(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS Automation Limited®

HELPING YOU #MAKE SENSE OF SENSORS

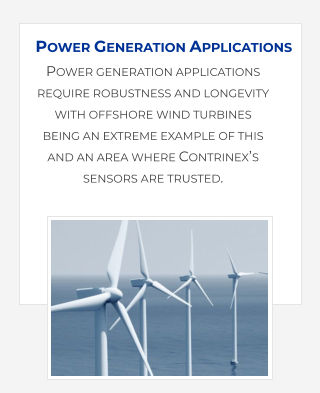

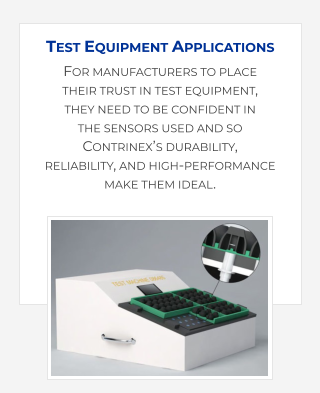

EXAMPLE APPLICATIONS

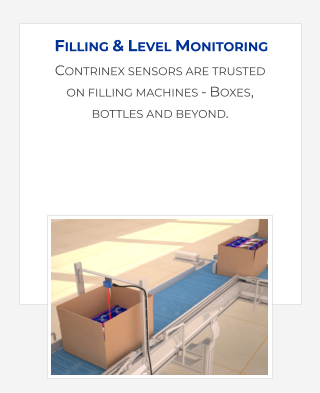

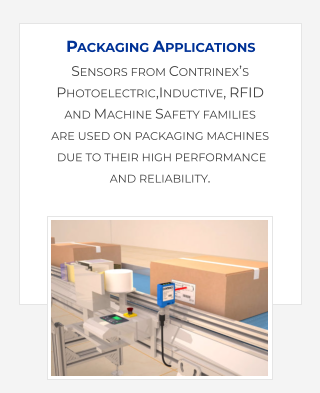

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

A sensing range up to 1200 mm, adjustable via a teach button

or via IO-Link, accommodates a wide range of machine

geometries. Sensitivity parameters are stored on the sensor’s

inbuilt memory and may be retrieved or updated remotely via

IO-Link, eliminating the need for manual adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention. The

solution is highly cost-effective with minimal non-productive

time; throughput is maintained at or above target levels.

I

CUSTOMER VALUES

SAFE DETECTION OF THE THINNEST TRANSPARENT MATERIALS

MAXIMUM OPERATING RESERVE OWING TO HIGH ABSORPTION

FACTOR OF UV LIGHT BY TRANSPARENT PLASTICS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

RELIABLE OPERATION WITHOUT THE NEED FOR MANUAL

INTERVENTION

VERY LOW SENSITIVITY TO DUST, LIQUID DROPLETS AND

SPLASHES

PRODUCT ADVANTAGES

REMOTE SENSITIVITY RETRIEVAL OR UPDATE VIA IO-LINK

IO-LINK SERIAL-CONNECTION PROTOCOL ENABLED ON PNP

VERSIONS AT NO ADDITIONAL COST

PRE-TAUGHT SENSITIVITY PARAMETERS STORED ON INBUILT

SENSOR MEMORY

HIGHLY TOLERANT OF CONTAMINATION BY DUST, LIQUID

DROPLETS OR SPLASHES

Clear plastic thermoformed tray bases are increasingly

commonly used in the packaging of a wide variety of products.

However, they pose a challenge for the high-speed automated

packaging leading Contrinex to develop a unique family. of

sensors.

Contrinex’s small C23PA transparent-object sensors with their

patented UV technology easily detect each set of transparent

trays after it is formed, initiating a subsequent operation and

triggering a counter. The Ecolab certification of these sensors

makes them ideally suited for the packaging of food and

medical products.

CUSTOMER APPLICATION

Clear plastic thermoformed blister-packs which in this

application are used to hold pharmaceutical and surgical

products typically comprise a recessed, semi-rigid tray base,

vacuum-formed in-line from clear thermoplastic material and

sealed with a metal or plastic film after the desired products

are loaded.

Typically, blister-packaging lines for surgical products operate

in sterile conditions where minimal manual intervention is

permitted, to minimise the risk of contamination. If defective

bases are identified and rejected after forming, the flow of tray

bases to the loading station is not continuous. In this event, a

sensor system must inhibit the loading cycle until a base is in

position.

Therefore, a sensor is required to detect the presence of

transparent tray bases swiftly and reliably, enabling the

loading cycle to proceed with minimal delay as soon as a tray

is present at the loading station. Standard photoelectric

sensors, which use visible red-light sources, proved to be

unreliable as they are unable to differentiate reliably between

‘tray present’ and ‘tray not present’ conditions.

An alternative sensor was sought that could reliably detect the

presence of a transparent plastic target.

CUSTOMER SOLUTION

The unique use of an ultraviolet light source in Contrinex’s

C23PA UV transparent-object detection sensors is ideal for this

application. Members of the miniature cubic C23PA sensor

family, these 20mm x 30mm x 10mm sensors are mounted

above the machine’s conveyors to detect the presence of

transparent tray bases as they arrive at the loading station.

Positioning sensors is simple thanks to a range of adjustable

mounting brackets, and their auto-collimated optics ensure

there are no blind zones.

The transparent-object sensors use a patented reflex operating

principle with polarised ultraviolet light with a 275 nm

wavelength. This wavelength is chosen because it is where the

absorption of the polarized UV light by a range of commonly

used plastics is maximised. A choice of size and shape of the

custom-designed UV reflectors which use high-tech plastic

materials with excellent reflective properties, simplifies

installation.

The customer makes use of both of the PNP normally-open

output and IO-Link, the standardised point-to-point serial

connection protocol for sensors and actuators, which is

included within the sensors for no additional cost.

An additional option across the C23PA family of photoelectric

sensors is to have a second switched output to provide a

‘stability alarm’ in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs. This provides extra functionality which is

simple to implement within the machine and at no additional

cost for the sensor.

The robust sensors feature Ecolab-certified plastic housings

and a sensing range up to 1200 mm, adjustable using a teach

button or IO-Link to accommodate a wide range of

applications. Sensitivity parameters are stored on the sensor’s

inbuilt memory and may be retrieved or updated remotely via

IO-Link, eliminating the need for manual adjustment.

The C23PA family of sensors also benefits from having a range

of complementary low-cost stainless-steel mounting and

protection bracketry options.

TRANSPARENT-OBJECT SENSORS WITH RED-LIGHT OR UNIQUE UV-LIGHT TECHNOLOGY

FOR RELIABLE DETECTION AND ACCURATE COUNTING OF CLEAR BOTTLES AND TRAYS -

SIMPLIFIED SET-UP & EXCEPTIONAL PERFORMANCE GIVE YOU A ‘CLEAR’ ADVANTAGE.

TRANSPARENT-OBJECT DETECTION SENSORS

I

CUSTOMER VALUES

UV SENSORS ENSURE RELIABLE DETECTION OF TRANSPARENT,

IRREGULARLY SHAPED PLASTIC TARGETS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

