and switching frequencies up

to 14,000Hz. With a standard resolution of 0.3 mm (down to 0.1

mm in high-resolution mode), with the convenience of a push-

pull output.

The industry-standard IO-Link communication protocol,

provides a choice of manual or remote set-up and adjustment,

enabling the sensor to be automatically reconfigured between

different product production runs.

simplifying installation while saving time and money.

The product range offers a choice of fork openings from 10

mm to 120 mm, to suit a wide variety of applications and

environments, whilst saving time and money.

A food-processing plant trusts Contrinex’s sensors to help it

ensure plastic bottles, filled with liquid food products, are

hermetically sealed and its customers kept safe. Prior to the

containers being capped, a long-distance inductive sensor,

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

Aluminium-foil closures are commonly utilised as seals for

plastic containers filled with ketchup, mustard and other table

sauces. At a food-processing plant, closures are applied to

filled containers passing along an automated production line,

sealing the contents ready for capping and bulk packaging.

CUSTOMER APPLICATION

In the continuous production of fast-moving items, line

stoppages are both costly and time consuming. After filling,

sealing and capping, bottles of ketchups and sauces are

labelled and packaged. Previously, if a plastic cap was missing

it could go undetected, risking an entire batch of production

potentially being rejected.

Contrinex’s highly versatile photoelectric fork sensor, is

positioned directly over the conveyor to sense the presence of

a cap on each bottle prior to labelling, triggering an alarm if a

cap is missing.

PRODUCT ADVANTAGES

HIGH FREQUENCY UP TO 14 KHZ

4 SELECTABLE MODES BETWEEN PRODUCTION BATCHES:

STANDARD, HIGH RESOLUTION, POWER, SPEED

IO-LINK V1.1 COMMUNICATION PROTOCOL

SENSITIVITY ADJUSTMENT ALLOWING DETECTION OF

TRANSPARENT OBJECTS

PRECISE ALIGNMENT REQUIRES NO ON-SITE ADJUSTMENT