(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

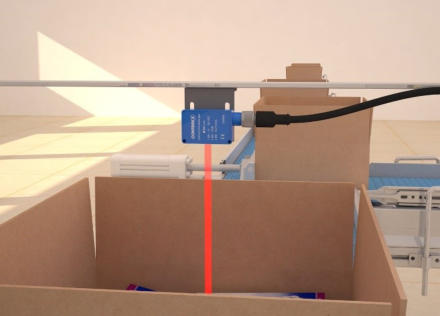

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP versions

CUSTOMER VALUES

NON-CONTACT SENSING

MOUNTING OUT OF HARM’S WAY

RELATIVELY TAMPER PROOF

PRODUCT ADVANTAGES

CHOICE OF CUBIC C23PA OR CYLINDRICAL M18MA BODIES

SMALL SIZE - 20 x 30 x 10mm or Ø18 x 37mm

SENSING RANGE UP TO 300MM / 250MM RESPECTIVELY

EASY ADJUSTMENT DUE TO VISIBLE BEAM

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

Cotton spinning machines use a robotic vacuum cleaning

system to prevent lint build-up on machinery and product. To

ensure the vacuum cleaning robot does not collide with the

spinning machine, a Contrinex Background Suppression

photoelectric sensor detects their presence.

CUSTOMER APPLICATION

Lint is generated from the process of spinning cotton and if

lint is allowed to accumulate, it will eventually clog the small

eyelets and guides on the spinning machine.

Because a build-up of lint can cause yarn breakage, spinning

machinery is equipped with vacuum systems that constantly

rove the machine to collect lint. These systems depend on a

relatively slow-moving vacuum head, which travels on a rail

mounted above.

The spinning machines are tended by operators who might

accidentally leave items in the path of the vacuum head. To

prevent collisions with these objects, the existing detection

system on the vacuum head consists of a limit switch with a

mechanical wand attachment. As soon as the wand touched

an obstacle, it caused the vacuum head to reverse its direction

of travel, but the customer wanted to upgrade to a non-

contact detection solution more suited to an automated

environment.

CUSTOMER SOLUTION

Contrinex’s LHR-C23PA cubic and LHR-M18PA background

suppression photoelectric sensors are ideal for this application.

Despite their small size (20 x 30 x 10mm or Ø18 x 37mm), these

sensors are both robust and high-performance offering a

sensing range of 300 or 250mm respectively.

The sensor’s precise background suppression enables them to

detect the presence of any obstacle regardless of colour,

brightness or angle in relation to the position of the sensor on

the vacuum head.

The LHR-C23PA cubic sensor is mounted on the vacuum head

to provide sensing for the robotic system’s safety reversal

function. The operating range can be adjusted to detect an

obstacle between 15 to 250 mm away, in which case the

cleaning machine simply reverses its direction of travel,

without interrupting the cleaning function.

C23 20 X 30 X 10MM

CUSTOMER VALUES

ECONOMICAL, FAST AND ABSOLUTELY RELIABLE

NON-CONTACT OPERATION, TO AVOID MECHANICAL WEAR

EXCELLENT PERFORMANCE COMBINED WITH SMALL SIZE

LONG SERVICE LIFE

SENSORS READY MADE-UP AND EASY TO USE

FLEXIBILITY OF SOLUTION

PRODUCT ADVANTAGES

LARGE OPERATING DISTANCE AND SIGNAL RESOLUTION

PROTECTION CLASS IP 67

OUTSTANDING PERFORMANCE ON DETECTION

ACCURACY, SPEED AND FREQUENCY

Contrinex Standard photoelectric sensors are ideal for general position and presence-detection for almost any industry and

application. Best-in-class performance such as sensing ranges and background suppression characteristics, the Standard range of

sensors delivers very high accuracy and reliability.

A wide variety of housing designs and sizes are offered::

•

Cubic sizes: 0507 (5 x 7 x 40mm), C12 (13 x 21 x 7mm), C23 (20 x 30 x 10mm), 3030 (30 x 30 x 15mm), 4040 (40 x 40 x 19mm),

4050 (40 x 50 x 15mm) and C55 (50 x 50 x 23mm).

•

Cylindrical types are also available in sizes M12 and M18.

STANDARD PHOTOELECTRIC SENSORS - EXCELLENCE IN PRICE & PERFORMANCE.

Standard C23 and M18P series are high quality ASIC sensors with an integral IO-Link interface in PNP types. This makes them

particularly suitable for smart factory applications. IO-Link extends sensor functionality to include continuous monitoring of

process data, continuous diagnosis of sensor status, advanced parameter settings, sensitivity adjustment, a remote teach function

and easy checking of sensor ID, to ensure the right sensor is at the right place.

TECHNOLOGY

Diffuse

A diffuse-mode, or energetic-diffuse, photoelectric sensor is a reflective sensor, containing a transmitter and a receiver in a single

housing. The sensor emits a focused light beam toward a distant target that acts as a reflector, returning part of the transmitted

light to the sensor. The receiver detects the amount of light reflected by the target, triggering the sensor when the light intensity

reaches a threshold value.

•

Ideal for short sensing ranges and relatively easy targets

•

Easy installation and alignment

•

No separate reflector or receiver

Background-Suppression

Diffuse-mode photoelectric sensors with background suppression emit a focused light beam toward a distant target. Part of the

beam is reflected from the target and returns to the sensor, striking a position-sensitive receiver. The receiver distinguishes

between reflections from the target and reflections from background objects, only triggering the sensor when the signal reaches a

value that corresponds to the preset target distance.

•

Target size, colour, shape and surface finish have little influence on sensing range

•

Suitable for difficult targets (small, fast-moving, light background)

•

No separate reflector or receiver”

Reflex

A reflex, or reflective, photoelectric sensor contains a transmitter and a receiver in a single housing, and emits a pulsed, focused

light beam through a polarisation filter toward a distant reflector. Reflected light returns to the sensor, passing through a second

filter before arriving at the receiver. When a target object interrupts the light beam, the receiver detects the reduced light intensity

and triggers the sensor. Auto-collimation of the light beam allows blind-zone suppression.

•

Ideal for moderate sensing ranges

•

Wiring required for just one emitter/receiver unit

•

Separately mounted reflector

Through-beam

Contrinex through-beam photoelectric sensors are ideal for industrial applications where sensing components must be mounted

some distance from the target area. Through-beam sensors utilise infra-red, visible and laser light sources to detect targets, reliably

and repeatably, at extended distances.

•

Ideal for long sensing ranges

•

Suitable for contaminated environments or highly reflective targets

•

Separately mounted and wired receiver

CUSTOMER VALUES

RELIABLE CHECK OF ASSEMBLY TO AVOID CUSTOMER

REJECTIONS

RECORDABLE CONFIRMATION OF GEAR MODEL

PRODUCT ADVANTAGES

RUGGED LASER SENSOR WITH METAL HOUSING

SENSING RANGE UP TO 250MM

BUILT-IN CHANGEOVER OUTPUTS

EASY ADJUSTMENT DUE TO VISIBLE BEAM

ADJUSTABLE FOCUS OF BEAM

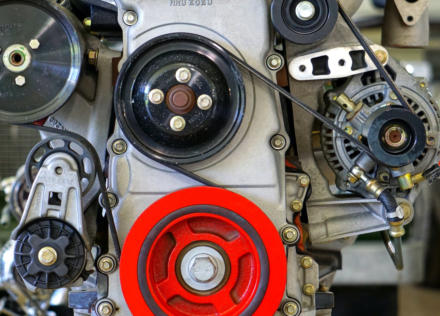

A manufacturer of assembled, forged and machined

components for the automotive industry trusts Contrinex

distance sensing photoelectric sensors to ensure that the

correct gear model is selected in an assembly.

CUSTOMER APPLICATION

Because the manufacturer has two models of gears, both of

which are designed to fit into the same location in the

assembly, care must be taken over which version is being

produced.

During the production process for each specific assembly,

confirmation is required that the correct gear model has been

mounted. This is achieved by verifying the assembly as a

whole. Since the height of the assembled component differs

depending on which gear model has been mounted,

immediate identification of assembly height is the chosen

sensing solution. Space is limited, so a compact sensor with a

long sensing range is required.

CUSTOMER SOLUTION

Contrinex’s LTS-1180L-103 compact M18 photoelectric laser

sensors is ideal for this application. Its compact size, easy

adjustment and rugged metal housing make it suitable for

this tough industrial environment.

The mounted assembly has a curved section at the top. The

sensor’s task is to detect the highest point of this curved

section and verify the height of the finished component. The

small beam spot of this laser sensor is therefore essential. By

targeting the beam of sensor on this curved part, when the

correct gear is in place the beam will be deflected and the

sensor will not trigger the output. However, if the wrong part is

mounted, i.e. with more height, it will obstruct the sensor

beam and trigger the sensor output. By using a sensor with

integral changeover outputs, the same sensor can be used to

verify both models. Only one selection switch is required.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE POSITION SENSING ON A NON-

CONTACT BASIS

IMPROVED THROUGHPUT ARISING FROM REAL-TIME

DETECTION OF INCORRECTLY POSITIONED OR MISSING

CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS

SINGLE SENSOR ACCOMMODATES A RANGE OF CARTON SIZES

WITHOUT REPOSITIONING

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 8000MM WITH 78MM-

DIAMETER REFLECTOR

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

During confectionery packaging operations, conveyor lines

deliver preformed cardboard cartons to packing stations. At

each station, a pick-and-place packing robot packs layers of

bagged candy in cartons. Once filled, cartons are conveyed to

case-sealing stations. A highly reliable retro-reflex

photoelectric sensor, mounted beside the line, senses each

carton as it arrives at the packing station, halting the conveyor

and initiating the packing sequence once it is correctly

positioned.

CUSTOMER APPLICATION

In the confectionery-manufacturing industry, secondary

packaging is usually required when preparing multiple

product packs for wholesale distribution. In high-volume

production, manufacturers pack sealed bags of candy in

cardboard cartons, which are in turn stacked for shrink-

wrapping and palletisation.

Preformed cartons arrive at the packing station in a

continuous stream. Once the leading carton reaches its

designated position, the conveyor halts and the packing

sequence commences. A pick-and-place robot lifts successive

layers of bags and lowers them into the carton. Once the

predetermined number of bags has been packed, the carton is

conveyed to a sealing station.

If a carton stops in the wrong position, or if no carton is

present, the packing sequence must be inhibited to prevent

damage occurring. A non-contact sensor system is needed to

detect the position of the leading carton as it arrives at the

packing station, halting the conveyor and initiating the

packing sequence once. It must be reliable and require

minimal maintenance.

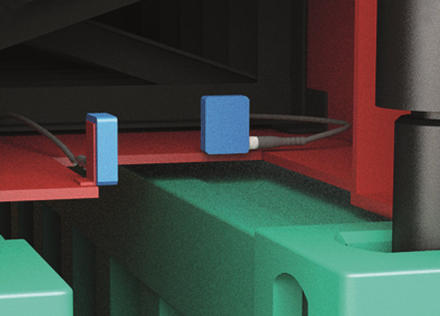

CUSTOMER SOLUTION

Miniature retro-reflex photoelectric sensors from the Contrinex

C23 range are ideal for this application. Used in conjunction

with a 41mm-diameter reflector, these sensors have an

operating range of up to 4500mm – more than adequate for

the task. A single sensor is mounted beside the carton

conveyor, immediately before the packing station, with the

reflector positioned on the opposite side. As the leading carton

breaks the light beam, the sensor detects its presence and

halts the conveyor in the correct position for packing.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

A custom-designed range of multi-position mounting

brackets allows systems engineers to locate sensors optimally

in almost any situation. The C23 range detects slow- or fast-

moving targets reliably. Remote selection of switching

frequency is possible via IO-Link, a standardized point-to-point

serial connection protocol, available as standard at no extra

cost for PNP versions.

A manufacturer of automated laboratory equipment for in-

vitro diagnostics trusts the long operating distance and high

resolution of Contrinex’s reflex photoelectric sensors to detect

the if a cap is fitted on a blood testing vial which is a small

glass test-tube.

CUSTOMER APPLICATION

To automate the placement of the small test-tubes into carrier

racks, a machine picks test-tubes from a conveyor. It is

essential that the vials are pushed into the carrier racks the

right way up, with the cap uppermost. The challenge is that

whilst the test tubes are aligned parallel to each other on the

feed conveyor, they can be positioned with the orientation of

the tube having the cap to the right, or to the left.

The shape and material of the test-tubes makes measuring

them difficult because they are round, transparent and filled

with liquid in varying quantities, with indistinct contours and a

lack of planar surfaces. Camera-based identification systems

or profile scanners were considered to be too expensive.

Additionally , the customer needed a quick solution that was

reliable as well as economic.

CUSTOMER SOLUTION

Test-tubes lying on the conveyor pass under a lightweight

lever which traces the contour of the test-tube, rising or falling

accordingly. The side of the lever facing the photoelectric

sensor provides a planer surface, guaranteeing absolutely

reliable measurement.

The sensor can detect the fitted cap because it has a 2mm

larger diameter than the test tube. Therefore, the machine’s

controller polls the sensor every 20 ms, and uses its analogue

value to determine the position of the larger cap

mathematically. According to this measurement, the machine

then turns the test-tube the right way up and pushes it into

the rack. A test-tube without a cap is identified by the sensor

as an error, since no significant difference can be detected and

the machine stops running. The automation enables one test-

tube to be inserted every second and ensures their correct

orientation.

CONTRINEX’S PHOTOELECTRIC SENSORS EXCEL AT POSITIONING AND PRESENCE-DETECTION -

FOR EXAMPLE HIGH-PERFORMANCE, INDUSTRY LEADING SENSING DISTANCES AND OUTSTANDING

BACKGROUND SUPPRESSION CHARACTERISTICS, COMBINE TO GIVE HIGH ACCURACY AND RELIABILITY.

STANDARD PHOTOELECTRIC SENSORS

CUSTOMER VALUES

NON-CONTACT, ALL-ELECTRONIC DEVICE WITH SENSING

RANGE UP TO 500MM.

LARGE SENSING RANGE AVAILABLE IN A PHYSICALLY SMALL

SENSOR.• EXCEPTIONAL RESISTANCE TO EXTREME VIBRATION

DURING OPERATION.

OPTIMAL SPACE UTILISATION WITH LITTLE OR NO RELIANCE

ON OPERATOR INVOLVEMENT

PRODUCT ADVANTAGES

ELIMINATION OF CALIBRATION ERRORS DURING NORMAL

OPERATION

LARGE SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

PROVIDES RELIABLE, REPEATABLE SENSING IN DEMANDING

OPERATING CONDITIONS

At busy container seaports, purpose-designed container-

handling vehicles called Straddle Carriers, operate around the

clock, loading, unloading and stacking containers. Space

utilisation is increasingly important and correctly identifying

the size of container picked for each lift is essential for

efficiency.

Contrinex photoelectric sensors have been fitted to the

Straddle Carriers to detect the container size and eliminate the

need for drivers to carry out identification checks, saving time

and avoiding errors.

CUSTOMER APPLICATION

A fleet of straddle carriers, purpose-designed container-

handling vehicles, services a busy French container port. As a

straddle carrier moves over a container, a central lifting beam

lowers and locks onto the corner castings of the container;

each lift comprises either a single 40-foot container or two 20-

foot containers.

Optimal utilisation of storage space is essential; correctly

identifying the size of container picked for each lift is vital.

Fitting carriers with sensors that detect the size and type of

containers at the time of lifting eliminate the need for drivers

to carry out identification checks, saving time and avoiding

errors.

The original mechanical sensors proved unreliable, losing

calibration when subjected to continuous vibration during

normal operation. Although the scheduled maintenance

interval for each vehicle is 1,000 hours, mechanical sensors

required recalibration at intervals of no more than two or three

days. A highly stable replacement sensor system was required.

CUSTOMER SOLUTION

Highly stable, non-contact, all-electronic units from the

Contrinex range of photoelectric sensors provide a reliable and

cost-effective alternative. The moulded-resin sensor casings,

fitted with coated-plastic sensing faces, are IP67 rated, making

them virtually impervious to the harsh, salt-laden environment

of a busy container port. Connection to the vehicle’s control

systems is via an integral M12 connector and PVC-sheathed

cable, allowing easy removal and replacement during routine

maintenance.

To confirm the size of the container, two pairs of diffuse

sensors with background suppression are mounted centrally

on each lifting beam. As the lifting beam descends, one sensor

from each pair detects the presence or absence of corner

castings at the central lifting points, while the other detects

the presence or absence of the gap between two 20-foot

containers. The combination of the two eliminates incorrect

identification in the unlikely event that the first sensor returns

a false-positive signal from a 40-foot container.

A physically small housing and long sensing distances

eliminate the risk of accidental damage arising from a

mechanical collision, while rugged industry-standard housings

and vacuum-encapsulated electronics minimise the effects of

vibration.

Operational results have been excellent; the new Contrinex

sensors have eliminated calibration errors and reduced

maintenance costs significantly.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

(0121) 58 222 58

SALES@PLUSAUTOMATION.CO.UK

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE QUALITY CHECKS ON A NON-

CONTACT BASIS

IMPROVED QUALITY ARISING FROM REAL-TIME DETECTION OF

INCORRECTLY PACKED CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS• SINGLE SENSOR

ACCOMMODATES A RANGE OF CARTON SIZES WITHOUT

REPOSITIONING

REMOTE ADJUSTMENT VIA IO-LINK REDUCES CHANGEOVER

TIME BETWEEN PRODUCTS

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 300MM WITH PINPOINT RED

LED

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

CUSTOMER SOLUTION

Rugged photoelectric sensors with background suppression

from the Contrinex C23 range are ideal for this application. A

pinpoint red LED with a 10mm-diameter light spot at the

maximum sensing range of 300mm ensures highly reliable

detection of objects of almost any colour against light or dark

backgrounds. These sensors are well suited to both the task

and the environment.

Immediately after packing, a single sensor is mounted

centrally above the conveyor. As each carton passes below on

its way to the sealing station, the sensor detects the top

surface of the packed bags. If the height of the top layer falls

outside preset limits, the sensor triggers a reject mechanism

that diverts the carton to a holding area for investigation.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

Locating sensors optimally is simple thanks to a custom-

designed range of multi-position mounting brackets. An

operating range between 15mm and 250mm accommodates a

variety of carton sizes without any need to reposition the

sensor. A simple electrical adjustment via an onboard

potentiometer suffices, while remote adjustment via IO-Link, a

standardized point-to-point serial connection protocol, is

available as standard at no extra cost for PNP versions

CUSTOMER VALUES

NON-CONTACT SENSING

MOUNTING OUT OF HARM’S WAY

RELATIVELY TAMPER PROOF

PRODUCT ADVANTAGES

CHOICE OF CUBIC C23PA OR CYLINDRICAL M18MA BODIES

SMALL SIZE - 20 x 30 x 10mm or Ø18 x 37mm

SENSING RANGE UP TO 300MM / 250MM RESPECTIVELY

EASY ADJUSTMENT DUE TO VISIBLE BEAM

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

Cotton spinning machines use a robotic vacuum cleaning

system to prevent lint build-up on machinery and product. To

ensure the vacuum cleaning robot does not collide with the

spinning machine, a Contrinex Background Suppression

photoelectric sensor detects their presence.

CUSTOMER APPLICATION

Lint is generated from the process of spinning cotton and if

lint is allowed to accumulate, it will eventually clog the small

eyelets and guides on the spinning machine.

Because a build-up of lint can cause yarn breakage, spinning

machinery is equipped with vacuum systems that constantly

rove the machine to collect lint. These systems depend on a

relatively slow-moving vacuum head, which travels on a rail

mounted above.

The spinning machines are tended by operators who might

accidentally leave items in the path of the vacuum head. To

prevent collisions with these objects, the existing detection

system on the vacuum head consists of a limit switch with a

mechanical wand attachment. As soon as the wand touched

an obstacle, it caused the vacuum head to reverse its direction

of travel, but the customer wanted to upgrade to a non-

contact detection solution more suited to an automated

environment.

CUSTOMER SOLUTION

Contrinex’s LHR-C23PA cubic and LHR-M18PA background

suppression photoelectric sensors are ideal for this application.

Despite their small size (20 x 30 x 10mm or Ø18 x 37mm), these

sensors are both robust and high-performance offering a

sensing range of 300 or 250mm respectively.

The sensor’s precise background suppression enables them to

detect the presence of any obstacle regardless of colour,

brightness or angle in relation to the position of the sensor on

the vacuum head.

The LHR-C23PA cubic sensor is mounted on the vacuum head

to provide sensing for the robotic system’s safety reversal

function. The operating range can be adjusted to detect an

obstacle between 15 to 250 mm away, in which case the

cleaning machine simply reverses its direction of travel,

without interrupting the cleaning function.

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

VIDEO, READ APPLICATION EXAMPLES BELOW,

CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP GUIDE

YOU THROUGH SELECTION, ANSWER QUESTIONS, OR

TO HELP YOU #MAKESENSEOFSENSORS:

STANDARD

PHOTOELECTRIC SENSORS

CONTRINEX’S PHOTOELECTRIC SENSORS EXCEL

AT POSITIONING AND PRESENCE-DETECTION -

FOR EXAMPLE HIGH-PERFORMANCE, INDUSTRY

LEADING SENSING DISTANCES AND

OUTSTANDING BACKGROUND SUPPRESSION

CHARACTERISTICS, COMBINE TO GIVE HIGH

ACCURACY AND RELIABILITY.

CUSTOMER VALUES

RELIABLE CHECK OF ASSEMBLY TO AVOID CUSTOMER

REJECTIONS

RECORDABLE CONFIRMATION OF GEAR MODEL

PRODUCT ADVANTAGES

RUGGED LASER SENSOR WITH METAL HOUSING

SENSING RANGE UP TO 250MM

BUILT-IN CHANGEOVER OUTPUTS

EASY ADJUSTMENT DUE TO VISIBLE BEAM

ADJUSTABLE FOCUS OF BEAM

A manufacturer of assembled, forged and machined

components for the automotive industry trusts Contrinex

distance sensing photoelectric sensors to ensure that the

correct gear model is selected in an assembly.

CUSTOMER APPLICATION

Because the manufacturer has two models of gears, both of

which are designed to fit into the same location in the

assembly, care must be taken over which version is being

produced.

During the production process for each specific assembly,

confirmation is required that the correct gear model has been

mounted. This is achieved by verifying the assembly as a

whole. Since the height of the assembled component differs

depending on which gear model has been mounted,

immediate identification of assembly height is the chosen

sensing solution. Space is limited, so a compact sensor with a

long sensing range is required.

CUSTOMER SOLUTION

Contrinex’s LTS-1180L-103 compact M18 photoelectric laser

sensors is ideal for this application. Its compact size, easy

adjustment and rugged metal housing make it suitable for

this tough industrial environment.

The mounted assembly has a curved section at the top. The

sensor’s task is to detect the highest point of this curved

section and verify the height of the finished component. The

small beam spot of this laser sensor is therefore essential. By

targeting the beam of sensor on this curved part, when the

correct gear is in place the beam will be deflected and the

sensor will not trigger the output. However, if the wrong part is

mounted, i.e. with more height, it will obstruct the sensor

beam and trigger the sensor output. By using a sensor with

integral changeover outputs, the same sensor can be used to

verify both models. Only one selection switch is required.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE POSITION SENSING ON A NON-

CONTACT BASIS

IMPROVED THROUGHPUT ARISING FROM REAL-TIME

DETECTION OF INCORRECTLY POSITIONED OR MISSING

CARTONS

INCREASED PRODUCTIVITY AS STABILITY ALARM FLAGS

PREVENTATIVE-MAINTENANCE NEEDS

SINGLE SENSOR ACCOMMODATES A RANGE OF CARTON SIZES

WITHOUT REPOSITIONING

PRODUCT ADVANTAGES

MAXIMUM SENSING RANGE OF 8000MM WITH 78MM-

DIAMETER REFLECTOR

BEST-IN-CLASS BACKGROUND-SUPPRESSION BLACK/WHITE

BEHAVIOUR

IO-LINK CONNECTIVITY IDEAL FOR INDUSTRY 4 & IIOT

PREVENTATIVE MAINTENANCE STABILITY ALARM OPTION

During confectionery packaging operations, conveyor lines

deliver preformed cardboard cartons to packing stations. At

each station, a pick-and-place packing robot packs layers of

bagged candy in cartons. Once filled, cartons are conveyed to

case-sealing stations. A highly reliable retro-reflex

photoelectric sensor, mounted beside the line, senses each

carton as it arrives at the packing station, halting the conveyor

and initiating the packing sequence once it is correctly

positioned.

CUSTOMER APPLICATION

In the confectionery-manufacturing industry, secondary

packaging is usually required when preparing multiple

product packs for wholesale distribution. In high-volume

production, manufacturers pack sealed bags of candy in

cardboard cartons, which are in turn stacked for shrink-

wrapping and palletisation.

Preformed cartons arrive at the packing station in a

continuous stream. Once the leading carton reaches its

designated position, the conveyor halts and the packing

sequence commences. A pick-and-place robot lifts successive

layers of bags and lowers them into the carton. Once the

predetermined number of bags has been packed, the carton is

conveyed to a sealing station.

If a carton stops in the wrong position, or if no carton is

present, the packing sequence must be inhibited to prevent

damage occurring. A non-contact sensor system is needed to

detect the position of the leading carton as it arrives at the

packing station, halting the conveyor and initiating the

packing sequence once. It must be reliable and require

minimal maintenance.

CUSTOMER SOLUTION

Miniature retro-reflex photoelectric sensors from the Contrinex

C23 range are ideal for this application. Used in conjunction

with a 41mm-diameter reflector, these sensors have an

operating range of up to 4500mm – more than adequate for

the task. A single sensor is mounted beside the carton

conveyor, immediately before the packing station, with the

reflector positioned on the opposite side. As the leading carton

breaks the light beam, the sensor detects its presence and

halts the conveyor in the correct position for packing.

Mounted in 20mm x 30mm x 10mm miniature plastic

housings, C23 photoelectric sensors are available with

industry-standard PNP or NPN 3-wire or 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry. A second output provides a

stability alarm in the event of reduced sensitivity, flagging the

need for preventative maintenance before any performance

degradation occurs.

A custom-designed range of multi-position mounting

brackets allows systems engineers to locate sensors optimally

in almost any situation. The C23 range detects slow- or fast-

moving targets reliably. Remote selection of switching

frequency is possible via IO-Link, a standardized point-to-point

serial connection protocol, available as standard at no extra

cost for PNP versions.

At busy container seaports, purpose-designed container-

handling vehicles called Straddle Carriers, operate around the

clock, loading, unloading and stacking containers. Space

utilisation is increasingly important and correctly identifying

the size of container picked for each lift is essential for

efficiency.

Contrinex photoelectric sensors have been fitted to the

Straddle Carriers to detect the container size and eliminate the

need for drivers to carry out identification checks, saving time

and avoiding errors.

CUSTOMER APPLICATION

A fleet of straddle carriers, purpose-designed container-

handling vehicles, services a busy French container port. As a

straddle carrier moves over a container, a central lifting beam

lowers and locks onto the corner castings of the container;

each lift comprises either a single 40-foot container or two 20-

foot containers.

Optimal utilisation of storage space is essential; correctly

identifying the size of container picked for each lift is vital.

Fitting carriers with sensors that detect the size and type of

containers at the time of lifting eliminate the need for drivers

to carry out identification checks, saving time and avoiding

errors.

The original mechanical sensors proved unreliable, losing

calibration when subjected to continuous vibration during

normal operation. Although the scheduled maintenance

interval for each vehicle is 1,000 hours, mechanical sensors

required recalibration at intervals of no more than two or three

days. A highly stable replacement sensor system was desired.

CUSTOMER SOLUTION

Highly stable, non-contact, all-electronic units from the

Contrinex range of photoelectric sensors provide a reliable and

cost-effective alternative. The moulded-resin sensor casings,

fitted with coated-plastic sensing faces, are IP67 rated, making

them virtually impervious to the harsh, salt-laden environment

of a busy container port. Connection to the vehicle’s control

systems is via an integral M12 connector and PVC-sheathed

cable, allowing easy removal and replacement during routine

maintenance.

To confirm the size of the container, two pairs of diffuse

sensors with background suppression are mounted centrally

on each lifting beam. As the lifting beam descends, one sensor

from each pair detects the presence or absence of corner

castings at the central lifting points, while the other detects

the presence or absence of the gap between two 20-foot

containers. The combination of the two eliminates incorrect

identification in the unlikely event that the first sensor returns

a false-positive signal from a 40-foot container.

A physically small housing and long sensing distances

eliminate the risk of accidental damage arising from a

mechanical collision, while rugged industry-standard housings

and vacuum-encapsulated electronics minimise the effects of

vibration.

Operational results have been excellent; the new Contrinex

sensors have eliminated calibration errors and reduced

maintenance costs significantly.

STANDARD PHOTOELECTRIC SENSORS -

EXCELLENCE IN PRICE & PERFORMANCE.

CUSTOMER VALUES

NON-CONTACT, ALL-ELECTRONIC DEVICE WITH SENSING

RANGE UP TO 500MM.

LARGE SENSING RANGE AVAILABLE IN A PHYSICALLY SMALL

SENSOR.• EXCEPTIONAL RESISTANCE TO EXTREME VIBRATION

DURING OPERATION.

OPTIMAL SPACE UTILISATION WITH LITTLE OR NO RELIANCE

ON OPERATOR INVOLVEMENT

PRODUCT ADVANTAGES

ELIMINATION OF CALIBRATION ERRORS DURING NORMAL

OPERATION

LARGE SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

PROVIDES RELIABLE, REPEATABLE SENSING IN DEMANDING

OPERATING CONDITIONS

Contrinex’s C23 photoelectric sensor family is small but

powerful and so ideal for conveyor and packaging applications.

An example application for the C23 is the food processing

industry, where ‘shingling’, or overlapped layering, is a

common technique for optimizing space during secondary

packaging operations. As shown in the video, biscuits are

sealed in gusseted bags with a triangular profile, and packed

in alternating, overlapping layers into a preformed cardboard

box. Once each box is full, it passes to a case-sealing station

prior to palletisation and dispatch.

From time to time, an incorrectly formed layer occurs, where a

bag might be damaged or misaligned. The C23 photoelectric

sensor with Background Suppression is used to provide non-

contact sensing of the height of the top layer of bags, rejecting

any over-filled cartons.

CUSTOMER APPLICATION

In the food processing industry, shingling, or overlapped

layering, is a common technique for optimising space

utilisation during secondary packaging operations.

Confectionery, sealed in gusseted bags with predominantly

triangular profiles, is packed in alternating, overlapping layers

in preformed cardboard cartons. Once each carton is full, it

passes to a case-sealing station prior to palletisation and

dispatch.

Pre-aligned bags of confectionery arrive at the packing station

in regularly spaced rows. At each station, a multi-axis pick-and-

place packing robot lifts a row of bags, aligns it and lowers it

into a preformed carton. Successive layers overlap each other,

ensuring that space within the carton is fully utilised. Once the

predetermined number of layers has been packed, the carton

is conveyed to the sealing station.

From time to time, one or more incorrectly formed layers

occur. Individual bags may be missing from a row on arrival at

the packing station, or may be damaged or misaligned. A non-

contact sensor is needed to sense the height of the top layer of

bags, rejecting any defective cartons. It must be reliable and

require minimal maintenance.

Contrinex Standard photoelectric sensors are ideal for general

position and presence-detection for almost any industry and

application. Best-in-class performance such as sensing ranges

and background suppression characteristics, the Standard

range of sensors delivers very high accuracy and reliability.

A wide variety of housing designs and sizes are offered::

•

Cubic sizes: 0507 (5 x 7 x 40mm), C12 (13 x 21 x 7mm), C23

(20 x 30 x 10mm), 3030 (30 x 30 x 15mm), 4040 (40 x 40 x

19mm), 4050 (40 x 50 x 15mm) and C55 (50 x 50 x 23mm).

•

Cylindrical types are also available in sizes M12 and M18.

C23 20 X 30 X 10MM

Standard C23 and M18P series are high quality ASIC sensors

with an integral IO-Link interface in PNP types. This makes

them particularly suitable for smart factory applications. IO-Link

extends sensor functionality to include continuous monitoring

of process data, continuous diagnosis of sensor status,

advanced parameter settings, sensitivity adjustment, a remote

teach function and easy checking of sensor ID, to ensure the

right sensor is at the right place.

TECHNOLOGY

Diffuse

A diffuse-mode, or energetic-diffuse, photoelectric sensor is a

reflective sensor, containing a transmitter and a receiver in a

single housing. The sensor emits a focused light beam toward a

distant target that acts as a reflector, returning part of the

transmitted light to the sensor. The receiver detects the amount

of light reflected by the target, triggering the sensor when the

light intensity reaches a threshold value.

•

Ideal for short sensing ranges and relatively easy targets

•

Easy installation and alignment

•

No separate reflector or receiver

Background-Suppression

Diffuse-mode photoelectric sensors with background

suppression emit a focused light beam toward a distant target.

Part of the beam is reflected from the target and returns to the

sensor, striking a position-sensitive receiver. The receiver

distinguishes between reflections from the target and

reflections from background objects, only triggering the sensor

when the signal reaches a value that corresponds to the preset

target distance.

•

Target size, colour, shape and surface finish have little

influence on sensing range

•

Suitable for difficult targets (small, fast-moving, light

background)

•

No separate reflector or receiver”

Reflex

A reflex, or reflective, photoelectric sensor contains a transmitter

and a receiver in a single housing, and emits a pulsed, focused

light beam through a polarisation filter toward a distant

reflector. Reflected light returns to the sensor, passing through

a second filter before arriving at the receiver. When a target

object interrupts the light beam, the receiver detects the

reduced light intensity and triggers the sensor. Auto-collimation

of the light beam allows blind-zone suppression.

•

Ideal for moderate sensing ranges

•

Wiring required for just one emitter/receiver unit

•

Separately mounted reflector

Through-beam

Contrinex through-beam photoelectric sensors are ideal for

industrial applications where sensing components must be

mounted some distance from the target area. Through-beam

sensors utilise infra-red, visible and laser light sources to detect

targets, reliably and repeatably, at extended distances.

•

Ideal for long sensing ranges

•

Suitable for contaminated environments or highly

reflective targets

•

Separately mounted and wired receiver

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER VALUES

ECONOMICAL, FAST AND ABSOLUTELY RELIABLE

NON-CONTACT OPERATION, TO AVOID MECHANICAL WEAR

EXCELLENT PERFORMANCE COMBINED WITH SMALL SIZE

LONG SERVICE LIFE

SENSORS READY MADE-UP AND EASY TO USE

FLEXIBILITY OF SOLUTION

PRODUCT ADVANTAGES

LARGE OPERATING DISTANCE AND SIGNAL RESOLUTION

PROTECTION CLASS IP 67

OUTSTANDING PERFORMANCE ON DETECTION

ACCURACY, SPEED AND FREQUENCY

A manufacturer of automated laboratory equipment for in-

vitro diagnostics trusts the long operating distance and high

resolution of Contrinex’s reflex photoelectric sensors to detect

the if a cap is fitted on a blood testing vial which is a small

glass test-tube.

CUSTOMER APPLICATION

To automate the placement of the small test-tubes into carrier

racks, a machine picks test-tubes from a conveyor. It is

essential that the vials are pushed into the carrier racks the

right way up, with the cap uppermost. The challenge is that

whilst the test tubes are aligned parallel to each other on the

feed conveyor, they can be positioned with the orientation of

the tube having the cap to the right, or to the left.

The shape and material of the test-tubes makes measuring

them difficult because they are round, transparent and filled

with liquid in varying quantities, with indistinct contours and a

lack of planar surfaces. Camera-based identification systems

or profile scanners were considered to be too expensive.

Additionally , the customer needed a quick solution that was

reliable as well as economic.

CUSTOMER SOLUTION

Test-tubes lying on the conveyor pass under a lightweight

lever which traces the contour of the test-tube, rising or falling

accordingly. The side of the lever facing the photoelectric

sensor provides a planer surface, guaranteeing absolutely

reliable measurement.

The sensor can detect the fitted cap because it has a 2mm

larger diameter than the test tube. Therefore, the machine’s

controller polls the sensor every 20 ms, and uses its analogue

value to determine the position of the larger cap

mathematically. According to this measurement, the machine

then turns the test-tube the right way up and pushes it into

the rack. A test-tube without a cap is identified by the sensor

as an error, since no significant difference can be detected and

the machine stops running. The automation enables one test-

tube to be inserted every second and ensures their correct

orientation.