WIDE OPERATING RANGE ACCOMMODATES FULL RANGE OF

MACHINE GEOMETRIES

SIMPLE ONE- OR TWO-STEP TEACH PROCEDURE OPTIMISES

INITIAL SET-UP

SENSITIVITY PARAMETERS ARE RETRIEVED OR UPDATED

REMOTELY VIA IO-LINK

STABILITY ALARM HIGHLIGHTS REDUCED SENSITIVITY FOR

EXAMPLE FOR PREVENTATIVE MAINTENANCE

PRODUCT ADVANTAGES

ULTRAVIOLET REFLEX PHOTOELECTRIC SENSORS FOR

TRANSPARENT OBJECT DETECTION

VERY LOW SENSITIVITY TO TARGET SHAPE

ROBUST, ECOLAB APPROVED SENSORS WITH IP67-RATED

SMALL PLASTIC HOUSINGS

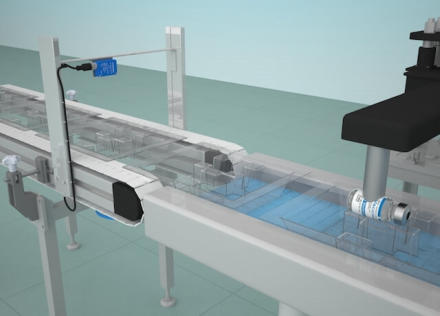

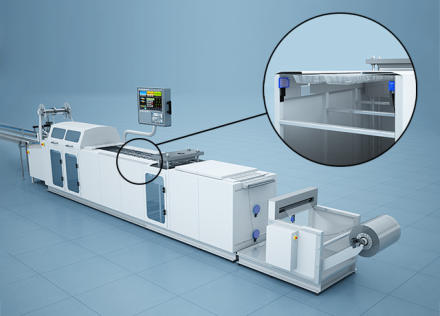

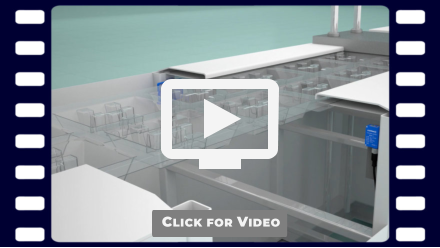

Thermoforming lines produce transparent plastic trays from

continuous reels of material. Contrinex’s transparent-object

sensors with patented UV technology are used to detect the

presence of the transparent plastic sheet as it is unwound

from the reel, ensuring the material is correctly tensioned as it

enters the loading station. False detection is avoided, ensuring

reliable operation with little or no downtime.

CUSTOMER APPLICATION

Thermoforming equipment is often used in the production of

plastic packaging and is particularly suitable for the

continuous production of blister-packs. The process involves

the in-line vacuum-forming of clear thermoplastic material

into semi-rigid blister-trays which, after insertion of the desired

products, are sealed with film. Configurable thermoforming

lines are ideal for the high-speed production of such blister-

trays from continuous reel-stock material.

Coupling a standalone reel-feeder to the loading station of a

modular line is quick and simple. In operation, a set of drive

rollers draws thermoplastic sheet from the stock reel, creating

a continuous loop of material between the feeder and the

loading station. Maintaining the size of the loop between

defined limits ensures the material is correctly tensioned as it

enters the loading station.

Sensors detect the presence of the transparent material as the

loop size varies, initiating or inhibiting operation of the feeder

if the loop becomes too small or too large, respectively.

Photoelectric sensors using visible-light sources are unreliable

in such an application as they cannot reliably differentiate

between ‘material present’ and ‘material not present’ under

normal operating conditions.

CUSTOMER SOLUTION

Contrinex C23 transparent-object reflex sensors with ultraviolet

LED-light sources are ideally suited to this application. These

miniature cubic devices, mounted between the reel feeder

and the loading station, detect the presence of the

transparent material loop as its size varies. Positioning the

sensors and reflectors is simple using a range of adjustable

mounting brackets, and auto-collimated optics which ensure

there are no blind zones.

Contrinex transparent-object sensors utilise a patented reflex

operating principle with polarised ultraviolet light at 275 nm.

At this wavelength, absorption of the polarised UV light by a

range of commonly used plastics is maximised. Custom-

designed UV reflectors, using high-tech plastic materials with

excellent reflective properties in the ultraviolet range, are

available in a range of sizes and geometries which simplify

installation.

An industry-standard PNP normally open output ensures

optimum flexibility. Additionally, IO-Link, a standardized point-

to-point serial connection protocol for sensors and actuators, is

enabled on PNP versions at no additional cost. An additional

option is to have a second output to provide the stability alarm

in the event of reduced sensitivity, flagging the need for

preventative maintenance before any performance

degradation occurs.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings, are corrosion-

resistant and impervious to water ingress and has the

additional benefit of offering a range of low-cost stainless-steel

mounting and protection bracketry.

The Contrinex TRU-C23 photoelectric sensor is ideally suited for the presence control of transparent objects. Its patented

technology uses UV light. Since transparent materials like plastic or glass absorb large amounts of polarized UV light, it is very easy

to set the threshold at which the sensor switches. This makes commissioning much easier. The shape or thickness of the target has

no influence on detection. In addition, sensor performance is unaffected by dirt, water drops or aging. Multiple switching for the

same object is eliminated.

The sensor system comprises an LED that emits polarized UV light and a reflector made of special materials suitable for UV. Overall,

the sensor’s operating range is around 1200 mm. Special optics with auto-collimation ensure reliable detection and no blind zone,

even close to the sensor or through a small notch.

For applications requiring the detection of thicker or larger transparent objects, the C23 Transparent Standard can be the ideal

solution. It operates with polarized, red light and has a maximum operating range up to 5000 mm. This sensor provides a highly

favourable price-performance ratio. Typical fields of application can be found in the food, pharmaceutical and packaging industries,

for example when filling glass or plastic bottles, packing in plastic or when the detection of clear packaging film is required.

The housing, which for both types measures only 30 x 20 x 10 mm, is compatible with the entire C23 series as well as comparable

devices. The IO-Link interface also provides the important additional benefit of remote commissioning, diagnostics and

parameterisation as standard and at no extra cost. Sensors are Ecolab tested and approved, rated to IP67 and reliably withstand

common industrial cleaning processes.

PRODUCT ADVANTAGES

CHOICE OF RED OR ULTRAVIOLET LIGHT ENSURE RELIABLE

DETECTION OF TRANSPARENT, IRREGULARLY SHAPED TARGETS

REFLEX PHOTOELECTRIC TRANSPARENT OBJECT DETECTION

ULTRAVIOLET LIGHT ELIMINATES MULTIPLE SWITCHING ON A

SINGLE TARGET - VERY LOW SENSITIVITY TO TARGET SHAPE

WIDE OPERATING RANGE ACCOMMODATES FULL RANGE OF

MACHINE GEOMETRIES

SIMPLE 1 OR 2-STEP TEACH OPTIMISES INITIAL SET-UP

SENSITIVITY PARAMETERS CAN BE RETRIEVED OR UPDATED

REMOTELY VIA IO-LINK

STABILITY ALARM HIGHLIGHTS REDUCED SENSITIVITY FOR

EXAMPLE FOR PREVENTATIVE MAINTENANCE

ROBUST, ECOLAB APPROVED SENSORS WITH IP67-RATED

SMALL PLASTIC HOUSINGS

TRANSPARENT-OBJECT DETECTION SENSORS - A ‘CLEAR’ ADVANTAGE.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

VIDEOS, READ APPLICATION EXAMPLES BELOW,

CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP GUIDE

YOU THROUGH SELECTION, ANSWER QUESTIONS,

OR TO HELP YOU #MAKESENSEOFSENSORS:

TRANSPARENT-OBJECT

DETECTION SENSORS

TRANSPARENT-OBJECT SENSORS WITH

RED-LIGHT OR UNIQUE UV-LIGHT TECHNOLOGY

FOR RELIABLE DETECTION AND ACCURATE

COUNTING OF CLEAR BOTTLES AND TRAYS -

SIMPLIFIED SET-UP & EXCEPTIONAL

PERFORMANCE GIVE YOU A ‘CLEAR’ ADVANTAGE.

Thermoforming lines produce transparent plastic trays from

continuous reels of material. Contrinex’s transparent-object

sensors with patented UV technology are used to detect the

presence of the transparent plastic sheet as it is unwound

from the reel, ensuring the material is correctly tensioned as it

enters the loading station. False detection is avoided, ensuring

reliable operation with little or no downtime.

CUSTOMER APPLICATION

Thermoforming equipment is often used in the production of

plastic packaging and is particularly suitable for the

continuous production of blister-packs. The process involves

the in-line vacuum-forming of clear thermoplastic material

into semi-rigid blister-trays which, after insertion of the desired

products, are sealed with film. Configurable thermoforming

lines are ideal for the high-speed production of such blister-

trays from continuous reel-stock material.

Coupling a standalone reel-feeder to the loading station of a

modular line is quick and simple. In operation, a set of drive

rollers draws thermoplastic sheet from the stock reel, creating

a continuous loop of material between the feeder and the

loading station. Maintaining the size of the loop between

defined limits ensures the material is correctly tensioned as it

enters the loading station.

Sensors detect the presence of the transparent material as the

loop size varies, initiating or inhibiting operation of the feeder

if the loop becomes too small or too large, respectively.

Photoelectric sensors using visible-light sources are unreliable

in such an application as they cannot reliably differentiate

between ‘material present’ and ‘material not present’ under

normal operating conditions.

CUSTOMER SOLUTION

Contrinex C23 transparent-object reflex sensors with ultraviolet

LED-light sources are ideally suited to this application. These

miniature cubic devices, mounted between the reel feeder

and the loading station, detect the presence of the

transparent material loop as its size varies. Positioning the

sensors and reflectors is simple using a range of adjustable

mounting brackets, and auto-collimated optics which ensure

there are no blind zones.

Contrinex transparent-object sensors utilise a patented reflex

operating principle with polarised ultraviolet light at 275 nm.

At this wavelength, absorption of the polarised UV light by a

range of commonly used plastics is maximised. Custom-

designed UV reflectors, using high-tech plastic materials with

excellent reflective properties in the ultraviolet range, are

available in a range of sizes and geometries which simplify

installation.

An industry-standard PNP normally open output ensures

optimum flexibility. Additionally, IO-Link, a standardized point-

to-point serial connection protocol for sensors and actuators, is

enabled on PNP versions at no additional cost. An additional

option is to have a second output to provide the stability alarm

in the event of reduced sensitivity, flagging the need for

preventative maintenance before any performance

degradation occurs.

The robust sensors which are only 20mm x 30mm x 10mm

feature Ecolab-certified plastic housings, are corrosion-

resistant and impervious to water ingress and has the

additional benefit of offering a range of low-cost stainless-steel

mounting and protection bracketry.

CUSTOMER VALUES

UV SENSORS ENSURE RELIABLE DETECTION OF TRANSPARENT,

IRREGULARLY SHAPED PLASTIC TARGETS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

WIDE OPERATING RANGE ACCOMMODATES FULL RANGE OF

MACHINE GEOMETRIES

SIMPLE ONE- OR TWO-STEP TEACH PROCEDURE OPTIMISES

INITIAL SET-UP

SENSITIVITY PARAMETERS ARE RETRIEVED OR UPDATED

REMOTELY VIA IO-LINK

STABILITY ALARM HIGHLIGHTS REDUCED SENSITIVITY FOR

EXAMPLE FOR PREVENTATIVE MAINTENANCE

PRODUCT ADVANTAGES

ULTRAVIOLET REFLEX PHOTOELECTRIC SENSORS FOR

TRANSPARENT OBJECT DETECTION

VERY LOW SENSITIVITY TO TARGET SHAPE

ROBUST, ECOLAB APPROVED SENSORS WITH IP67-RATED

SMALL PLASTIC HOUSINGS

Clear plastic thermoformed tray bases are increasingly

commonly used in the packaging of a wide variety of products.

However, they pose a challenge for the high-speed automated

packaging leading Contrinex to develop a unique family. of

sensors.

Contrinex’s small C23PA transparent-object sensors with their

patented UV technology easily detect each set of transparent

trays after it is formed, initiating a subsequent operation and

triggering a counter. The Ecolab certification of these sensors

makes them ideally suited for the packaging of food and

medical products.

CUSTOMER APPLICATION

Clear plastic thermoformed blister-packs which in this

application are used to hold pharmaceutical and surgical

products typically comprise a recessed, semi-rigid tray base,

vacuum-formed in-line from clear thermoplastic material and

sealed with a metal or plastic film after the desired products

are loaded.

Typically, blister-packaging lines for surgical products operate

in sterile conditions where minimal manual intervention is

permitted, to minimise the risk of contamination. If defective

bases are identified and rejected after forming, the flow of tray

bases to the loading station is not continuous. In this event, a

sensor system must inhibit the loading cycle until a base is in

position.

Therefore, a sensor is required to detect the presence of

transparent tray bases swiftly and reliably, enabling the

loading cycle to proceed with minimal delay as soon as a tray

is present at the loading station. Standard photoelectric

sensors, which use visible red-light sources, proved to be

unreliable as they are unable to differentiate reliably between

‘tray present’ and ‘tray not present’ conditions.

An alternative sensor was sought that could reliably detect the

presence of a transparent plastic target.

CUSTOMER SOLUTION

The unique use of an ultraviolet light source in Contrinex’s

C23PA UV transparent-object detection sensors is ideal for this

application. Members of the miniature cubic C23PA sensor

family, these 20mm x 30mm x 10mm sensors are mounted

above the machine’s conveyors to detect the presence of

transparent tray bases as they arrive at the loading station.

Positioning sensors is simple thanks to a range of adjustable

mounting brackets, and their auto-collimated optics ensure

there are no blind zones.

The transparent-object sensors use a patented reflex operating

principle with polarised ultraviolet light with a 275 nm

wavelength. This wavelength is chosen because it is where the

absorption of the polarized UV light by a range of commonly

used plastics is maximised. A choice of size and shape of the

custom-designed UV reflectors which use high-tech plastic

materials with excellent reflective properties, simplifies

installation.

The customer makes use of both of the PNP normally-open

output and IO-Link, the standardised point-to-point serial

connection protocol for sensors and actuators, which is

included within the sensors for no additional cost.

An additional option across the C23PA family of photoelectric

sensors is to have a second switched output to provide a

‘stability alarm’ in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs. This provides extra functionality which is

simple to implement within the machine and at no additional

cost for the sensor.

The robust sensors feature Ecolab-certified plastic housings

and a sensing range up to 1200 mm, adjustable using a teach

button or IO-Link to accommodate a wide range of

applications. Sensitivity parameters are stored on the sensor’s

inbuilt memory and may be retrieved or updated remotely via

IO-Link, eliminating the need for manual adjustment.

The C23PA family of sensors also benefits from having a range

of complementary low-cost stainless-steel mounting and

protection bracketry options.

CUSTOMER VALUES

SAFE DETECTION OF THE THINNEST TRANSPARENT MATERIALS

MAXIMUM OPERATING RESERVE OWING TO HIGH ABSORPTION

FACTOR OF UV LIGHT BY TRANSPARENT PLASTICS

ELIMINATION OF MULTIPLE SWITCHING ON A SINGLE TARGET

RELIABLE OPERATION WITHOUT THE NEED FOR MANUAL

INTERVENTION

VERY LOW SENSITIVITY TO DUST, LIQUID DROPLETS AND

SPLASHES

PRODUCT ADVANTAGES

REMOTE SENSITIVITY RETRIEVAL OR UPDATE VIA IO-LINK

IO-LINK SERIAL-CONNECTION PROTOCOL ENABLED ON PNP

VERSIONS AT NO ADDITIONAL COST

PRE-TAUGHT SENSITIVITY PARAMETERS STORED ON INBUILT

SENSOR MEMORY

HIGHLY TOLERANT OF CONTAMINATION BY DUST, LIQUID

DROPLETS OR SPLASHES

A sensing range up to 1200 mm, adjustable via a teach button

or via IO-Link, accommodates a wide range of machine

geometries. Sensitivity parameters are stored on the sensor’s

inbuilt memory and may be retrieved or updated remotely via

IO-Link, eliminating the need for manual adjustment.

These rugged miniature sensors meet the customer’s need for

reliable operation with little or no manual intervention. The

solution is highly cost-effective with minimal non-productive

time; throughput is maintained at or above target levels.

TRANSPARENT-OBJECT DETECTION

SENSORS - A ‘CLEAR’ ADVANTAGE.

The Contrinex TRU-C23 photoelectric sensor is ideally suited for

the presence control of transparent objects. Its patented

technology uses UV light. Since transparent materials like

plastic or glass absorb large amounts of polarized UV light, it is

very easy to set the threshold at which the sensor switches.

This makes commissioning much easier. The shape or

thickness of the target has no influence on detection. In

addition, sensor performance is unaffected by dirt, water drops

or aging. Multiple switching for the same object is eliminated.

The sensor system comprises an LED that emits polarized UV

light and a reflector made of special materials suitable for UV.

Overall, the sensor’s operating range is around 1200 mm.

Special optics with auto-collimation ensure reliable detection

and no blind zone, even close to the sensor or through a small

notch.

For applications requiring the detection of thicker or larger

transparent objects, the C23 Transparent Standard can be the

ideal solution. It operates with polarized, red light and has a

maximum operating range up to 5000 mm. This sensor

provides a highly favourable price-performance ratio. Typical

fields of application can be found in the food, pharmaceutical

and packaging industries, for example when filling glass or

plastic bottles, packing in plastic or when the detection of clear

packaging film is required.

The housing, which for both types measures only 30 x 20 x 10

mm, is compatible with the entire C23 series as well as

comparable devices. The IO-Link interface also provides the

important additional benefit of remote commissioning,

diagnostics and parameterisation as standard and at no extra

cost. Sensors are Ecolab tested and approved, rated to IP67 and

reliably withstand common industrial cleaning processes.

PRODUCT ADVANTAGES

CHOICE OF RED OR ULTRAVIOLET LIGHT ENSURE RELIABLE

DETECTION OF TRANSPARENT, IRREGULARLY SHAPED TARGETS

REFLEX PHOTOELECTRIC TRANSPARENT OBJECT DETECTION

ULTRAVIOLET LIGHT ELIMINATES MULTIPLE SWITCHING ON A

SINGLE TARGET - VERY LOW SENSITIVITY TO TARGET SHAPE

WIDE OPERATING RANGE ACCOMMODATES FULL RANGE OF

MACHINE GEOMETRIES

SIMPLE 1 OR 2-STEP TEACH OPTIMISES INITIAL SET-UP

SENSITIVITY PARAMETERS CAN BE RETRIEVED OR UPDATED

REMOTELY VIA IO-LINK

STABILITY ALARM HIGHLIGHTS REDUCED SENSITIVITY FOR

EXAMPLE FOR PREVENTATIVE MAINTENANCE

ROBUST, ECOLAB APPROVED SENSORS WITH IP67-RATED

SMALL PLASTIC HOUSINGS

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS