(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

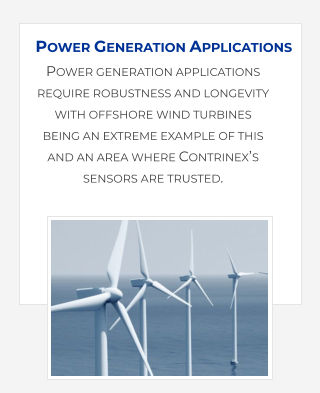

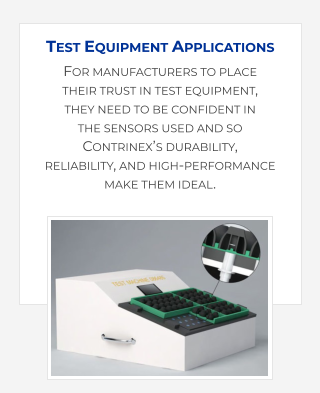

EXAMPLE APPLICATIONS

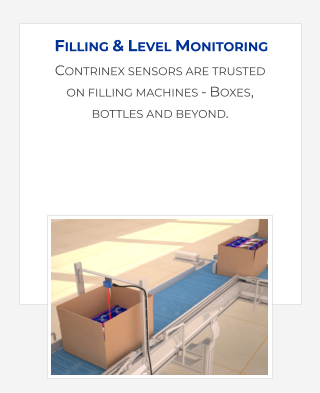

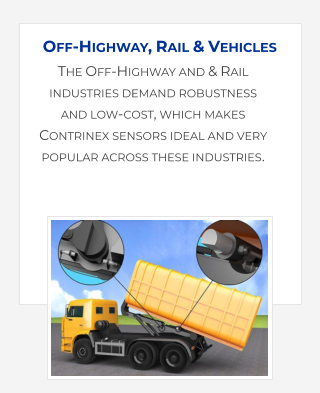

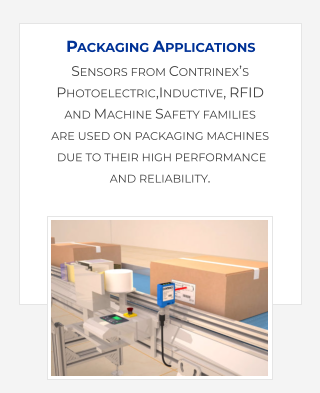

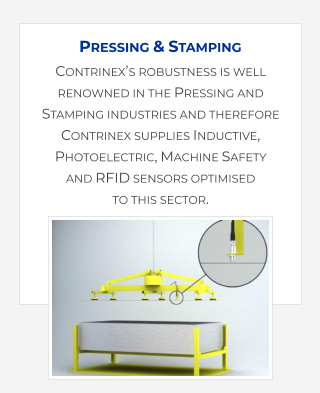

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

RELIABLE, CONTINUOUS TOOL OPERATION IN TIME-SENSITIVE

PRODUCTION ENVIRONMENTS

SIGNIFICANT ENHANCEMENT OF TOOL FUNCTION WITH

MINIMAL EFFECT ON SIZE OR WEIGHT

LOW RISK OF INTERNAL DAMAGE DUE TO BEST-IN-CLASS

SENSING DISTANCES

INDUSTRY-STANDARD INTERFACE REQUIRES LITTLE

MODIFICATION TO CONTROL SYSTEMS

PRODUCT ADVANTAGES

SENSOR PERFORMANCE UNAFFECTED BY 500 BAR (7255 PSI)

OPERATING PRESSURE

CONDIST® TECHNOLOGY OF EXTRA DISTANCE FAMILY

DELIVERS BEST-IN-CLASS SENSING DISTANCES

SMALL, LIGHTWEIGHT EMBEDDABLE SENSORS WITH HIGH-

PRESSURE CAPABILITY

RUGGED INDUCTIVE SENSOR WITH METAL HOUSING AND

CERAMIC SENSING FACE

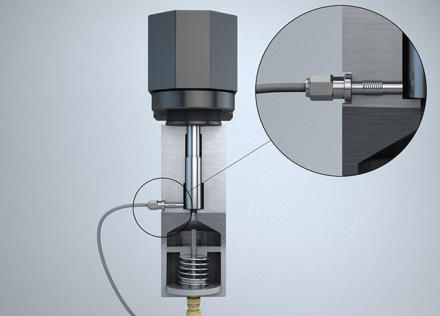

A manufacturer of cold-forming tools for joining sheet metal

uses position sensing to control the operation of a manual

punch-riveting tool. A high-pressure inductive sensor

mounted directly into the wall of a small pneumohydraulic

cylinder detects the position of the hydraulic ram, preventing

the operating cycle from starting unless the ram is fully

retracted.

CUSTOMER APPLICATION

Automotive technicians assembling prototype vehicle bodies

during pre-production use manual punch-riveting tools to join

individual sheet-metal parts. Several thousand joints are

required per vehicle, and tools must be compact since space is

often limited.

Bad joints, which are very costly to repair, can occur if the

technician does not set the tool correctly before triggering it.

During use, the tool-head is often partly hidden from view, so a

sensing system must confirm that the operating ram is fully

retracted and prevent the tool from operating if the ram is not

in the correct position.

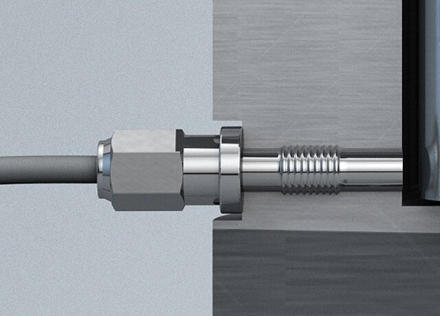

A pneumohydraulic cylinder drives the ram, and the compact

nature of the tool limits the allowable sensor size. The sensing

face is exposed to the high-pressure side of the hydraulic

circuit, so the sensor must withstand continuous pressures up

to 500 bar (7255 psi) and pressure spikes of 1000 bar (14,510

psi).

CUSTOMER SOLUTION

Robust inductive sensors from the Contrinex Extra Distance

family, High Pressure range, withstand the high operating

pressure of this application. The extended operating distance

of patented Condist® technology allows the use of thick,

hermetically sealed ceramic discs on the sensing faces without

compromising the sensors’ performance.

These lightweight M5- and M8-diameter embeddable sensors

are 27 mm and 30 mm in length, respectively. The sensors are

mounted directly into the wall of the cylinder and do not

interfere with the normal operation of the tool. Sensing

distances of 1mm (M5 sensor) and 1.5 mm (M8 sensor)

eliminate any risk of internal mechanical damage through

contact with the ram.

The sensors have an industry-standard PNP normally-open

configuration and connect with the customer’s control system

via a flexible PUR-sheathed cable. Vacuum-encapsulated

electronics ensure excellent resistance to shock and vibration,

and no additional electrical or mechanical protection is

required.

Previously, users of the punch-riveting tools were unable to

check the position of the operating ram with the tool in situ

and either incurred downtime or risked costly bad joints.

Contrinex high-pressure inductive sensors satisfy the

manufacturer’s requirement for small, lightweight, ultra-

reliable sensors with an attractive total cost of ownership.

CONTRINEX HELP KEEP YOU CALM UNDER PRESSURE WITH THEIR RANGES OF ‘EXTRA’ & HIGH’

PRESSURE SENSORS WHICH ARE TRUSTED IN A WORLD OF CHALLENGING APPLICATIONS.

INDUCTIVE SENSORS DESIGNED FOR ‘Extra’ PRESSURE (200 BAR) AND

‘High’ PRESSURE (500 BAR / 1000 BAR PEAK)- ‘COOL UNDER PRESSURE’

PRODUCT ADVANTAGES

EXTRA - PRESSURE RESISTANT UP TO 200 BAR

HIGH - HIGHEST OPERATING AND PEAK PRESSURES (500

BAR, 1000 BAR PEAK)

EXTRAORDINARY LIFE TIME UNDER PRESSURE CYCLE

EXCEPTIONAL RELIABILITY IN MINIATURE PACKAGES

EXTRA - SUITABLE FOR HIGH VACUUM APPLICATIONS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Dependable, accurate presence- and position-sensing at pressures up to 200 bar for the ‘EXTRA’ range or 500 bar (1,000 bar peak)

for the ‘HIGH PRESSURE’ range of sensors.

The EXTRA PRESSURE inductive sensors deliver can operate continuously in permanently pressurised conditions and at water

depths up to 1,000 metres. Their combination of a stainless-steel housing and a permanently bonded ceramic or sapphire-glass

sensing face guarantees robustness and exceptional reliability in miniature packages sized from ø3 to M8.

Contrinex HIGH PRESSURE inductive sensors are suitable for continuous duty at pressures up to 500 bar (1,000 bar peak pressure),

ensuring reliable, accurate sensing in the most demanding pneumatic and hydraulic applications. Available with classic metal

housing or one-piece, stainless-steel construction, high-pressure sensors detect the smallest parts and are ideal for piston-control

applications where space is at a premium.

EXTRA & HIGH PRESSURE INDUCTIVE SENSORS

CUSTOMER VALUES

RELIABLE OPERATION DESPITE HIGH-OPERATING PRESSURES

EASE OF MOUNTING

REDUCED MAINTENANCE COSTS

INCREASED EFFICIENCY

PRODUCT ADVANTAGES

PRACTICALLY UNLIMITED NUMBER OF PRESSURE CYCLES

ACROSS THE PRESSURE RANGE – 10 TIMES GREATER

LONGEVITY THAN THE MARKET STANDARD

PEAK PRESSURE UP TO 1000 BAR (14500 PSI)

LONG OPERATING DISTANCES DESPITE PRESSURE RESISTANT

HOUSING

RESISTANCE TO DYNAMIC STRESSES

Manufacturers of mobile concrete pumping trucks trust

Contrinex’s High Pressure sensors to monitor the piston

position in the hydraulic drive cylinder.

These sensors provide exceptional reliability despite the

challenges of pressure cycles and high pressure peaks,

increasing longevity and efficiency and reducing maintenance

costs for these concrete pump.

An additional benefit is that these sensors are part of

Contrinex’s Extra Distance family and so combine long

operating distances despite the pressure resistant housing.

CUSTOMER APPLICATION

Concrete pumps use a double-piston pump and require two

feed cylinders that pump concrete at a working pressure of up

to 400 bar (5800 psi). These feed cylinders are driven by pairs

of hydraulic cylinder pairs which operate in push-pull

opposition. To achieve the maximum possible efficiency, the

timing of this push-pull operation must be precisely

coordinated. It is therefore essential to monitor the cylinder

limit position with sensors that are resistant to high-pressure.

The dynamic stresses on all components built into the

hydraulic system are very high, due to constantly changing

pressure cycles during pump operation.

Concrete pump failures are extremely costly because they can

cause construction problems and stoppages and risk

compromising the building being constructed.

If the breakdown is due to problems in the hydraulic system,

all the hydraulic oil must be drained to correct the fault. Then,

after refilling and before start-up, several time-consuming de-

aeration cycles must take place before the pump is fully fit for

service again. This prolongs the construction stoppage.

The customer’s requirements for longevity and resistance to

high peak pressures are essential to guarantee the smooth

operation of such systems.

CUSTOMER SOLUTION

Contrinex High Pressure sensors (series 500P) withstand the

necessary pressure levels (peak pressure up to 1000 bar - 14500

psi) due to a patented process whereby a solid ceramic disk is

built into the stainless steel housing.

These sensors are fully resistant to dynamic stresses. A

patented technology ensures that all electronics, including the

ferrite core and coil, are located on the unpressurised side of

the housing. This results in an unusually long life under

pressure cycle stresses.

To monitor cylinder limit positions in the concrete pump, two

sensors are installed and connected to the control system. Due

to their longevity, which is ten times greater than the market

standard, maintenance costs are reduced to a minimum.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

EXTRA & HIGH PRESSURE

INDUCTIVE SENSORS

CONTRINEX HELP KEEP YOU CALM UNDER PRESSURE

WITH THEIR RANGES OF ‘EXTRA’ & HIGH’ PRESSURE

SENSORS WHICH ARE TRUSTED IN A WORLD OF

CHALLENGING APPLICATIONS.

CUSTOMER VALUES

FAST AND EASY UPGRADE OF MECHANICAL LIMIT SWITCHES

TOOL-FREE MOUNTING

ROTATABLE SENSING FACE, MOUNTABLE IN FIVE DIRECTIONS

SIGNIFICANT REDUCTION IN DOWNTIME

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE UP TO 40 MM

HIGHLY FLEXIBLE, RELIABLE AND ECONOMICAL

SUITABLE FOR HARSH ENVIRONMENTS AND TEMPERATURES

FROM -25°C TO +85°C

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

HIGH SWITCHING FREQUENCIES, RELIABLE SWITCHING

CHANGEOVER OUTPUTS

4 LED INDICATORS• IO-LINK INTERFACE

A manufacturer of cold-forming tools for joining sheet metal

uses position sensing to control the operation of a manual

punch-riveting tool. A high-pressure inductive sensor

mounted directly into the wall of a small pneumohydraulic

cylinder detects the position of the hydraulic ram, preventing

the operating cycle from starting unless the ram is fully

retracted.

CUSTOMER APPLICATION

Automotive technicians assembling prototype vehicle bodies

during pre-production use manual punch-riveting tools to join

individual sheet-metal parts. Several thousand joints are

required per vehicle, and tools must be compact since space is

often limited.

Bad joints, which are very costly to repair, can occur if the

technician does not set the tool correctly before triggering it.

During use, the tool-head is often partly hidden from view, so a

sensing system must confirm that the operating ram is fully

retracted and prevent the tool from operating if the ram is not

in the correct position.

A pneumohydraulic cylinder drives the ram, and the compact

nature of the tool limits the allowable sensor size. The sensing

face is exposed to the high-pressure side of the hydraulic

circuit, so the sensor must withstand continuous pressures up

to 500 bar (7255 psi) and pressure spikes of 1000 bar (14,510psi).

CUSTOMER SOLUTION

Robust inductive sensors from the Contrinex Extra Distance

family, High Pressure range, withstand the high operating

pressure of this application. The extended operating distance

of patented Condist® technology allows the use of thick,

hermetically sealed ceramic discs on the sensing faces without

compromising the sensors’ performance.

These lightweight M5- and M8-diameter embeddable sensors

are 27 mm and 30 mm in length, respectively. The sensors are

mounted directly into the wall of the cylinder and do not

interfere with the normal operation of the tool. Sensing

distances of 1mm (M5 sensor) and 1.5 mm (M8 sensor)

eliminate any risk of internal mechanical damage through

contact with the ram.

The sensors have an industry-standard PNP normally-open

configuration and connect with the customer’s control system

via a flexible PUR-sheathed cable. Vacuum-encapsulated

electronics ensure excellent resistance to shock and vibration,

and no additional electrical or mechanical protection is

required.

Previously, users of the punch-riveting tools were unable to

check the position of the operating ram with the tool in situ

and either incurred downtime or risked costly bad joints.

Contrinex high-pressure inductive sensors satisfy the

manufacturer’s requirement for small, lightweight, ultra-

reliable sensors with an attractive total cost of ownership.

INDUCTIVE SENSORS DESIGNED FOR

‘Extra’ PRESSURE (200 BAR) AND

‘High’ PRESSURE (500 BAR / 1000 BAR PEAK)

- ‘COOL UNDER PRESSURE’

PRODUCT ADVANTAGES

EXTRA - PRESSURE RESISTANT UP TO 200 BAR

HIGH - HIGHEST OPERATING AND PEAK PRESSURES (500

BAR, 1000 BAR PEAK)

EXTRAORDINARY LIFE TIME UNDER PRESSURE CYCLE

EXCEPTIONAL RELIABILITY IN MINIATURE PACKAGES

EXTRA - SUITABLE FOR HIGH VACUUM APPLICATIONS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Dependable, accurate presence- and position-sensing at

pressures up to 200 bar for the ‘EXTRA’ range or 500 bar (1,000

bar peak) for the ‘HIGH PRESSURE’ range of sensors.

The EXTRA PRESSURE inductive sensors deliver can operate

continuously in permanently pressurised conditions and at

water depths up to 1,000 metres. Their combination of a

stainless-steel housing and a permanently bonded ceramic or

sapphire-glass sensing face guarantees robustness and

exceptional reliability in miniature packages sized from ø3 to

M8.

Contrinex HIGH PRESSURE inductive sensors are suitable for

continuous duty at pressures up to 500 bar (1,000 bar peak

pressure), ensuring reliable, accurate sensing in the most

demanding pneumatic and hydraulic applications. Available

with classic metal housing or one-piece, stainless-steel

construction, high-pressure sensors detect the smallest parts

and are ideal for piston-control applications where space is at a

premium.

CUSTOMER VALUES

RELIABLE OPERATION DESPITE HIGH-OPERATING PRESSURES

EASE OF MOUNTING

REDUCED MAINTENANCE COSTS

INCREASED EFFICIENCY

PRODUCT ADVANTAGES

PRACTICALLY UNLIMITED NUMBER OF PRESSURE CYCLES

ACROSS THE PRESSURE RANGE – 10 TIMES GREATER

LONGEVITY THAN THE MARKET STANDARD

PEAK PRESSURE UP TO 1000 BAR (14500 PSI)

LONG OPERATING DISTANCES DESPITE PRESSURE RESISTANT

HOUSING

RESISTANCE TO DYNAMIC STRESSES

Manufacturers of mobile concrete pumping trucks trust

Contrinex’s High-Pressure sensors to monitor the piston

position in the hydraulic drive cylinder.

These sensors provide exceptional reliability despite the

challenges of pressure cycles and high-pressure peaks,

increasing longevity and efficiency and reducing maintenance

costs for these concrete pump.

An additional benefit is that these sensors are part of

Contrinex’s Extra Distance family and so combine long

operating distances despite the pressure resistant housing.

CUSTOMER APPLICATION

Concrete pumps use a double-piston pump and require two

feed cylinders that pump concrete at a working pressure of up

to 400 bar (5800 psi). These feed cylinders are driven by pairs

of hydraulic cylinder pairs which operate in push-pull

opposition. To achieve the maximum possible efficiency, the

timing of this push-pull operation must be precisely

coordinated. It is therefore essential to monitor the cylinder

limit position with sensors that are resistant to high-pressure.

The dynamic stresses on all components built into the

hydraulic system are very high, due to constantly changing

pressure cycles during pump operation.

Concrete pump failures are extremely costly because they can

cause construction problems and stoppages and risk

compromising the building being constructed.

If the breakdown is due to problems in the hydraulic system,

all the hydraulic oil must be drained to correct the fault. Then,

after refilling and before start-up, several time-consuming de-

aeration cycles must take place before the pump is fully fit for

service again. This prolongs the construction stoppage.

The customer’s requirements for longevity and resistance to

high peak pressures are essential to guarantee the smooth

operation of such systems.

CUSTOMER SOLUTION

Contrinex High-Pressure sensors (series 500P) withstand the

necessary pressure levels (peak pressure up to 1000 bar - 14500

psi) due to a patented process whereby a solid ceramic disk is

built into the stainless steel housing.

These sensors are fully resistant to dynamic stresses. A

patented technology ensures that all electronics, including the

ferrite core and coil, are located on the unpressurised side of

the housing. This results in an unusually long life under

pressure cycle stresses.

To monitor cylinder limit positions in the concrete pump, two

sensors are installed and connected to the control system. Due

to their longevity, which is ten times greater than the market

standard, maintenance costs are reduced to a minimum.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS