(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

PRODUCT ADVANTAGES

ACTIVSTONE™ COATING ON ALL EXTERNAL SURFACES RESISTS

WELD SPATTER IN SPOT, MIG AND MAG APPLICATIONS

CONTRINEX SENSORS RESIST MAGNETIC INTERFERENCE FROM

MEDIUM-FREQUENCY WELD FIELDS, CURRENT UP TO 15 KA

WITH ONE-PIECE STAINLESS-STEEL HOUSINGS AND CONDET®

TECHNOLOGY, FULL INOX SENSORS OFFER MAXIMUM IMPACT

RESISTANCE

ACTIVSTONE™ COATED MOUNTING BRACKETS AND SPATTER-

RESISTANT CABLE

EXCEPTIONALLY ROBUST WELD-IMMUNE INDUCTIVE SENSORS - NOW WITH CERAMIC-COATING OPTION

THE INNOVATIVE 700 SERIES INDUCTIVE SENSOR FAMILY, ALSO INCLUDES ‘WELD-IMMUNE’

VERSIONS. RFI RESISTANCE AND THE OPTION OF A CERAMIC COATING IS ADDED TO THE UNIQUE

IMPACT AND ABRASION RESISTANCE - IMAGINE HOW THEY CAN REDUCE MACHINE DOWN-TIME.

WELD-IMMUNE 700 SERIES INDUCTIVE SENSORS

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

Contrinex’s weld-Immune range of inductive sensors now includes the option of an ACTIVSTONE™ ceramic-coating for the highest

level of weld spatter resistance. The high-performance ceramic material forms a durable, non-stick coating on all external surfaces

of the sensor, including the fixing nuts. By preventing weld spatter accumulation, this coating makes slag removal much easier and

reduces maintenance costs.

All Contrinex Weld-Immune sensors combine optimum detection sensitivity with immunity to magnetic interference, in particular

from medium-frequency weld fields (current up to 15 kA). They are ideal for the hostile working environments found in automotive

factories and other industrial welding plants.

Sensors from the Full Stainless-steel family are recommended for long service life in the most demanding welding environments. A

sealed, one-piece housing in V2A/AISI 303 stainless steel provides excellent chemical and mechanical resistance to shocks, vibration

and abrasion. Best-in-class sensing ranges of up to 16 mm eliminate the risk of collision damage – a frequent occurrence when

operating in close proximity to moving machine parts. In addition, sensors are unaffected by weld spatter, metal dust or chips and

offer long operating distances with factor 1 on steel and aluminium.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

VIDEOS BELOW, CLICK HERE TO VIEW THIS

SENSOR ON CONTRINEX’S WEBSITE, OR CALL US

TO HELP GUIDE YOU THROUGH SELECTION,

ANSWER QUESTIONS, OR TO HELP YOU

#MAKESENSEOFSENSORS:

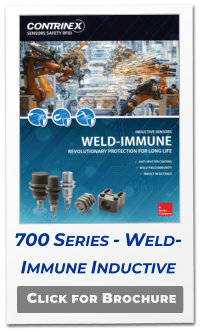

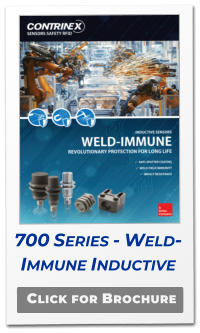

700 SERIES -

WELD-IMMUNE INDUCTIVES

THE INNOVATIVE 700 SERIES INDUCTIVE SENSOR

FAMILY, ALSO INCLUDES ‘WELD-IMMUNE’ VERSIONS.

RFI RESISTANCE AND THE OPTION OF A CERAMIC

COATING IS ADDED TO THE UNIQUE IMPACT AND

ABRASION RESISTANCE - IMAGINE HOW THEY CAN

REDUCE MACHINE DOWN-TIME.

PRODUCT ADVANTAGES

ACTIVSTONE™ COATING ON ALL EXTERNAL SURFACES RESISTS

WELD SPATTER IN SPOT, MIG AND MAG APPLICATIONS

CONTRINEX SENSORS RESIST MAGNETIC INTERFERENCE FROM

MEDIUM-FREQUENCY WELD FIELDS, CURRENT UP TO 15 KA

WITH ONE-PIECE STAINLESS-STEEL HOUSINGS AND CONDET®

TECHNOLOGY, FULL INOX SENSORS OFFER MAXIMUM IMPACT

RESISTANCE

ACTIVSTONE™ COATED MOUNTING BRACKETS AND SPATTER-

RESISTANT CABLE

Contrinex’s weld-Immune range of inductive sensors now

includes the option of an ACTIVSTONE™ ceramic-coating for

the highest level of weld spatter resistance. The high-

performance ceramic material forms a durable, non-stick

coating on all external surfaces of the sensor, including the

fixing nuts. By preventing weld spatter accumulation, this

coating makes slag removal much easier and reduces

maintenance costs.

All Contrinex Weld-Immune sensors combine optimum

detection sensitivity with immunity to magnetic interference,

in particular from medium-frequency weld fields (current up to

15kA). They are ideal for the hostile working environments

found in automotive factories and other industrial welding

plants.

EXCEPTIONALLY ROBUST WELD-IMMUNE INDUCTIVE

SENSORS - NOW WITH CERAMIC-COATING OPTION

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

Sensors from the Full stainless-steel family are recommended

for long service life in the most demanding welding

environments. A sealed, one-piece housing in V2A/AISI 303

stainless steel provides excellent chemical and mechanical

resistance to shocks, vibration and abrasion. Best-in-class

sensing ranges of up to 16 mm eliminate the risk of collision

damage – a frequent occurrence when operating in close

proximity to moving machine parts. In addition, sensors are

unaffected by weld spatter, metal dust or chips and offer long

operating distances with factor 1 on steel and aluminium.

Weld-Immune inductive sensors from Contrinex with

ACTIVSTONE™ coating offer the highest level of weld spatter

resistance. The high-performance ceramic material forms a

durable, non-stick coating on all external surfaces of the sensor,

including the fixing nuts. The coating material prevents weld

spatter accumulation, making slag removal much easier and

reducing maintenance costs. As a sensor coating, it provides

excellent, long-term protection in spot, MIG and MAG

applications.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS