(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

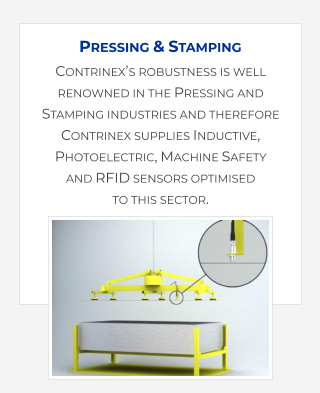

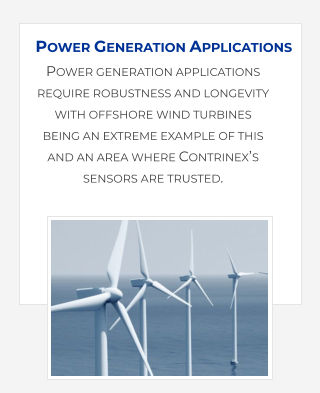

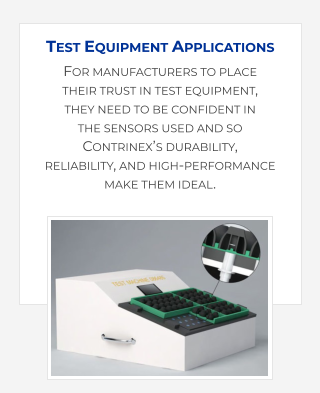

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

LESS HANDLING

ELIMINATE VISUAL INSPECTION

FEWER RETURNS

PROCESS VERIFICATION

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

The automotive industry demands parts that are verified to be

100% correct and therefore a supplier of injection moulded

parts trusts Contrinex inductives from their Extra Distance 500

Series to check that threaded inserts have been correctly

mounted inside moulded plastic parts.

CUSTOMER APPLICATION

To enable the fast screw assembly required by automotive

plants it is common to embed threaded inserts, typically made

of brass, into plastic mouldings.

These nut-like elements are crucial to ensuring the correct

final assembly process of the car and so the supplier must be

able to ensure they are all present. It is not uncommon for

automotive companies to return several days’ worth of

production parts to a supplier and levy substantial fines if even

a minor error is found.

The design of the moulded plastic parts which are used in

automotive air filtration systems is problematic because it

prevents visual checking the presence of the inserts and so a

reliable test mechanism had to be found.

CUSTOMER SOLUTION

Contrinex DW-AS-513-M30-002 Extra Distance inductives are

used in a checking fixture to detect if any inserts are missing

or incorrectly mounted. The solution exploits the unique

sensing capabilities of the Condist® technology in these 500

Series sensors, utilising their longer sensing distances and

better stability to environmental influences. The long

operating distance and high sensing stability enable the

detection of small inserts through a thick layer of plastic.

The test fixture is designed to accept a finished moulding and

is equipped with sensors at each of the insert locations. Each

sensor can detect the presence of the corresponding metal

insert through moulded plastic and so confirm compliance

with the specifications. The sensor’s PNP Normally Open

output provides a logical GO – NO GO feed to a micro-

controller.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE TESTING OF A RANGE OF

DIFFERENT-SIZED CONTAINERS

TESTING IS COMPLETED AT PRODUCTION-LINE SPEED

IMMEDIATE IDENTIFICATION OF MISSING CLOSURES

ELIMINATION OF MANUAL INSPECTION AND POTENTIAL BATCH

REJECTION

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 40MM

UNMATCHED COMBINATION OF 40MM SENSING DISTANCE IN

M30-DIAMETER DEVICE

CUSTOMER SOLUTION

Contrinex Extra Distance inductive sensors are ideal for this

application, with the M30-diameter units operating reliably at

sensing distances up to 40mm; a single sensor thus

accommodates the entire range of container heights. Robust

construction with chrome-plated brass bodies and PBTP

sensing faces ensures that these devices are suitable for a busy

production environment.

A single sensor, located immediately after the sealing station

and positioned directly above the production line, provides

reliable, repeatable and fast detection of the aluminium-foil

closures. With a switching frequency of up to 100Hz, this Extra

Distance unit is well suited for fast-moving production where

high-speed sensing is required.

This Contrinex inductive sensor has an industry-standard PNP

normally-open interface and an integral M12 cable connector,

allowing easy removal and replacement of individual sensors

for maintenance. Connection to the customer’s test

equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of 40mm sensing distance

in an M30-diameter device, the customer can now test the

entire range of containers without adjusting the sensor height

between batches. Contrinex Extra Distance inductive sensors

deliver exceptionally reliable test results at production-line

speed, without interruption.

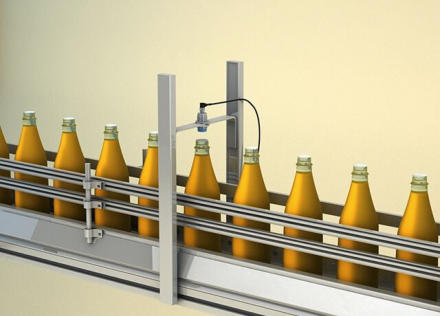

A food-processing plant trusts Contrinex’s sensors to help it

ensure plastic bottles, filled with liquid food products, are

hermetically sealed and its customers kept safe. Prior to the

containers being capped, a long-distance inductive sensor,

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

Aluminium-foil closures are commonly utilised as seals for

plastic containers filled with ketchup, mustard and other table

sauces. At a food-processing plant, closures are applied to

filled containers passing along an automated production line,

sealing the contents ready for capping and bulk packaging.

From time to time, equipment malfunctions can occur and

containers leave the sealing station without closures in place. If

unsealed containers are not detected prior to capping, entire

batches of product may require manual inspection, resulting

in lost production, down-time or potential rejection by

customers.

An in-line sensor system inspecting each container could

confirm the presence of a foil closure, rejecting any faulty

items. Each production line processes containers in batches.

The system must accommodate containers whose heights

vary by up to 20mm, without adjustment of sensors between

batches as successive batches may comprise containers of

differing sizes.

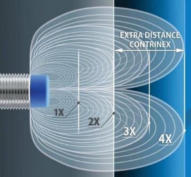

CONTRINEX IS RENOWNED FOR THE LONG SENSING DISTANCES OF ITS ‘500’ SERIES INDUCTIVE SENSORS -

THESE HIGH-PERFORMANCE SENSORS ARE AVAILABLE IN A WIDE VARIETY OF SIZES AND SPECIFICATIONS.

500 SERIES - ‘EXTENDED DISTANCE’ INDUCTIVES

500 SERIES ‘EXTENDED DISTANCE’ INDUCTIVES - EXTRA SENSING DISTANCES AT EXCELLENT PRICES

PRODUCT ADVANTAGES

EXCELLENT PRICE PERFORMANCE RATIO - EXTENDED SENSING

DISTANCE

A LARGE VARIETY OF PRODUCT SHAPES AND SIZES

A CHOICE OF SENSING DISTANCES (PLUS THE SISTER 600

SERIES OFFERING MORE AFFORDABLE SHORTER DISTANCES

AND THE MINIATURE FAMILY PROVIDING SMALLER SIZES)

DEVIATION IN OPERATING DISTANCE ≤2%

OUTSTANDING TEMPERATURE COMPENSATION

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Contrinex’s 500 Series of inductive sensors offer extended sensing range with excellent accuracy and exceptional reliability at an

economical price. Available in sizes from M8 to M30, plus C44 (40 x 40mm), with optional Ø 6.5 plain and 8 mm square-section

models, the 500 Series is ideal for position-sensing and presence-sensing applications in almost any industry.

Embeddable or non-embeddable variants are available, with either hard-wired, hermetically sealed connecting cables or integral

metal connectors. Highly repeatable results are supplied at operating temperatures between -25°C and +70°C and the included IO-

Link interface makes integration to Industry 4.0 easier and more powerful.

CUSTOMER VALUES

COST EFFECTIVE SOLUTION

NON CONTACT / NON-MARRING OF PACKAGING

ELIMINATES SHIPMENT OF DAMAGED OR SOILED PRODUCT

LONG PERFORMANCE HISTORY

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EASY MOUNTING AND ADJUSTMENT

SECURE DISTANCE BETWEEN MOVING OBJECT AND SENSOR

HIGH SWITCHING FREQUENCY

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

IO-LINK INTERFACE INCLUDED - IDEAL FOR INDUSTRY 4

CUSTOMER SOLUTION

Contrinex’s rugged Extra-Distance inductive sensors from the

‘500 Series’ are ideal for this application, being robust and

accurate. These highly reliable, IP67 rated, M30-diameter

sensors have a chrome-plated brass body with a PBTP sensing

face and vacuum-encapsulated electronics. Well suited to

operating in a hostile environment, the 3x sensing distance of

22mm enables fully contactless operation in this relatively high

speed packaging process.

A sensor array is placed over the conveyor and travel path of

the cardboard cases. For each lane of bottles in a case, an M30

diameter inductive sensor is mounted on the array. A non-

embeddable sensor is chosen as it most closely equates to the

size of the bottle cap and yields the greatest sensing distance

for the available target area and is sufficient to allow for minor

variations in the height of the case as it passes under the

sensor bridge. This not only ensures reliable sensing, but also

keeps the sensor at a safe distance from any impact, avoiding

consequent downtime, with the sensors interfaced with a

controller that makes the logical decision to accept the

package or reject and divert it.

A drinks producer needs to conduct a final,inspection check of

cases of bottles after the lid of the corrugated cardboard case

has been closed and sealed. A bottle count is performed by

verifying the position of bottle caps through layers of

cardboard at the top of each sealed case.

CUSTOMER APPLICATION

Bottles which are packed into corrugated cardboard cases

require both the verification of the placement and number of

bottles in the case, ideally after they have had their lids hot-

glued closed. A concern is that a bottle can break on impact

with the bottom of the case, contaminating the machinery

and subsequent packages. Bottles can also be absent or

wrongly positioned or a cap might be missing from a bottle.

Whilst a vision systems could be used, this would need to be

done before the lid of the case is closed, whereas verification of

the closed case would be preferable.

The absence of a bottle cap in a specified position is a good

indicator of a missing or shattered bottle and so the challenge

is therefore to detect bottle caps through multiple layers of

corrugated cardboard material of varying thickness and

density.

CUSTOMER VALUES

RUGGED INDUCTIVES ENSURE ACCURATE POSITIONING OF

MATERIALS, ELIMINATING FAULTS

MINIATURE EXTRA-DISTANCE SENSOR FITS SAFELY &

UNOBTRUSIVELY INTO IN-LINE WELDING STATION

IMMEDIATE AVAILABILITY OF DIVERSE SENSOR RANGE ENABLES

RAPID INCREASE IN PRODUCTION CAPACITY

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-&-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES

AND SENSING DISTANCES

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

OEM equipment builders have long relied on Contrinex as a

single source of high-performance and reliable sensors for

integration within their machines. The ability to supply the

sensors from stock was also essential in this instance, as the

machine was built to manufacture essential N95 face masks.

The sensors synchronise material feeds in the machine during

the assembly process and ensure the part-completed mask is

positioned correctly. Designers specified rugged inductive

sensors with IO-Link connectivity to prevent costly machine

malfunctions.

CUSTOMER APPLICATION

Reliability is essential in automated production, and nowhere

more than in the hard-pressed healthcare supply sector. At the

time of the global COVID-19 crisis, OEM equipment builders

rushed to increase capacity for producing personal protective

equipment (PPE). Manufacturers of N95 face masks, a high-

volume item of PPE, faced unprecedented demand worldwide.

While a single N95 mask is a relatively low-cost item, fast-

moving production lines mean that any interruption to

continuous operation is disproportionately expensive. Machine

malfunctions not only cause lost production time but also

result in costly manual intervention, and must be prevented.

Purpose-built machines for manufacturing N95 masks must

dovetail several material feeds prior to assembly; they must

also ensure that part-completed masks are positioned

correctly during the process. Successive workstations

incorporate multiple position-sensing and presence-detection

sensors that monitor the status of material feeds and cutter

position, as well as checking part alignment for welding and

printing. It is highly desirable to source these devices from a

single manufacturer, minimizing spares inventory and

ensuring a common interface throughout an entire machine.

CUSTOMER SOLUTION

OEM designers specified rugged inductive sensors from the

Contrinex Basic and Miniature ranges. Not only did the

available selection match the functional requirement exactly,

the immediate availability of all the required devices from

stock eliminated delays in ramping up capacity. All the

specified sensors feature IO-Link connectivity, providing a

single, industry-standard interface to the machine control

system.

Contrinex inductive sensors are designed with the needs of

OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. With a sensing distance of

4 mm, the two metal-cased M12 sensors used to monitor the

positions of the steel fabric cutter and the printing head are

robust and reliable. The M8 device that detects the feed

position of the aluminium fixing strip has a V2A stainless-steel

housing and an extended sensing distance of 2 mm, fitting

snugly in the limited space available.

The extra-distance miniature M5 sensor fitted at the welding

station has a nickel-silver housing and was selected because of

its 2.5-mm sensing distance, eliminating any danger of

accidental collision during operation. Connection to all the

specified sensors is via a PVC-sheathed cable with a 3-pin

connector or 2-metre flying lead; alternative lengths are

available.

These highly versatile sensors meet designers’ needs for

trouble-free operation using sensors from a single

manufacturer. The solution is highly reliable, cost-effective

and, critically, available without delay, allowing the immediate

increase in machine-building capacity required by the OEM

customer.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS CIRCUIT-BOARD DETECTION

IS HIGHLY RELIABLE

MINIMAL REPLACEMENT SENSOR COSTS AS A RESULT OF

SENSOR’S LONG SERVICE LIFE

LOW RISK OF THERMAL OR MECHANICAL DAMAGE BECAUSE OF

EXTENDED OPERATING DISTANCE

PRODUCT ADVANTAGES

SENSOR PERFORMANCE UNAFFECTED BY ELEVATED

TEMPERATURES

CONDIST® TECHNOLOGY OF EXTRA DISTANCE FAMILY

DELIVERS BEST-IN-CLASS OPERATING DISTANCES

EXTENDED SENSING RANGE ≤ 10MM

RUGGED INDUCTIVE SENSOR WITH METAL HOUSING

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

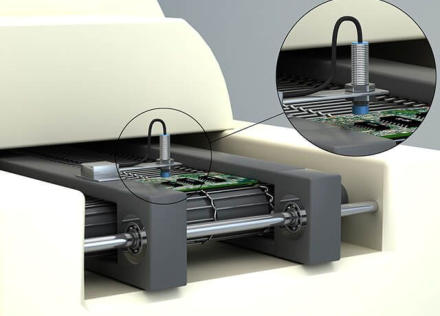

A manufacturer of computer Printed Circuit Boards (PCBs)

uses presence detection immediately after a soldering reflow

process to trigger a subsequent operation. A long-distance

inductive sensor is mounted above the exit conveyor of the

reflow oven and detects each motherboard as it passes out of

the oven. The customer’s control system accepts the sensor’s

switched output, initiating the next process stage.

CUSTOMER APPLICATION

Reflow soldering ovens are an essential part of the electronic

assemble process, being used to secure components in place

on printed circuit boards. PCBs which have had solder paste

screen-printed onto them are populated with electronic

components and connectors before being conveyed into a

reflow oven. As the PCB is conveyed through the oven, the

temperature increases progressively according to a

predetermined thermal profile which melts the solder paste so

that it flows around and secures the components, as well as

ensuring a robust electrical connection.

As each PCB leaves the oven, a sensor must trigger the

factory’s control system to activate an automated transfer

mechanism to move the board to the next processing stage.

The ambient temperature of 80°C immediately adjacent to the

exit of the oven was causing an unacceptable rate of failure in

other manufacturer’s sensors and so Contrinex was

approached to see if its sensors could operate with total

reliability.

CUSTOMER SOLUTION

Contrinex’s 500 series of inductive sensors which provide

extended sensing distances were ideal for this application.

They were able to detect the metal within the PCB and also

allow sufficient space for the PCBs with tall components to

pass underneath. The longer-distance sensing also enables the

sensor to be positioned further away from the heat being

radiated off the hot boards.

Best-in-class operating distances, vacuum-encapsulated

electronics and excellent resistance to thermal shock and

vibration from Contrinex’s Condist® technology enable these

sensors to provide a continuous 70°C temperature rating.

The inductive sensors are mounted vertically on steel brackets

attached to the exterior of the reflow ovens. They are

positioned 10mm above the PCBs and their M12-threaded

metal housing enables easy adjustment. The 500 series

sensors proved to be reliable even in the elevated ambient

temperatures around the reflow oven, without needing to use

more expensive specialised high-temperature sensors, an area

in which Contrinex also excels, offering inductive sensors rated

to operate in temperatures up to 230°C.

The factory’s control system required an NPN sensor with a

normally open configuration and other than fitting protective

sheathing over the sensor’s PVC cable, no additional electrical

or mechanical protection was required despite the adverse

operating conditions.

Previously, sensors from other manufacturers did not detect

boards reliably and had unacceptably short service lives,

causing frequent interruptions to production. Whilst the

sensors were not particularly expensive, the cost of engineers

replacing them and interruptions to the manufacturing

process was high. The switch to Contrinex inductive sensors

provided a reliable sensing solution enabling the customer to

achieve the level of machine availability and effectiveness,

OEE, that they desired. The total cost of ownership was

extremely attractive because the 500 Series extended range

inductive sensor cost less than the cost of two of the

competitor's sensors.

CUSTOMER VALUES

SIMPLE SENSOR SYSTEM ELIMINATES MANUAL CHECKING

EXTENDED SENSING RANGE ALLOWS ACCURATE, CONTACTLESS

OPERATION

ROBUST CONSTRUCTION WITHSTANDS CONTAMINATION AND

WATER INGRESS

HIGHEST PRECISION, TEMPERATURE STABILITY AND RELIABILITY

PRODUCT ADVANTAGES

22MM SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

HIGH RESISTANCE TO HARSH OPERATING CONDITIONS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

IO-LINK INTERFACE INCLUDED - IDEAL FOR INDUSTRY 4

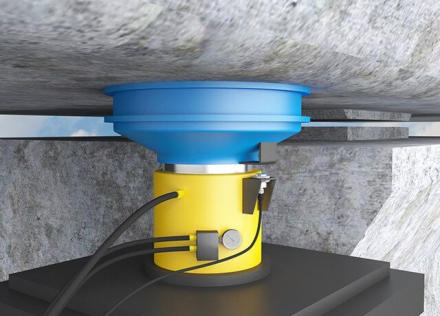

CUSTOMER SOLUTION

Rugged Extra-Distance inductive sensors from Contrinex’s 500

Series are ideal for this application. Highly reliable and rated to

IP67, these units are robust and accurate. A one-piece M30-

diameter chrome-plated brass body with PBTP sensing face

and vacuum-encapsulated electronics make this device well

suited to the hostile environment, and the sensing distance of

22mm allows fully contactless operation.

On each jack, a single sensor is fitted on a metal bracket that is

welded to the side of the cylinder; a bearing plate, mounted on

the end of the ram, distributes the load onto the bridge

section. During operation, the ram extends, lifting the section;

when it reaches the desired height, the sensor detects the

position of a small metal target mounted on the bearing plate,

halting the ram.

The sensor is configured with an industry-standard PNP

normally-open interface, and connection to the jack’s

hydraulic control system is via an integral M12 connector and

PVC-sheathed cable; this allows easy removal and

replacement during routine maintenance. The sensor is

impervious to water ingress, mud and dirt; reliability has been

excellent. Contrinex inductive sensors deliver a cost-effective

solution that satisfies the customer’s requirements for a

simple, fit-and-forget system.

Modern road bridges are typically constructed using mobile

cranes to lift prefabricated bridge beam onto support

columns. Heavy-duty hydraulic cylinders support the ends of

each section to enable accurate height adjustment prior to

final positioning. Engineers require rugged sensor systems

that detect the position of each cylinder accurately. These

sensors need to be mechanically robust and must withstand

harsh outdoors conditions.

CUSTOMER APPLICATION

A specialist lifting company uses heavy-duty hydraulic

cylinder-jacks to position prefabricated bridge sections during

roadway construction. A bridge single section requires up to

20 jacks for accurate positioning, with each jack having a

capacity up to 1,000 tons with a stroke up to 30mm (1.25 in).

On-site conditions are harsh with cylinders exposed to water,

mud and dirt, and may also be subject to mechanical shock

and vibration.

The company requires rugged sensors that operate reliably

and accurately in the demanding environment. Historically,

engineers checked the position of each cylinder manually; this

was both time-consuming and subject to human error.

Previously trialled sensors were insufficiently robust,

necessitating frequent adjustment or replacement, and had

inadequate sensing distances.

A simple, contactless system must provide fit-and-forget

operation with extended maintenance intervals. The sensors

need to be mechanically robust and must withstand

prolonged exposure to the harsh outdoor conditions of a

construction site. An industry-standard interface is highly

desirable to avoid the need for specialised control systems.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

CUSTOMER VALUES

LESS HANDLING

ELIMINATE VISUAL INSPECTION

FEWER RETURNS

PROCESS VERIFICATION

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

The automotive industry demands parts that are verified to be

100% correct and therefore a supplier of injection moulded

parts trusts Contrinex inductives from their Extra Distance 500

Series to check that threaded inserts have been correctly

mounted inside moulded plastic parts.

CUSTOMER APPLICATION

To enable the fast screw assembly required by automotive

plants it is common to embed threaded inserts, typically made

of brass, into plastic mouldings.

These nut-like elements are crucial to ensuring the correct

final assembly process of the car and so the supplier must be

able to ensure they are all present. It is not uncommon for

automotive companies to return several days’ worth of

production parts to a supplier and levy substantial fines if even

a minor error is found.

The design of the moulded plastic parts which are used in

automotive air filtration systems is problematic because it

prevents visual checking the presence of the inserts and so a

reliable test mechanism had to be found.

CUSTOMER SOLUTION

Contrinex DW-AS-513-M30-002 Extra Distance inductives are

used in a checking fixture to detect if any inserts are missing

or incorrectly mounted. The solution exploits the unique

sensing capabilities of the Condist® technology in these 500

Series sensors, utilising their longer sensing distances and

better stability to environmental influences. The long

operating distance and high sensing stability enable the

detection of small inserts through a thick layer of plastic.

The test fixture is designed to accept a finished moulding and

is equipped with sensors at each of the insert locations. Each

sensor can detect the presence of the corresponding metal

insert through moulded plastic and so confirm compliance

with the specifications. The sensor’s PNP Normally Open

output provides a logical GO – NO GO feed to a micro-

controller.

CLICK ON AN IMAGE TO VIEW THE BROCHURE,

READ APPLICATION EXAMPLES BELOW, CLICK

HERE TO VIEW THIS SENSOR ON CONTRINEX’S

WEBSITE, OR CALL US TO HELP GUIDE YOU

THROUGH SELECTION, ANSWER QUESTIONS, OR

TO HELP YOU #MAKESENSEOFSENSORS:

500 SERIES - ‘EXTENDED

DISTANCE’ INDUCTIVES

CONTRINEX IS RENOWNED FOR THE LONG SENSING

DISTANCES OF ITS ‘500’ SERIES INDUCTIVE SENSORS -

THESE HIGH-PERFORMANCE SENSORS ARE AVAILABLE

IN A WIDE VARIETY OF SIZES AND SPECIFICATIONS.

OEM equipment builders have long relied on Contrinex as a

single source of high-performance and reliable sensors for

integration within their machines. The ability to supply the

sensors from stock was also essential in this instance, as the

machine was built to manufacture essential N95 face masks.

The sensors synchronise material feeds in the machine during

the assembly process and ensure the part-completed mask is

positioned correctly. Designers specified rugged inductive

sensors with IO-Link connectivity to prevent costly machine

malfunctions.

CUSTOMER APPLICATION

Reliability is essential in automated production, and nowhere

more than in the hard-pressed healthcare supply sector. At the

time of the global COVID-19 crisis, OEM equipment builders

rushed to increase capacity for producing personal protective

equipment (PPE). Manufacturers of N95 face masks, a high-

volume item of PPE, faced unprecedented demand worldwide.

While a single N95 mask is a relatively low-cost item, fast-

moving production lines mean that any interruption to

continuous operation is disproportionately expensive. Machine

malfunctions not only cause lost production time but also

result in costly manual intervention, and must be prevented.

Purpose-built machines for manufacturing N95 masks must

dovetail several material feeds prior to assembly; they must

also ensure that part-completed masks are positioned

correctly during the process. Successive workstations

incorporate multiple position-sensing and presence-detection

sensors that monitor the status of material feeds and cutter

position, as well as checking part alignment for welding and

printing. It is highly desirable to source these devices from a

single manufacturer, minimizing spares inventory and

ensuring a common interface throughout an entire machine.

CUSTOMER VALUES

RELIABLE, REPEATABLE IN-LINE TESTING OF A RANGE OF

DIFFERENT-SIZED CONTAINERS

TESTING IS COMPLETED AT PRODUCTION-LINE SPEED

IMMEDIATE IDENTIFICATION OF MISSING CLOSURES

ELIMINATION OF MANUAL INSPECTION AND POTENTIAL BATCH

REJECTION

PRODUCT ADVANTAGES

EXTENDED SENSING DISTANCES UP TO 40MM

UNMATCHED COMBINATION OF 40MM SENSING DISTANCE IN

M30-DIAMETER DEVICE

CUSTOMER SOLUTION

Contrinex Extra Distance inductive sensors are ideal for this

application, with the M30-diameter units operating reliably at

sensing distances up to 40mm; a single sensor thus

accommodates the entire range of container heights. Robust

construction with chrome-plated brass bodies and PBTP

sensing faces ensures that these devices are suitable for a busy

production environment.

A single sensor, located immediately after the sealing station

and positioned directly above the production line, provides

reliable, repeatable and fast detection of the aluminium-foil

closures. With a switching frequency of up to 100Hz, this Extra

Distance unit is well suited for fast-moving production where

high-speed sensing is required.

This Contrinex inductive sensor has an industry-standard PNP

normally-open interface and an integral M12 cable connector,

allowing easy removal and replacement of individual sensors

for maintenance. Connection to the customer’s test

equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of 40mm sensing distance

in an M30-diameter device, the customer can now test the

entire range of containers without adjusting the sensor height

between batches. Contrinex Extra Distance inductive sensors

deliver exceptionally reliable test results at production-line

speed, without interruption.

A food-processing plant trusts Contrinex’s sensors to help it

ensure plastic bottles, filled with liquid food products, are

hermetically sealed and its customers kept safe. Prior to the

containers being capped, a long-distance inductive sensor,

positioned directly over the packaging line confirms the

presence of an aluminium-foil seal over the top of every

container.

CUSTOMER APPLICATION

Aluminium-foil closures are commonly utilised as seals for

plastic containers filled with ketchup, mustard and other table

sauces. At a food-processing plant, closures are applied to

filled containers passing along an automated production line,

sealing the contents ready for capping and bulk packaging.

From time to time, equipment malfunctions can occur and

containers leave the sealing station without closures in place. If

unsealed containers are not detected prior to capping, entire

batches of product may require manual inspection, resulting

in lost production, down-time or potential rejection by

customers.

An in-line sensor system inspecting each container could

confirm the presence of a foil closure, rejecting any faulty

items. Each production line processes containers in batches.

The system must accommodate containers whose heights

vary by up to 20mm, without adjustment of sensors between

batches as successive batches may comprise containers of

differing sizes.

CUSTOMER VALUES

RUGGED INDUCTIVES ENSURE ACCURATE POSITIONING OF

MATERIALS, ELIMINATING FAULTS

MINIATURE EXTRA-DISTANCE SENSOR FITS SAFELY &

UNOBTRUSIVELY INTO IN-LINE WELDING STATION

IMMEDIATE AVAILABILITY OF DIVERSE SENSOR RANGE ENABLES

RAPID INCREASE IN PRODUCTION CAPACITY

PROVEN TECHNOLOGY ENSURES HIGHLY RELIABLE FIT-&-

FORGET OPERATION WITH NO MANUAL INTERVENTION

PRODUCT ADVANTAGES

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

DIVERSE PORTFOLIO OFFERS EXCEPTIONAL RANGE OF SIZES

AND SENSING DISTANCES

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Customer Solution

OEM designers specified rugged inductive sensors from the

Contrinex Basic and Miniature ranges. Not only did the

available selection match the functional requirement exactly,

the immediate availability of all the required devices from

stock eliminated delays in ramping up capacity. All the

specified sensors feature IO-Link connectivity, providing a

single, industry-standard interface to the machine control

system.

Contrinex inductive sensors are designed with the needs of

OEMs and system integrators in mind and provide an

unobtrusive fit-and-forget solution. With a sensing distance of

4 mm, the two metal-cased M12 sensors used to monitor the

positions of the steel fabric cutter and the printing head are

robust and reliable. The M8 device that detects the feed

position of the aluminium fixing strip has a V2A stainless-steel

housing and an extended sensing distance of 2 mm, fitting

snugly in the limited space available.

The extra-distance miniature M5 sensor fitted at the welding

station has a nickel-silver housing and was selected because of

its 2.5-mm sensing distance, eliminating any danger of

accidental collision during operation. Connection to all the

specified sensors is via a PVC-sheathed cable with a 3-pin

connector or 2-metre flying lead; alternative lengths are

available.

These highly versatile sensors meet designers’ needs for

trouble-free operation using sensors from a single

manufacturer. The solution is highly reliable, cost-effective

and, critically, available without delay, allowing the immediate

increase in machine-building capacity required by the OEM

customer.

500 SERIES ‘EXTENDED DISTANCE’

INDUCTIVES - EXTRA SENSING DISTANCES

AT EXCELLENT PRICES

PRODUCT ADVANTAGES

EXCELLENT PRICE PERFORMANCE RATIO - EXTENDED SENSING

DISTANCE

A LARGE VARIETY OF PRODUCT SHAPES AND SIZES

A CHOICE OF SENSING DISTANCES (PLUS THE SISTER 600

SERIES OFFERING MORE AFFORDABLE SHORTER DISTANCES

AND THE MINIATURE FAMILY PROVIDING SMALLER SIZES)

DEVIATION IN OPERATING DISTANCE ≤2%

OUTSTANDING TEMPERATURE COMPENSATION

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Contrinex’s 500 Series of inductive sensors offer extended

sensing range with excellent accuracy and exceptional reliability

at an economical price. Available in sizes from M8 to M30, plus

C44 (40 x 40mm), with optional Ø 6.5 plain and 8 mm square-

section models, the 500 Series is ideal for position-sensing and

presence-sensing applications in almost any industry.

Embeddable or non-embeddable variants are available, with

either hard-wired, hermetically sealed connecting cables or

integral metal connectors. Highly repeatable results are

supplied at operating temperatures between -25°C and +70°C

and the included IO-Link interface makes integration to

Industry 4.0 easier and more powerful.

CUSTOMER VALUES

SIMPLE SENSOR SYSTEM ELIMINATES MANUAL CHECKING

EXTENDED SENSING RANGE ALLOWS ACCURATE, CONTACTLESS

OPERATION

ROBUST CONSTRUCTION WITHSTANDS CONTAMINATION AND

WATER INGRESS

HIGHEST PRECISION, TEMPERATURE STABILITY AND RELIABILITY

PRODUCT ADVANTAGES

22MM SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

HIGH RESISTANCE TO HARSH OPERATING CONDITIONS

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

IO-LINK INTERFACE INCLUDED - IDEAL FOR INDUSTRY 4

CUSTOMER SOLUTION

Rugged Extra-Distance inductive sensors from Contrinex’s 500

Series are ideal for this application. Highly reliable and rated to

IP67, these units are robust and accurate. A one-piece M30-

diameter chrome-plated brass body with PBTP sensing face

and vacuum-encapsulated electronics make this device well

suited to the hostile environment, and the sensing distance of

22mm allows fully contactless operation.

On each jack, a single sensor is fitted on a metal bracket that is

welded to the side of the cylinder; a bearing plate, mounted on

the end of the ram, distributes the load onto the bridge

section. During operation, the ram extends, lifting the section;

when it reaches the desired height, the sensor detects the

position of a small metal target mounted on the bearing plate,

halting the ram.

The sensor is configured with an industry-standard PNP

normally-open interface, and connection to the jack’s

hydraulic control system is via an integral M12 connector and

PVC-sheathed cable; this allows easy removal and

replacement during routine maintenance. The sensor is

impervious to water ingress, mud and dirt; reliability has been

excellent. Contrinex inductive sensors deliver a cost-effective

solution that satisfies the customer’s requirements for a

simple, fit-and-forget system.

Modern road bridges are typically constructed using mobile

cranes to lift prefabricated bridge beam onto support

columns. Heavy-duty hydraulic cylinders support the ends of

each bridge section to enable accurate height adjustment

prior to final positioning. Engineers require rugged sensor

systems that detect the position of each cylinder accurately.

These sensors need to be mechanically robust and must

withstand harsh outdoors conditions.

CUSTOMER APPLICATION

A specialist lifting company uses heavy-duty hydraulic

cylinder-jacks to position prefabricated bridge sections during

roadway construction. A bridge single section requires up to

20 jacks for accurate positioning, with each jack having a

capacity up to 1,000 tons with a stroke up to 30mm (1.25 in). On

site conditions are harsh with cylinders exposed to water, mud

and dirt, and may also be subject to mechanical shock and

vibration.

The company requires rugged sensors that operate reliably

and accurately in the demanding environment. Historically,

engineers checked the position of each cylinder manually; this

was both time-consuming and subject to human error.

Previously trialled sensors were insufficiently robust,

necessitating frequent adjustment or replacement, and had

inadequate sensing distances.

A simple, contactless system must provide fit-and-forget

operation with extended maintenance intervals. The sensors

need to be mechanically robust and must withstand

prolonged exposure to the harsh outdoor conditions of a

construction site. An industry-standard interface is highly

desirable to avoid the need for specialised control systems.

CUSTOMER VALUES

UNINTERRUPTED PRODUCTION AS CIRCUIT-BOARD DETECTION

IS HIGHLY RELIABLE

MINIMAL REPLACEMENT SENSOR COSTS AS A RESULT OF

SENSOR’S LONG SERVICE LIFE

LOW RISK OF THERMAL OR MECHANICAL DAMAGE BECAUSE OF

EXTENDED OPERATING DISTANCE

PRODUCT ADVANTAGES

SENSOR PERFORMANCE UNAFFECTED BY ELEVATED

TEMPERATURES

CONDIST® TECHNOLOGY OF EXTRA DISTANCE FAMILY

DELIVERS BEST-IN-CLASS OPERATING DISTANCES

EXTENDED SENSING RANGE ≤ 10MM

RUGGED INDUCTIVE SENSOR WITH METAL HOUSING

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

A manufacturer of computer Printed Circuit Boards (PCBs)

uses presence detection immediately after a soldering reflow

process to trigger a subsequent operation. A long-distance

inductive sensor is mounted above the exit conveyor of the

reflow oven and detects each motherboard as it passes out of

the oven. The customer’s control system accepts the sensor’s

switched output, initiating the next process stage.

CUSTOMER APPLICATION

Reflow soldering ovens are an essential part of the electronic

assemble process, being used to secure components in place

on printed circuit boards. PCBs which have had solder paste

screen-printed onto them are populated with electronic

components and connectors before being conveyed into a

reflow oven. As the PCB is conveyed through the oven, the

temperature increases progressively according to a

predetermined thermal profile which melts the solder paste so

that it flows around and secures the components, as well as

ensuring a robust electrical connection.

As each PCB leaves the oven, a sensor must trigger the

factory’s control system to activate an automated transfer

mechanism to move the board to the next processing stage.

The ambient temperature of 80°C immediately adjacent to the

exit of the oven was causing an unacceptable rate of failure in

other manufacturer’s sensors and so Contrinex was

approached to see if its sensors could operate with total

reliability.

CUSTOMER SOLUTION

Contrinex’s 500 series of inductive sensors which provide

extended sensing distances were ideal for this application.

They were able to detect the metal within the PCB and also

allow sufficient space for the PCBs with tall components to

pass underneath. The longer-distance sensing also enables the

sensor to be positioned further away from the heat being

radiated off the hot boards.

Best-in-class operating distances, vacuum-encapsulated

electronics and excellent resistance to thermal shock and

vibration from Contrinex’s Condist® technology enable these

sensors to provide a continuous 70°C temperature rating.

The inductive sensors are mounted vertically on steel brackets

attached to the exterior of the reflow ovens. They are

positioned 10mm above the PCBs and their M12-threaded

metal housing enables easy adjustment. The 500 series

sensors proved to be reliable even in the elevated ambient

temperatures around the reflow oven, without needing to use

more expensive specialised high-temperature sensors, an area

in which Contrinex also excels, offering inductive sensors rated

to operate in temperatures up to 230°C.

The factory’s control system required an NPN sensor with a

normally open configuration and other than fitting protective

sheathing over the sensor’s PVC cable, no additional electrical

or mechanical protection was required despite the adverse

operating conditions.

Previously, sensors from other manufacturers did not detect

boards reliably and had unacceptably short service lives,

causing frequent interruptions to production. Whilst the

sensors were not particularly expensive, the cost of engineers

replacing them and interruptions to the manufacturing

process was high. The switch to Contrinex inductive sensors

provided a reliable sensing solution enabling the customer to

achieve the level of machine availability and effectiveness,

OEE, that they desired. The total cost of ownership was

extremely attractive because the 500 Series extended range

inductive sensor cost less than the cost of two of the

competitor's sensors.

CUSTOMER VALUES

COST EFFECTIVE SOLUTION

NON CONTACT / NON-MARRING OF PACKAGING

ELIMINATES SHIPMENT OF DAMAGED OR SOILED PRODUCT

LONG PERFORMANCE HISTORY

PRODUCT ADVANTAGES

LONG OPERATING DISTANCE (3X STANDARD VALUE)

EASY MOUNTING AND ADJUSTMENT

SECURE DISTANCE BETWEEN MOVING OBJECT AND SENSOR

HIGH SWITCHING FREQUENCY

EXCELLENT SENSING STABILITY ON SMALL & THIN TARGETS

IO-LINK INTERFACE INCLUDED - IDEAL FOR INDUSTRY 4

CUSTOMER SOLUTION

Contrinex’s rugged Extra-Distance inductive sensors from the

‘500 Series’ are ideal for this application, being robust and

accurate. These highly reliable, IP67 rated, M30-diameter

sensors have a chrome-plated brass body with a PBTP sensing

face and vacuum-encapsulated electronics. Well suited to

operating in a hostile environment, the 3x sensing distance of

22mm enables fully contactless operation in this relatively high

speed packaging process.

A sensor array is placed over the conveyor and travel path of

the cardboard cases. For each lane of bottles in a case, an M30

diameter inductive sensor is mounted on the array. A non-

embeddable sensor is chosen as it most closely equates to the

size of the bottle cap and yields the greatest sensing distance

for the available target area and is sufficient to allow for minor

variations in the height of the case as it passes under the

sensor bridge. This not only ensures reliable sensing, but also

keeps the sensor at a safe distance from any impact, avoiding

consequent downtime, with the sensors interfaced with a

controller that makes the logical decision to accept the

package or reject and divert it.

A drinks producer needs to conduct a final,inspection check of

cases of bottles after the lid of the corrugated cardboard case

has been closed and sealed. A bottle count is performed by

verifying the position of bottle caps through layers of

cardboard at the top of each sealed case.

CUSTOMER APPLICATION

Bottles which are packed into corrugated cardboard cases

require both the verification of the placement and number of

bottles in the case, ideally after they have had their lids hot-

glued closed. A concern is that a bottle can break on impact

with the bottom of the case, contaminating the machinery

and subsequent packages. Bottles can also be absent or

wrongly positioned or a cap might be missing from a bottle.

Whilst a vision systems could be used, this would need to be

done before the lid of the case is closed, whereas verification of

the closed case would be preferable..

The absence of a bottle cap in a specified position is a good

indicator of a missing or shattered bottle and so the challenge

is therefore to detect bottle caps through multiple layers of

corrugated cardboard material of varying thickness and

density.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS