(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

I

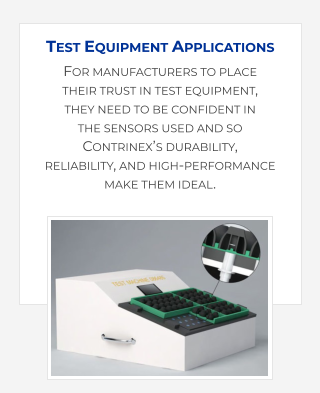

EXAMPLE APPLICATIONS

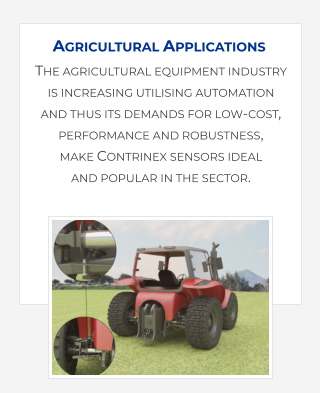

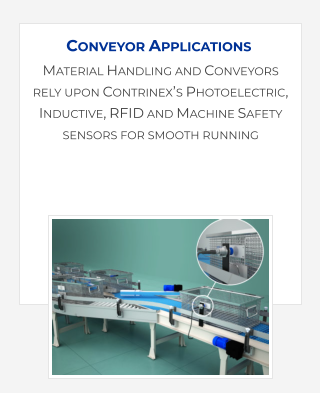

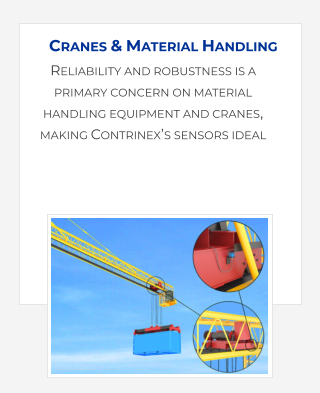

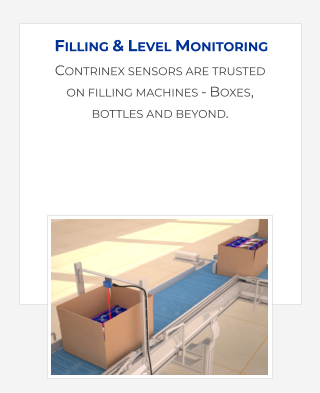

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

INDUSTRY LEADING CONTRAST & COLOUR SENSORS - EXCELLENCE IN DETECTING THE DIFFERENCE

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE DETECTION ON A NON-

CONTACT BASIS

REAL-TIME REJECTION OF UNIDENTIFIED OR UNTRACEABLE

PRODUCTS

REMOTE SET-UP VIA IO-LINK REDUCES NEED FOR MANUAL

INTERVENTION

PRODUCT ADVANTAGES

OPERATING RANGE UP TO 12MM WITH THREE-COLOUR RGB

EMISSION TECHNOLOGY

AUTOMATIC SELECTION OF BEST EMISSION COLOUR

IO-LINK CONNECTIVITY AVAILABLE AT NO EXTRA COST

HIGH SWITCHING FREQUENCY UP TO 10KHZ

VERSATILE INDUSTRY-STANDARD PUSH-PULL 4-WIRE OUTPUT

HIGH TOLERANCE TO OBJECT POSITION VARIATION AROUND

12MM

During high-volume production of confectionery, sealed

cartons of bagged candy travel by conveyor to a labelling

station. Contrinex’s versatile and high-performance, RGB light-

based photoelectric contrast sensor checks the label’s

alignment and confirms the presence of print registration

markings. If a label is blank, illegible or wrongly positioned, the

carton is diverted to a holding area for investigation.

CUSTOMER APPLICATION

In the food-processing industry, packaged consumer products

require labelling – both for identification and for batch control

– before final packing. During confectionery production, sealed

cartons of bagged candy travel by conveyor from carton-

taping stations to a label printer-applicator, before passing to

the final packing area.

The printer-applicator, which is located at one side of the

conveyor, produces a continuous feed of printed labels from

roll-stock. As each carton passes the applicator head, the label-

stock advances, peeling a single label and applying it to the

side of the carton.

From time to time, misfeeds or malfunctions occur within the

printer-applicator, which consequently applies labels that are

either blank, illegible or wrongly positioned. Failure to detect

these errors results in unidentified or untraceable products

arriving at subsequent operations or, critically, at the

customer’s premises.

A highly reliable non-contact sensor system is needed. The

sensor must detect the alignment of labels and confirm the

presence of print markings as cartons leave the printer-

applicator, rejecting any defective cartons.

CUSTOMER SOLUTION

A photoelectric contrast sensor from the Contrinex Cubic

Small range is ideal for this application. This versatile device

incorporates a single-lens autocollimator, delivering a narrow

optical beam that allows detection of very small features. The

choice of red, green or blue LED light, auto-selectable during

set-up, ensures optimal contrast resolution.

Immediately after the applicator, a single sensor is mounted

beside the conveyor; adjustable mounting brackets makes for

easy positioning. As the label on each carton passes the

detection point, changes in contrast trigger the sensor. The

transition from carton surface to label body identifies the

position and alignment of the label itself, while the well-

defined contrast between printed content and the label body

ensures reliable detection of even the smallest print marks.

If the label is wrongly aligned or the print markings missing,

the sensor triggers a reject mechanism that diverts the carton

to a holding area for investigation. An operating range up to

12mm allows adequate clearance between sensor and target,

while the compact 40mm x 50mm x 15mm PBTB plastic

housing is both mechanically robust and small enough to

accommodate any space constraints.

Set-up is accomplished either using a three-button keypad on

the sensor, or via IO-Link, a standardized point-to-point serial

connection protocol. Photoelectric contrast sensors are

available with industry-standard push-pull 4-wire output.

Connection to the customer’s control system is via a PVC-

sheathed cable with the choice of an integral M12 connector or

a hermetically sealed entry.

CONTRINEX’S COLOUR AND CONTRAST SENSORS OFFER INDUSTRY-LEADING PERFORMANCE

WHICH IS TRUSTED ACROSS THE PRINT LABELLING AND PACKAGING INDUSTRIES.

COLOUR & CONTRAST SENSORS

Contrinex’s Colour photoelectric sensors use energetic-diffuse sensing to detect variations in target color, to enable colour sorting

or colour control. Contrinex colour sensors feature five selectable tolerance levels for each of three separate outputs, which each

can be set using a “teach-in” function to recognise or ignore even the smallest variations of colour.

The Colour and Contrast sensors use the same rugged PBTP housing (40 mm x 50 mm x 15 mm) with IP67 enclosure rating and are

available in cable or adjustable (0°, 45° or 90°) connector versions.

Contrinex’s Contrast sensors offer exceptional performance for detecting print marks in printing, labelling and packaging

applications. Using a narrowly focused light beam and RGB (Red-Green-Blue light) emission technology, the contrast sensor

automatically selects the best emission colour during the teach-in procedure.

PRODUCT ADVANTAGES

DETECTION OF VERY SMALL PRINT MARKS THANKS TO A

NARROW, COLLIMATED LIGHT SPOT

OPTIMUM CONTRAST ENHANCEMENT THROUGH AUTOMATIC

SELECTION OF EMITTER DIODES IN DIFFERENT COLOURS

DETECTION OF THE SMALLEST DIFFERENCES IN CONTRAST

DUE TO HIGH CONTRAST RESOLUTION

TOLERANCE SELECTION AND EASY TEACH-IN OVER IO-LINK

HIGH SWITCHING FREQUENCY UP TO 10KHZ

VERSATILE INDUSTRY-STANDARD PUSH-PULL 4-WIRE OUTPUT

HIGH TOLERANCE TO OBJECT POSITION VARIATION AROUND

12MM

PRODUCT ADVANTAGES - PACKAGING MACHINES

FOR THE PRECISE RECOGNITION OF PRINT MARKS ON PACKAGING

FILM, WITHOUT SACRIFICING PROCESSING SPEED, A HIGHLY

ACCURATE, FAST AND RELIABLE SENSOR IS REQUIRED.

THE NEW CONTRAST SENSOR FROM CONTRINEX OFFERS ALL THIS

IN A VARIETY OF CONFIGURATIONS.

OPTIMIZED DETECTION OF PRINT MARKS

EASY TEACH-IN AND INSTALLATION

FULL REMOTE CONTROL WITH IO-LINK

PRODUCT ADVANTAGES- PRINTING & LABELLING MACHINES

IN PRINTING MACHINES, PRECISE POSITION SENSING IS REQUIRED,

EVEN WITH DIFFERENT PRINT COLOURS.

THE NEW CONTRINEX CONTRAST SENSOR ALLOWS ACCURATE

DETECTION THANKS TO TOLERANCE ADJUSTMENT. THIS ENSURES

THAT THE SENSOR ONLY RESPONDS TO PRINT MARKS AND

IGNORES OTHER COLOURED OBJECTS.

HIGH PRECISION DETECTION

ADJUSTABLE DETECTION TOLERANCE

SHORT CHANGEOVER TIMES DUE TO IO-LINK

Excellent contrast resolution, a high switching frequency (up

to 10 kHz) and five tolerance levels ensure accurate detection

and positioning, even when contrast differences are minimal.

The integral IO-Link interface can be used to reduce

changeover times through remote teach-in and

parameterisation. Other control functions, including

monitoring, diagnosis and switching timer adjustment are also

available using IO-Link.

.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

VIDEO, READ AN APPLICATION EXAMPLE BELOW,

CLICK HERE TO VIEW THIS SENSOR ON CONTRINEX’S

WEBSITE, OR CALL US TO HELP GUIDE YOU THROUGH

SELECTION, ANSWER QUESTIONS, OR TO HELP YOU

#MAKESENSEOFSENSORS:

PRODUCT ADVANTAGES

DETECTION OF VERY SMALL PRINT MARKS THANKS TO A

NARROW, COLLIMATED LIGHT SPOT

OPTIMUM CONTRAST ENHANCEMENT THROUGH AUTOMATIC

SELECTION OF EMITTER DIODES IN DIFFERENT COLOURS

DETECTION OF THE SMALLEST DIFFERENCES IN CONTRAST

DUE TO HIGH CONTRAST RESOLUTION

TOLERANCE SELECTION AND EASY TEACH-IN OVER IO-LINK

HIGH SWITCHING FREQUENCY UP TO 10KHZ

VERSATILE INDUSTRY-STANDARD PUSH-PULL 4-WIRE OUTPUT

HIGH TOLERANCE TO OBJECT POSITION VARIATION AROUND

12MM

PRODUCT ADVANTAGES- PRINTING & LABELLING MACHINES

IN PRINTING MACHINES, PRECISE POSITION SENSING IS REQUIRED,

EVEN WITH DIFFERENT PRINT COLOURS.

THE NEW CONTRINEX CONTRAST SENSOR ALLOWS ACCURATE

DETECTION THANKS TO TOLERANCE ADJUSTMENT. THIS ENSURES

THAT THE SENSOR ONLY RESPONDS TO PRINT MARKS AND

IGNORES OTHER COLOURED OBJECTS.

HIGH PRECISION DETECTION

ADJUSTABLE DETECTION TOLERANCE

SHORT CHANGEOVER TIMES DUE TO IO-LINK

PRODUCT ADVANTAGES - PACKAGING MACHINES

FOR THE PRECISE RECOGNITION OF PRINT MARKS ON PACKAGING

FILM, WITHOUT SACRIFICING PROCESSING SPEED, A HIGHLY

ACCURATE, FAST AND RELIABLE SENSOR IS REQUIRED.

THE NEW CONTRAST SENSOR FROM CONTRINEX OFFERS ALL THIS

IN A VARIETY OF CONFIGURATIONS.

OPTIMIZED DETECTION OF PRINT MARKS

EASY TEACH-IN AND INSTALLATION

FULL REMOTE CONTROL WITH IO-LINK

COLOUR & CONTRAST

SENSORS

CONTRINEX’S COLOUR AND CONTRAST SENSORS

OFFER INDUSTRY-LEADING PERFORMANCE WHICH IS

TRUSTED ACROSS THE PRINT LABELLING AND

PACKAGING INDUSTRIES.

CUSTOMER VALUES

FAST AND EASY UPGRADE OF MECHANICAL LIMIT SWITCHES

TOOL-FREE MOUNTING

ROTATABLE SENSING FACE, MOUNTABLE IN FIVE DIRECTIONS

SIGNIFICANT REDUCTION IN DOWNTIME

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE UP TO 40 MM

HIGHLY FLEXIBLE, RELIABLE AND ECONOMICAL

SUITABLE FOR HARSH ENVIRONMENTS AND TEMPERATURES

FROM -25°C TO +85°C

LONG LIFE, ESPECIALLY IN APPLICATIONS WITH TEMPERATURE

FLUCTUATIONS AND VIBRATIONS

HIGH SWITCHING FREQUENCIES, RELIABLE SWITCHING

CHANGEOVER OUTPUTS

4 LED INDICATORS• IO-LINK INTERFACE

During high-volume production of confectionery, sealed

cartons of bagged candy travel by conveyor to a labelling

station. Contrinex’s versatile and high-performance, RGB light-

based photoelectric contrast sensor checks the label’s

alignment and confirms the presence of print registration

markings. If a label is blank, illegible or wrongly positioned, the

carton is diverted to a holding area for investigation.

CUSTOMER APPLICATION

In the food-processing industry, packaged consumer products

require labelling – both for identification and for batch control

– before final packing. During confectionery production, sealed

cartons of bagged candy travel by conveyor from carton-

taping stations to a label printer-applicator, before passing to

the final packing area.

The printer-applicator, which is located at one side of the

conveyor, produces a continuous feed of printed labels from

roll-stock. As each carton passes the applicator head, the label-

stock advances, peeling a single label and applying it to the

side of the carton.

From time to time, misfeeds or malfunctions occur within the

printer-applicator, which consequently applies labels that are

either blank, illegible or wrongly positioned. Failure to detect

these errors results in unidentified or untraceable products

arriving at subsequent operations or, critically, at the

customer’s premises.

A highly reliable non-contact sensor system is needed. The

sensor must detect the alignment of labels and confirm the

presence of print markings as cartons leave the printer-

applicator, rejecting any defective cartons.

Contrinex’s Colour photoelectric sensors use energetic-diffuse

sensing to detect variations in target colour, to enable colour

sorting or colour control. Contrinex colour sensors feature five

selectable tolerance levels for each of three separate outputs,

which each can be set using a “teach-in” function to recognise

or ignore even the smallest variations of colour.

The Colour and Contrast sensors use the same rugged PBTP

housing (40 mm x 50 mm x 15 mm) with IP67 enclosure rating

and are available in cable or adjustable (0°, 45° or 90°)

connector versions.

Contrinex’s Contrast sensors offer exceptional performance for

detecting print marks in printing, labelling and packaging

applications. Using a narrowly focused light beam and RGB

(Red-Green-Blue light) emission technology, the contrast

sensor automatically selects the best emission colour during

the teach-in procedure.

Excellent contrast resolution, a high switching frequency (up

to 10 kHz) and five tolerance levels ensure accurate detection

and positioning, even when contrast differences are minimal.

The integral IO-Link interface can be used to reduce

changeover times through remote teach-in and

parameterisation. Other control functions, including

monitoring, diagnosis and switching timer adjustment are also

available using IO-Link.

.

INDUSTRY LEADING CONTRAST & COLOUR SENSORS

- EXCELLENCE IN DETECTING THE DIFFERENCE

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS