(0121) 58 222 58 SALES@PLUSAUTOMATION.CO.UK

© 2021 - PLUS AUTOMATION LIMITED®

HELPING YOU #MAKE SENSE OF SENSORS

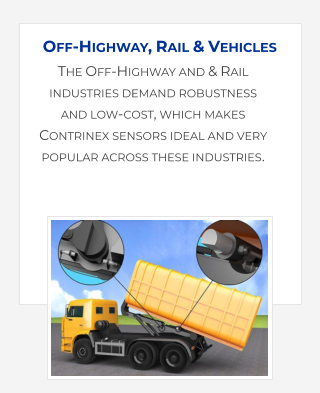

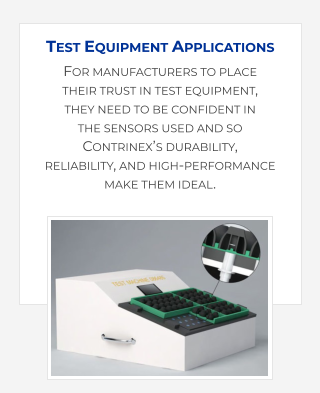

EXAMPLE APPLICATIONS

TO ILLUSTRATE THE WIDE-VARIETY OF APPLICATIONS SOLVED USING CONTRINEX SENSORS, WE HAVE POSTED A LARGE SELECTION OF EXAMPLE APPLICATIONS WHICH CAN BE SEEN BY CLICKING ON AN IMAGE. BELOW ARE A SELECTION OF SOME OF THESE APPLICATIONS:

CUSTOMER VALUES

SAFE, RELIABLE PERFORMANCE IN A DEMANDING OUTDOOR

ENVIRONMENT

NO LIKELIHOOD OF ACCIDENTAL DAMAGE ARISING IN

OPERATION

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

CORROSION-RESISTANT STAINLESS-STEEL SENSOR RATED TO

IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

CUSTOMER SOLUTION

Contrinex inductive sensors are robust, reliable and offer

extended sensing distances; the Full Inox Extreme range is

ideal for this application. A one-piece M30-diameter stainless-

steel body and vacuum-encapsulated electronics make this

device particularly suitable for the mechanically demanding

environment, and the sensing distance of 20mm eliminates

any possibility of accidental collision in operation.

A metal bracket is mounted externally on the actuating

mechanism for the upper forks; the embeddable sensor is

mounted immediately adjacent to one of the forks and detects

the position of the actuating arm as it drives the fork into the

vertical position. The AISI 303/V2A stainless-steel housing and

sensing face are corrosion-resistant and impervious to water

ingress; the sensor is IP68- and IP69K-rated.

Configured with an industry-standard PNP normally-open

interface, the Contrinex M30 Extreme sensor connects to the

forklift’s lower-fork tilt-control systems via a flexible PUR-

sheathed cable. A sealed cable entry ensures fit-and-forget

capability during extended periods of operation in an outdoor

environment.

The Full Inox inductive sensor detects the vertical position of

the forklift’s upper forks effectively and repeatably, ensuring

safe, reliable operation of the unloading system. Contrinex

inductive sensors deliver a cost-effective solution that satisfies

the customer’s requirements for extreme robustness and

extended sensing distance.

A container manufacturer uses a modified forklift, fitted with

two sets of forks, for unloading bulk cargo. The lower forks

support the container while the upper forks control the lid.

When unloading, the lid opens and the lower forks rotate,

tipping out the contents. A robust inductive sensor senses the

position of the lid, ensuring it opens fully before emptying.

CUSTOMER APPLICATION

Containers are often used when transporting bulk cargo,

including wood chip and biomass, by rail. A manufacturer of

bulk-cargo containers has developed an innovative unloading

system that uses only a modified forklift, eliminating the need

for specialist handling equipment.

The forklift has two pairs of lifting forks. The main forks,

mounted conventionally, support the weight of the container

as it is unloaded from a freight wagon; a second pair, mounted

vertically above the lower pair, opens and closes the lid of the

container. During opening, the upper forks lift the lid a short

distance before tilting it vertically, leaving the top of the

container completely unobstructed.

The lower forks then rotate about a horizontal axis, tilting the

container end-over-end and tipping the contents out. A robust

and reliable sensor system is required to detect the vertical

position of the lid before rotation begins. An extended sensing

distance is essential to eliminate the possibility of mechanical

damage.

CUSTOMER VALUES

HIGHLY COST EFFECTIVE SOLUTION - SUBSTANTIALLY LOWER

COST THAN OTHER DOUBLE-SHEET DETECTION SOLUTIONS

SIMPLE SETUP AND USE

ELIMINATES MACHINE JAMS, BREAKAGE OF TOOLING AND SO

ELIMINATES PRODUCTION DOWNTIME

CORROSION-RESISTANT SENSORS WITHSTAND CLEANING

PRODUCT ADVANTAGES

UNIQUE TECHNOLOGY DEFIES LIMITS OF TRADITIONAL

INDUCTIVE SENSOR TECHNOLOGY

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K STAINLESS-STEEL RATED HOUSING

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

A manufacturer of metal cans needs to ensure that the press

that applies and crimps the bottom onto the can body is fed

with only one bottom. Therefore a fast, non-contact and robust

checking mechanism is required.

CUSTOMER APPLICATION

A conveyor with a stainless-steel glide plate backed by a

permanent magnet ensures that the can bottoms travel

perfectly flat on the belt which transports them to the

assembly stage. If double-bottoms are fed into the assembly

stage, damage can be done to the press, tools can be broken,

and even the press becoming jammed will cause production

downtime.

To check that only one bottom is being fed to the assembly

stage whilst they are attached magnetically to the fast-moving

belt, requires a non-contact sensing solution. The thin gauge

of steel used to produce the can bottoms (~0.33 mm thick) is

too small for the customer’s normal automatic double-sheet

detector to work reliably.

CUSTOMER SOLUTION

Contrinex’s Extreme 700 Series sensors provide a robust and

simple, cost effective solution. They utilise their Condet®

technology to detect the mass of a target by inducing a

voltage in it, whereas a traditional inductive sensor would

induce the voltage only in the target’s surface.

The stainless-steel bodied sensor (DW-Ax-70X-M12) is mounted

approximately 4 – 5 mm above the dome of a can bottom. On

its own, the 0.33mm thick steel doom presents insufficient

mass to switch the sensor at this distance, however the

presence of a second bottom piece increases target mass

sufficiently to switch the sensor.

The inductive sensor triggers a rejection shoot whenever two

bottoms are detected as being stacked together and so

provide a robust and reliable system to protect the assembly

press.

CUSTOMER VALUES

COST SAVING DUE TO REDUCED DOWNTIME CAUSED BY

SENSOR DAMAGE AND REPLACEMENT

SAFE, RELIABLE PERFORMANCE IN A DEMANDING

ENVIRONMENT FOR INCREASED PROCESS SECURITY

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

MECHANICALLY RUGGED, CORROSION-RESISTANT STAINLESS-

STEEL SENSOR RATED TO IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

FACTOR 1: IDENTICAL OPERATING DISTANCES ON STEEL AND

ALUMINIUM

CUSTOMER SOLUTION

Contrinex’s DW-AS-703-M30-002 inductive sensor is ideal for

this application. The 700 Series sensor’s long sensing distances

(20 mm in this case) detect equally well on both steel and

aluminium, which is often called ‘factor 1’ sensing.

The sensor selected detects the absence or presence of a

model-dependent metal part that identifies the model. If the

wrong model is identified, an alarm is generated to warn the

operator.

The Condet detection technology protects it from

environmental and material influences. and its all-metal, AISI

303/V2A stainless-steel housing and sensing face protect it

from corrosion and water ingress.

The 700 series of inductive sensors are much more resistant to

mechanical stresses than conventional sensors which makes

them ideal for this application since the process involves the

movement of large metal parts.

The sensor used for identification should be rugged enough to

withstand heavy impacts as the loading process is performed

manually by an operator, so movements and positions are

imprecise, while mechanical shocks to the sensor can be

expected and a long sensing distance is required.

.

An automotive manufacturer uses simple, low-cost inductive

sensors to identify which style of chassis it receives in the body

shop, to define what further processing should take place.

CUSTOMER APPLICATION

The customer manufactures a wide range of vehicles and so as

each body arrives at the body shop, operators use pulleys and

clamps to lift it onto the line. Since the same body shop

handles more than one type, reliable confirmation is required

before any work takes place.

The customer, therefore, wants identification to take place as

soon as the metal body is clamped into the lift at the reception

point. There are two variations of the chassis. Identifying them

confirms that the model corresponds to the operator's

production order.

Since the process involves the movement of large metal parts,

the sensor used for identification should be rugged enough to

withstand heavy impacts. The loading process is performed

manually by an operator, so movements and positions are

imprecise, while mechanical shocks to the sensor can be

expected. A long sensing distance is required.

The sensor is configured with an industry-standard PNP

normally-open interface, and connection to the turbine’s

control systems is via an integral M12 connector and PUR-

sheathed cable. This allows easy removal and replacement

during routine maintenance. The sensor is corrosion-resistant

and impervious to water ingress. Reliability has been excellent.

Contrinex inductive sensors deliver a cost-effective solution

that satisfies the customer’s requirements for a simple, fit-

and-forget system.

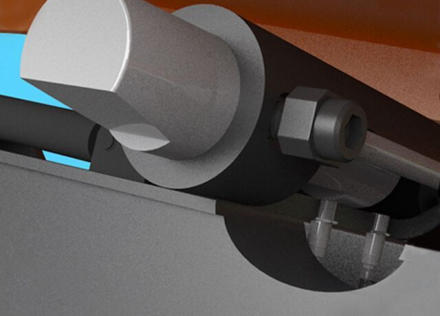

A range of multi-purpose off-road tractors allows the driver to

choose between two-wheel or four-wheel steering. When

selecting two-wheel steering using the front wheels only, the

rear axle is locked in the straight-ahead position. Before the

axle is locked, rugged inductive sensors from Contrinex detect

the straight-ahead position accurately and reliably, ensuring

precise alignment of the tractor’s steering geometry.

CUSTOMER APPLICATION

Modern multi-purpose off-road utility vehicles are

exceptionally versatile, offering four-wheel drive and both front

and rear-wheel steering. Reliable operation all year round, on

all types of terrain and in all weather conditions, is essential as

typical tasks include bulk-load transportation and agricultural

engineering.

Extreme conditions often demand increased manoeuvrability;

for maximum control, the driver can engage four-wheel

steering when required. When reverting to the default two-

wheel steering configuration, the rear axle must be locked in

the straight-ahead position to prevent misalignment of the

rear wheels.

A rugged, reliable and accurate sensor system is required to

detect the straight-ahead position of the rear axle before it is

locked. The sensor must withstand significant mechanical

shock and vibration and must also be impervious to water

ingress. Additionally, it should accommodate the extremes of

temperature experienced during all-year-round operation.

CUSTOMER VALUES

RELIABLE, REPEATABLE SENSING PERFORMANCE IN

DEMANDING OPERATING CONDITIONS

FIT-AND-FORGET OPERATION WITH MINIMAL MAINTENANCE

TECHNICALLY ELEGANT, COST-EFFECTIVE SOLUTION

REQUIRING MINIMAL RE-ENGINEERING

PRODUCT ADVANTAGES

2MM SENSING DISTANCE ELIMINATES THE POSSIBILITY OF

ACCIDENTAL DAMAGE TO THE SENSOR

RUGGED, ROBUST STAINLESS-STEEL SENSOR WITH INTEGRAL

M8 CONNECTOR

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY - FIT-AND-FORGET OPERATION

WITH MINIMAL MAINTENANCE

Configured with an industry-standard PNP normally-open

interface, the sensor features an integral M8 connector and

connects to the vehicle’s central controller via a flexible PVC-

sheathed cable. Adding the sensor requires minimal

modification to the vehicle’s control systems, and

maintenance is simple and speedy.

The sensor detects the straight-ahead position of the vehicle’s

rear axle repeatably and accurately, ensuring correct, reliable

engagement of two-wheel steering. Contrinex inductive

sensors provide the customer with a cost-effective fit-and-

forget solution to a challenging problem.

CUSTOMER SOLUTION

Inductive sensors from the Contrinex ‘Basic’ range are rugged,

reliable and accommodate the required extremes of

temperature; with an M8-sized sensor being ideal for this

application.

A V2A/AISI 303 stainless-steel body and vacuum-encapsulated

electronics, make it particularly suitable for the mechanically

demanding environment, and it is rated for operation at

temperatures between -25ºC (-13ºF) and 70ºC (158ºF).

A narrow flange is attached to each end of the vehicle’s

hydraulic power-steering rack. The sensor is mounted

immediately below one end of the rack and detects the

position of the flange as it passes over the sensing face. The

sensing distance of 2mm eliminates any possibility of

accidental collision with the flange.

CUSTOMER VALUES

SIMPLE SENSOR SYSTEM PROVIDING CONTACTLESS

OPERATION

ROBUST CONSTRUCTION WITHSTANDS CORROSION AND

WATER INGRESS

EXCEPTIONALLY RELIABLE, FIT-AND-FORGET OPERATION IN A

REMOTE, HARSH ENVIRONMENT

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, ONE-PIECE AISI 304 (V2A)

STAINLESS-STEEL BODY

STATE-OF-THE-ART ASIC TECHNOLOGY ENSURES

EXCEPTIONAL IN-SERVICE RELIABILITY

10 MM SENSING RANGE AVAILABLE IN PHYSICALLY SMALL

SENSOR

EXCELLENT RESISTANCE TO EXTREME OPERATING CONDITIONS

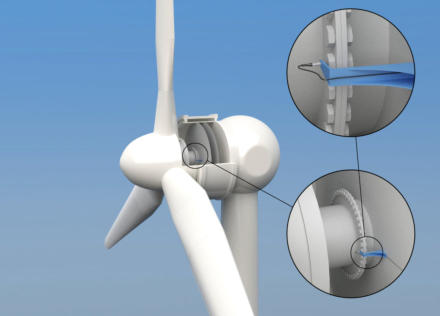

A single sensor is mounted in each turbine head, immediately

adjacent to the main mounting ring for the blade assembly. As

the blades rotate, so does the mounting ring, and the sensor

detects the presence of each mounting bolt as it passes the

sensing face. The angular spacing of the bolts is known.

Measuring the time that elapses between successive signals

thus allows the rotation velocity of the blades to be calculated.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

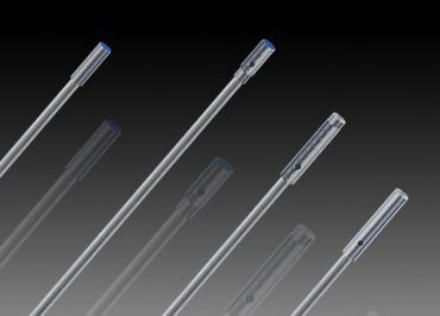

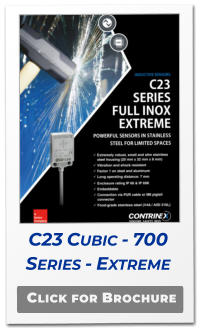

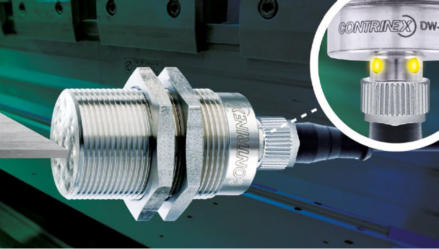

700 SERIES EXTREME ROBUST STAINLESS-STEEL INDUCTIVE SENSORS - ‘HAMMER HOME’ AN ADVANTAGE

PRODUCT ADVANTAGES

WORLD CLASS PERFORMANCE IN EXTREME ENVIRONMENTS

CORROSION-RESISTANT, AISI 304 V2A STAINLESS-STEEL

BODY

EXTREMELY ROBUST ONE-PIECE, STAINLESS-STEEL HOUSING -

IMPACT AND ABRASION RESISTANT - IP68/ IP69K RATED

FACTOR 1 WITH BOTH FERROUS AND NON-FERROUS

MATERIALS INCLUDING ALUMINIUM & BRASS FOR EXTENDED

SENSING

CAN OPERATE IN CLOSE PROXIMITY WITHOUT INTERFERENCE

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Exceptional performance combined with unique robustness make Contrinex’s Full stainless-steel EXTREME inductive sensors the

solution where reliability is valued. Thanks to their housing being machined from a single piece of V2A/AISI 303 stainless-steel and a

hermetically sealed cable entry, Extreme sensors are corrosion-resistant, impervious to oil, and pressure-resistant to 100 bar.

Rugged, reliable and highly accurate, the EXTREME range is at home in the most challenging applications.

Developed to withstand the harshest industrial operating conditions, Extreme sensors are rated to IP68 and IP69K, delivering fit-

and-forget performance with minimal downtime. With operating distances up to 40 mm, the Extreme range senses both ferrous

and non-ferrous materials with Factor 1 performance, and is available in sizes from M8 to M30 and C23.

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme range are ideal for this application. Highly

reliable and rated to IP68 or IP69K, these units provide a cost-

effective alternative to tradition rotary-encoder technology.

A one-piece M18-diameter AISI 304 (V2A) stainless-steel body

and vacuum-encapsulated electronics make this device

particularly suitable for the hostile environment, and the

sensing distance of 10 mm allows fully contactless operation.

Modern wind turbines operate continuously in remote, highly

demanding environments. Exceptional reliability is essential as

opportunities for maintenance are limited. Turbine rotation

velocity is a key operating parameter and manufacturers

require robust sensor systems that provide accurate

measurement in real-time. Contrinex’s rugged inductive

sensors provide presence-sensing systems which withstand

harsh exposed conditions, both onshore and offshore, while

delivering the required accuracy and reliability.

CUSTOMER APPLICATION

A manufacturer of wind turbines provides engineering

support for systems installed around the globe. The company’s

field-service capability is backed by 24-hour remote data

monitoring, allowing early detection of potential problems.

Given the remote location of most wind farms, monitoring

systems must be exceptionally reliable, as site attendance is

infrequent.

Turbine rotation velocity is a key operating parameter, and the

company requires robust sensor systems that provide accurate

data in real-time. Traditional rotary-encoder technology is

unsuitable as sensors do not withstand prolonged exposure to

outdoor, often salt-laden, environments. In addition, turbine

rotation speeds are relatively low, typically requiring more

complex mechanical encoders.

The company requires a simple, contactless system that

provides fit-and-forget operation with extended maintenance

intervals. Sensors must be mechanically robust and must

withstand prolonged exposure to harsh outdoor conditions

including seawater. An industry-standard interface is highly

desirable to avoid the need for specialised control systems.

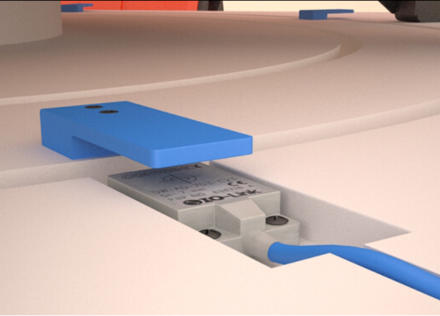

Conveyors deliver a continuous stream of parts to the rotary

indexing table, which transports them in sequence to each

assembly station. As the table rotates, sensors located at

precise intervals around its periphery detect its exact angular

position, bringing it to a halt once parts are correctly

positioned for the next operation.

At each assembly station, automated pick-and-place

equipment add components to the assembly. Dedicated

transport mechanisms – including vacuum lifters,

electromagnetic clamps and mechanical grippers – insert

items swiftly and accurately in their designated positions.

Embeddable inductive sensors play a key role in confirming

the secure closure of custom-designed grippers before fragile,

high-value parts are lifted.

Manufactured in V4A/ AISI 316L stainless steel and rated to

IP68/ IP69K, these small inductive sensors can be fully

embedded into a steel surface such as part of the rotary table

or an assembly jig or bench, further reducing the potential for

mechanical damage.

On completion of the final assembly stage, finished PCBs are

discharged to a linear conveyor system. They travel to

subsequent processing stages, including testing and packing.

C23 Full stainless steel sensors mounted directly above these

conveyors, detect each unit as it passes below. This check not

only confirms the presence of the assembled item at the

expected height above the conveyor but also measures

throughput by activating a counting circuit in the customer’s

control system.

Continuous operation is the norm in automated assembly

plants. However, minor adjustments or tool changes may be

required from time to time. In non-safety-critical areas, access

hatches allow maintenance technicians to carry out these

tasks without needing to interrupt production across an entire

plant. Multiple sensors, mounted at intervals around the

periphery of a hatch, ensure that appropriate warning signals

are activated whenever the opening is not fully secured.

The Contrinex C23 series of Full stainless-steel inductive

sensors have the capability of communicating remotely with a

plant-wide control system, thanks to the implementation of

the IO-Link protocol. In a typical automated plant, each

assembly line runs continuously throughout the day, with

remote diagnostics eliminating the need for manual

intervention in almost every situation.

Designed to simplify integration, IO-Link sensors are

compatible with all IO-Link master versions, allowing set-up

and diagnostics to be conducted centrally. Interrogating a

device returns its manufacturer ID and product ID, allowing

systems integrators to determine remotely that the right

sensor is in the correct location. Contrinex C23 inductive

sensors additionally feature an on-demand self-test function

that confirms full capability at all times.

For the C23 inductive series, alternating between normally

open and normally closed functionality via remote output-

mode configuration is a standard feature of the IO-Link

protocol. Systems designers also can modify the output signal.

Delaying the switching pulse accommodates any travel time

between a sensor and its corresponding actuation point, while

stretching the pulse ensures that slave devices with lengthy

response times trigger reliably, even at high throughput rates.

Finally, each sensor provides an output-status check derived

from its factory calibration data. If the output signal from a

sensor falls outside a range that corresponds to a sensing

distance between 80% and 100% of its nominal value, an alarm

flag is triggered, highlighting the need for investigation. For

plant managers under pressure, peace-of-mind is a valuable

benefit.

The no-cost option of the industry-standard IO-Link protocol

ensures that best-in-class performance is coupled with

ultimate ease of use in even the most demanding

circumstances.

CUSTOMER VALUES

ELIMINATION OF HUMAN ERROR PREVENTS TRUCK BEING

DRIVEN IN AN UNSAFE CONDITION.

HIGHLY RELIABLE SENSING PERFORMANCE IN HIGHLY

DEMANDING CONDITIONS

CORROSION-RESISTANT SENSORS WITHSTAND WATER, ICE,

MUD AND SALT

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY

SERIOUS PROBLEM

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

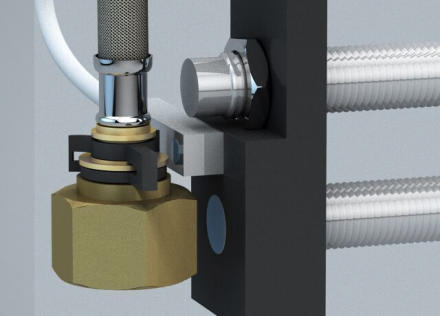

Stainless-steel-braided hydraulic hoses for water heaters

undergo over-pressure testing at the final stage of

manufacture. Before pressure is applied, a multi-sensor system

checks each hose assembly to ensure that the correct

mechanical parts have been fitted. Applying high pressure to

an incomplete assembly could result in catastrophic failure,

damaging test equipment and putting operators at risk of

injury.

CUSTOMER APPLICATION

A manufacturer of stainless-steel-braided high-pressure hoses

for water heaters carries out mandatory over-pressure testing

on every hose assembly. If either of the mechanical unions

fitted to the ends of each hose is incorrectly assembled, it will

leak under pressure.

Occasionally, a component is omitted entirely, making a hose

liable to fail catastrophically under high pressure. To avoid

damaging test equipment and endangering personnel, a

sensor system must confirm the presence of three critical

parts on each union before testing commences.

Each extra test extends the process cycle time. The customer

requires a single test fixture capable of carrying out three

presence checks concurrently, minimizing the additional cost.

The three critical parts, made from stainless steel, carbon steel

and brass, respectively, are positioned in close proximity when

assembled. Access is limited; the three sensors must be small,

yet sense these materials reliably at distances up to 6mm

(0.25in)

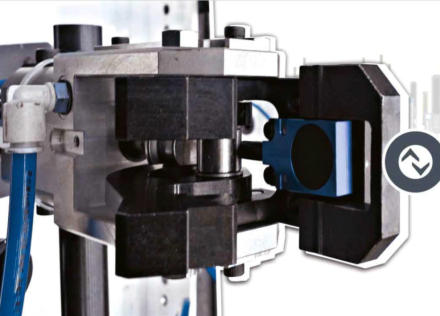

Finally, to ensure reliable detection of the stainless-steel collar,

an M8-diameter sensor from the Extreme range (Full stainless-

steel family) was chosen. Its one-piece AISI 303 (V2A) stainless-

steel construction is combined with an extended operating

distance of 6mm.

CUSTOMER VALUES

RELIABLE, REPEATABLE DETECTION OF THREE DISCRETE

PARTS IN A SINGLE OPERATION

ELIMINATION OF UNSAFE OCCURRENCES DUE TO FAULTY HOSE

ASSEMBLIES

HIGHLY COST-EFFECTIVE SOLUTION TO A PREVIOUSLY

INSOLUBLE PROBLEM.

PRODUCT ADVANTAGES

EXCEPTIONAL SENSING DISTANCES IN SMALL SENSOR

ENVELOPES

CORRECTION FACTOR OF 1.0 FOR BRASS ALLOWS EXTENDED

SENSING DISTANCE

SENSORS OPERATE IN CLOSE PROXIMITY WITHOUT

INTERFERENCE

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Customer Solution

By mounting three separate M8- and C5-sized Contrinex

inductive sensors in a single fixture, all the demands of this

application can be met in full. Each sensor is chosen for its

combination of size, sensing distance and reliable detection of

one of the three different materials.

To detect the brass union nut, an M8-diameter sensor from

the Basic range (Extra Distance family) with a 4mm sensing

distance is an excellent choice. Fully embeddable with

chrome-plated nickel-silver bodies and PBTP sensing faces,

this sensor has a correction factor of 1.0 for brass,

outperforming competitors.

For detecting the steel spring, a 5mm-square-section sensor

from the Miniature range (Classics family) is an ideal option.

Embedding the sensor makes optimal use of its 1.5mm

sensing distance, and its chrome-plated brass body is well-

suited to the environment.

Each sensor is configured with an industry-standard PNP

normally-open interface and features a hermetically sealed

cable entry. All three are connected to the customer’s control

equipment via PUR-sheathed cables. Delivering the required

detection capabilities and sensing distances in small-bodied

sensors enables Contrinex to solve a previously insoluble

problem.

Hook loader trucks utilise a hydraulic system for loading and

unloading a demountable container. Once the container is

correctly positioned on the vehicle’s load bed, interlocks

engage with its base, securing it in position. Contrinex’s

rugged sensor systems detect full engagement of the

interlocks, ensuring the truck is safely loaded prior to driving

away. Therefore, the sensors must be mechanically robust and

able to withstand harsh outdoor conditions.

CUSTOMER APPLICATION

A specialist vehicle builder manufactures hydraulic hook-lift

systems for commercial trucks. A hook loader truck employs a

series of hydraulic rams to hook, lift and pull a demountable

container onto the vehicle’s load bed; a full container may

weigh up to 30 tons.

Hook loader trucks operate all year round, often in harsh

environments such as demolition and construction sites.

Hook-lift systems are typically semi-automated. The driver

positions the truck, engages the hook with the container and

initiates the lifting sequence. Once the container is pulled onto

the load bed, two interlock mechanisms, mounted on the

truck chassis, actuate and engage with the container body.

Once the interlocks are fully engaged, the container is secure

and the truck may be driven safely.

A highly reliable sensor system must detect the position of the

interlocks, ensuring that they are fully engaged before the

truck drives away. Sensors must be robust and must withstand

water, mud, dirt and ice. They may also be subject to

mechanical shock and vibration.

CUSTOMER VALUES

EFFICIENT, FAULT-FREE ASSEMBLY.

NO SENSOR-RELATED DOWNTIME.

DIGITAL COMMUNICATION WITHOUT NEEDING SPECIAL

CABLING.

OUTSTANDING PROCESS MONITORING & CONTROL

CAPABILITIES.

FAST, EASY SET-UP AND RECONFIGURATION.

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY ON C23 AND AVAILABLE AS AN

OPTION ON CYCLINDRICAL SENSORS.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Fault-free assembly is ensured, downtime minimised and

assembly speed increased by using automated facilities for

high volume assembly. Rugged inductive sensors detect the

presence and position of equipment or components at each

stage to ensure that parts are correctly aligned and ready for

the next operation. The sensors must be accurate and

responsive. In addition, an IO-Link interface offers the

advantages of digital communication without the need for

special cabling.

CUSTOMER APPLICATION

Highly reliable automation and machine-control systems are

used to eliminate assembly faults and improve efficiency in an

assembly operation. Whilst the repetitive assembly tasks are

well-suited to being done by robots, these robots can be too

slow at picking and placing the assembled parts and therefore

a rotary indexing table is used to move the assemblies

between the robots.

The rotary indexing table speeds up the transfer of PCBs

between assembly robots and also on and off conveyors,

increasing the production throughput and reducing the

number of assembly robots required – Sensors are used to

automate these processes and these sensors must be able to

operate continuously at high speed, performing tasks

including: presence detection to initiate the cassette-change

cycle in a stack feeder; position control for a rotary indexing

table; pick-and-place gripper control; and presence monitoring

on a conveyor system.

Customer Solution

Stack-feeders deliver base plates, electrical printed circuit

boards and other planar components to the assembly lines. In

each stack-feeder, a vertical cassette holds as many as 50

individual parts and a single inductive sensor monitors the

status of each cassette. Once the final part is discharged from

the stack, the cassette moves to its end position, triggering the

sensor and initiating the cassette-change cycle.

Contrinex C23 embeddable inductive sensors, featuring a one-

piece stainless-steel housing, are both robust and highly

reliable. A 7mm sensing distance allows ample operating

clearance, minimizing the risk of mechanical collision. Their

implementation into the assembly equipment is made easier

by the choice of industry-standard PNP or NPN outputs with

either a PUR cable or an M8 pigtail connector. Additionally, IO-

Link, a standardised point-to-point serial connection protocol

for sensors and actuators, is provided at no additional cost,

offering the advantages of digital communication without the

need for special cabling, making them ideal for Industry 4

applications.

Designed for demanding applications, Contrinex’s rugged C23

inductive sensors offer best-in-class switching frequency of

180Hz and exceptional robustness including impact and

abrasion resistance, making them a versatile, cost-effective

and highly reliable solution. These uniquely robust sensors are

typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly

THE INNOVATIVE INDUCTIVE SENSOR FAMILY, WHICH IS SO IMPACT AND ABRASION RESISTANT THAT

YOU CAN USE IT TO HAMMER IN NAILS - IMAGINE HOW THEY CAN REDUCE MACHINE DOWN-TIME.

700 SERIES - ‘EXTREME’ ROBUST

STAINLESS-STEEL INDUCTIVE SENSORS

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme 700 Series are designed for demanding or

even exceptionally demanding environments, making them

ideal for this application. Highly reliable and IP68 / IP69K rated,

these embeddable units feature one-piece V2A (AISI 304)

stainless-steel construction with vacuum-encapsulated

electronics, making them well suited to the hostile operating

conditions.

During operation, a double-ended ram drives a pair of

interlock bolts into position. On either side of the truck, two

M18-diameter sensors are mounted in the wall of each bolt

housing; one detects the bolt as it reaches the fully engaged

position; the other detects it in the fully retracted position. A

second ram drives a rotating lock mechanism to engage with

the vehicle chassis; a further two sensors detect the position of

a cam on the locking shaft as it rotates.

Each sensor is configured with an industry-standard PNP

normally-open interface, and connection to the truck’s

hydraulic control system is via an integral M12 connector and

PUR-sheathed cable. This allows easy removal and

replacement during routine maintenance.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS, WE WILL WORK TO HELP YOU

SOLVE YOUR APPLICATIONS, IMPROVE MACHINE PERFORMANCE & RELIABILITY AND REDUCE COSTS

USING CONTRINEX’S EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS

Rugged sensor construction ensures excellent resistance to

shock and vibration and a sensing distance of up to 10mm

eliminates any risk of accidental collision with moving parts.

These devices are corrosion-resistant and impervious to water

ingress, mud, ice and salt. Reliability has been excellent.

Contrinex inductive sensors deliver a cost-effective solution

that satisfies the customer’s requirements for a simple, fit-

and-forget system.

CUSTOMER VALUES

SAFE, RELIABLE PERFORMANCE IN A DEMANDING OUTDOOR

ENVIRONMENT

NO LIKELIHOOD OF ACCIDENTAL DAMAGE ARISING IN

OPERATION

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

CORROSION-RESISTANT STAINLESS-STEEL SENSOR RATED TO

IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

CUSTOMER SOLUTION

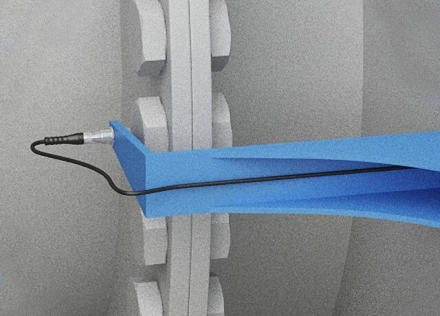

Contrinex inductive sensors are robust, reliable and offer

extended sensing distances; the Full Inox Extreme range is

ideal for this application. A one-piece M30-diameter stainless-

steel body and vacuum-encapsulated electronics make this

device particularly suitable for the mechanically demanding

environment, and the sensing distance of 20mm eliminates

any possibility of accidental collision in operation.

A metal bracket is mounted externally on the actuating

mechanism for the upper forks; the embeddable sensor is

mounted immediately adjacent to one of the forks and detects

the position of the actuating arm as it drives the fork into the

vertical position. The AISI 303/V2A stainless-steel housing and

sensing face are corrosion-resistant and impervious to water

ingress; the sensor is IP68- and IP69K-rated.

Configured with an industry-standard PNP normally-open

interface, the Contrinex M30 Extreme sensor connects to the

forklift’s lower-fork tilt-control systems via a flexible PUR-

sheathed cable. A sealed cable entry ensures fit-and-forget

capability during extended periods of operation in an outdoor

environment.

The Full Inox inductive sensor detects the vertical position of

the forklift’s upper forks effectively and repeatably, ensuring

safe, reliable operation of the unloading system. Contrinex

inductive sensors deliver a cost-effective solution that satisfies

the customer’s requirements for extreme robustness and

extended sensing distance.

A container manufacturer uses a modified forklift, fitted with

two sets of forks, for unloading bulk cargo. The lower forks

support the container while the upper forks control the lid.

When unloading, the lid opens and the lower forks rotate,

tipping out the contents. A robust inductive sensor senses the

position of the lid, ensuring it opens fully before emptying.

CUSTOMER APPLICATION

Containers are often used when transporting bulk cargo,

including wood chip and biomass, by rail. A manufacturer of

bulk-cargo containers has developed an innovative unloading

system that uses only a modified forklift, eliminating the need

for specialist handling equipment.

The forklift has two pairs of lifting forks. The main forks,

mounted conventionally, support the weight of the container

as it is unloaded from a freight wagon; a second pair, mounted

vertically above the lower pair, opens and closes the lid of the

container. During opening, the upper forks lift the lid a short

distance before tilting it vertically, leaving the top of the

container completely unobstructed.

The lower forks then rotate about a horizontal axis, tilting the

container end-over-end and tipping the contents out. A robust

and reliable sensor system is required to detect the vertical

position of the lid before rotation begins. An extended sensing

distance is essential to eliminate the possibility of mechanical

damage.

CUSTOMER VALUES

HIGHLY COST EFFECTIVE SOLUTION - SUBSTANTIALLY LOWER

COST THAN OTHER DOUBLE-SHEET DETECTION SOLUTIONS

SIMPLE SETUP AND USE

ELIMINATES MACHINE JAMS, BREAKAGE OF TOOLING AND SO

ELIMINATES PRODUCTION DOWNTIME

CORROSION-RESISTANT SENSORS WITHSTAND CLEANING

PRODUCT ADVANTAGES

UNIQUE TECHNOLOGY DEFIES LIMITS OF TRADITIONAL

INDUCTIVE SENSOR TECHNOLOGY

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K STAINLESS-STEEL RATED HOUSING

CORROSION-RESISTANT, V2A/ AISI 304 STAINLESS-STEEL,

FOOD-COMPATIBLE BODY

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

A manufacturer of metal cans needs to ensure that the press

that applies and crimps the bottom onto the can body is fed

with only one bottom. Therefore a fast, non-contact and robust

checking mechanism is required.

CUSTOMER APPLICATION

A conveyor with a stainless-steel glide plate backed by a

permanent magnet ensures that the can bottoms travel

perfectly flat on the belt which transports them to the

assembly stage. If double-bottoms are fed into the assembly

stage, damage can be done to the press, tools can be broken,

and even the press becoming jammed will cause production

downtime.

To check that only one bottom is being fed to the assembly

stage whilst they are attached magnetically to the fast-moving

belt, requires a non-contact sensing solution. The thin gauge

of steel used to produce the can bottoms (~0.33 mm thick) is

too small for the customer’s normal automatic double-sheet

detector to work reliably.

CUSTOMER SOLUTION

Contrinex’s Extreme 700 Series sensors provide a robust and

simple, cost effective solution. They utilise their Condet®

technology to detect the mass of a target by inducing a

voltage in it, whereas a traditional inductive sensor would

induce the voltage only in the target’s surface.

The stainless-steel bodied sensor (DW-Ax-70X-M12) is mounted

approximately 4 – 5 mm above the dome of a can bottom. On

its own, the 0.33mm thick steel doom presents insufficient

mass to switch the sensor at this distance, however the

presence of a second bottom piece increases target mass

sufficiently to switch the sensor.

The inductive sensor triggers a rejection shoot whenever two

bottoms are detected as being stacked together and so

provide a robust and reliable system to protect the assembly

press.

CUSTOMER VALUES

COST SAVING DUE TO REDUCED DOWNTIME CAUSED BY

SENSOR DAMAGE AND REPLACEMENT

SAFE, RELIABLE PERFORMANCE IN A DEMANDING

ENVIRONMENT FOR INCREASED PROCESS SECURITY

COST-EFFECTIVE SOLUTION, MAINTENANCE FREE

PRODUCT ADVANTAGES

MECHANICALLY RUGGED, CORROSION-RESISTANT STAINLESS-

STEEL SENSOR RATED TO IP68 AND IP69K

COST-EFFECTIVE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY

BEST-IN-CLASS 20MM SENSING DISTANCE IN M30-DIAMETER

HOUSING

FACTOR 1: IDENTICAL OPERATING DISTANCES ON STEEL AND

ALUMINIUM

CUSTOMER SOLUTION

Contrinex’s DW-AS-703-M30-002 inductive sensor is ideal for

this application. The 700 Series sensor’s long sensing distances

(20 mm in this case) detect equally well on both steel and

aluminium, which is often called ‘factor 1’ sensing.

The sensor selected detects the absence or presence of a

model-dependent metal part that identifies the model. If the

wrong model is identified, an alarm is generated to warn the

operator.

The Condet detection technology protects it from

environmental and material influences. and its all-metal, AISI

303/V2A stainless-steel housing and sensing face protect it

from corrosion and water ingress.

The 700 series of inductive sensors are much more resistant to

mechanical stresses than conventional sensors which makes

them ideal for this application since the process involves the

movement of large metal parts.

The sensor used for identification should be rugged enough to

withstand heavy impacts as the loading process is performed

manually by an operator, so movements and positions are

imprecise, while mechanical shocks to the sensor can be

expected and a long sensing distance is required.

An automotive manufacturer uses simple, low-cost inductive

sensors to identify which style of chassis it receives in the body

shop, to define what further processing should take place.

CUSTOMER APPLICATION

The customer manufactures a wide range of vehicles and so as

each body arrives at the body shop, operators use pulleys and

clamps to lift it onto the line. Since the same body shop

handles more than one type, reliable confirmation is required

before any work takes place.

The customer, therefore, wants identification to take place as

soon as the metal body is clamped into the lift at the reception

point. There are two variations of the chassis. Identifying them

confirms that the model corresponds to the operator's

production order.

Since the process involves the movement of large metal parts,

the sensor used for identification should be rugged enough to

withstand heavy impacts. The loading process is performed

manually by an operator, so movements and positions are

imprecise, while mechanical shocks to the sensor can be

expected. A long sensing distance is required.

CLICK ON AN IMAGE TO VIEW THE BROCHURE OR

A VIDEO, READ APPLICATION EXAMPLES BELOW,

CLICK HERE TO VIEW THIS SENSOR ON

CONTRINEX’S WEBSITE, OR CALL US TO HELP GUIDE

YOU THROUGH SELECTION, ANSWER QUESTIONS,

OR TO HELP YOU #MAKESENSEOFSENSORS:

700 SERIES - ‘EXTREME’

ROBUST STAINLESS-STEEL

INDUCTIVE SENSORS

THE INNOVATIVE INDUCTIVE SENSOR FAMILY, WHICH IS

SO IMPACT AND ABRASION RESISTANT THAT YOU CAN

USE IT TO HAMMER IN NAILS - IMAGINE HOW THEY CAN

REDUCE MACHINE DOWN-TIME.

Fault-free assembly is ensured, downtime minimised and

assembly speed increased by using automated facilities for

high volume assembly. Rugged inductive sensors detect the

presence and position of equipment or components at each

stage to ensure that parts are correctly aligned and ready for

the next operation. The sensors must be accurate and

responsive. In addition, an IO-Link interface offers the

advantages of digital communication without the need for

special cabling.

CUSTOMER APPLICATION

Highly reliable automation and machine-control systems are

used to eliminate assembly faults and improve efficiency in an

assembly operation. Whilst the repetitive assembly tasks are

well-suited to being done by robots, these robots can be too

slow at picking and placing the assembled parts and therefore

a rotary indexing table is used to move the assemblies

between the robots.

The rotary indexing table speeds up the transfer of PCBs

between assembly robots and also on and off conveyors,

increasing the production throughput and reducing the

number of assembly robots required – Sensors are used to

automate these processes and these sensors must be able to

operate continuously at high speed, performing tasks

including: presence detection to initiate the cassette-change

cycle in a stack feeder; position control for a rotary indexing

table; pick-and-place gripper control; and presence monitoring

on a conveyor system.

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme 700 Series are designed for demanding or

even exceptionally demanding environments, making them

ideal for this application. Highly reliable and IP68 / IP69K rated,

these embeddable units feature one-piece V2A (AISI 304)

stainless-steel construction with vacuum-encapsulated

electronics, making them well suited to the hostile operating

conditions.

During operation, a double-ended ram drives a pair of

interlock bolts into position. On either side of the truck, two

M18-diameter sensors are mounted in the wall of each bolt

housing; one detects the bolt as it reaches the fully engaged

position; the other detects it in the fully retracted position. A

second ram drives a rotating lock mechanism to engage with

the vehicle chassis; a further two sensors detect the position of

a cam on the locking shaft as it rotates.

Each sensor is configured with an industry-standard PNP

normally-open interface, and connection to the truck’s

hydraulic control system is via an integral M12 connector and

PUR-sheathed cable. This allows easy removal and

replacement during routine maintenance.

Hook loader trucks utilise a hydraulic system for loading and

unloading a demountable container. Once the container is

correctly positioned on the vehicle’s load bed, interlocks

engage with its base, securing it in position. Contrinex’s

rugged sensor systems detect full engagement of the

interlocks, ensuring the truck is safely loaded prior to driving

away. Therefore, the sensors must be mechanically robust and

able to withstand harsh outdoor conditions.

CUSTOMER APPLICATION

A specialist vehicle builder manufactures hydraulic hook-lift

systems for commercial trucks. A hook loader truck employs a

series of hydraulic rams to hook, lift and pull a demountable

container onto the vehicle’s load bed; a full container may

weigh up to 30 tons.

Hook loader trucks operate all year round, often in harsh

environments such as demolition and construction sites.

Hook-lift systems are typically semi-automated. The driver

positions the truck, engages the hook with the container and

initiates the lifting sequence. Once the container is pulled onto

the load bed, two interlock mechanisms, mounted on the

truck chassis, actuate and engage with the container body.

Once the interlocks are fully engaged, the container is secure

and the truck may be driven safely.

A highly reliable sensor system must detect the position of the

interlocks, ensuring that they are fully engaged before the

truck drives away. Sensors must be robust and must withstand

water, mud, dirt and ice. They may also be subject to

mechanical shock and vibration.

CUSTOMER VALUES

EFFICIENT, FAULT-FREE ASSEMBLY.

NO SENSOR-RELATED DOWNTIME.

DIGITAL COMMUNICATION WITHOUT NEEDING SPECIAL

CABLING.

OUTSTANDING PROCESS MONITORING & CONTROL

CAPABILITIES.

FAST, EASY SET-UP AND RECONFIGURATION.

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Customer Solution

Stack-feeders deliver base plates, electrical printed circuit

boards and other planar components to the assembly lines. In

each stack-feeder, a vertical cassette holds as many as 50

individual parts and a single inductive sensor monitors the

status of each cassette. Once the final part is discharged from

the stack, the cassette moves to its end position, triggering the

sensor and initiating the cassette-change cycle.

Contrinex C23 embeddable inductive sensors, featuring a one-

piece stainless-steel housing, are both robust and highly

reliable. A 7mm sensing distance allows ample operating

clearance, minimizing the risk of mechanical collision. Their

implementation into the assembly equipment is made easier

by the choice of industry-standard PNP or NPN outputs with

either a PUR cable or an M8 pigtail connector. Additionally, IO-

Link, a standardised point-to-point serial connection protocol

for sensors and actuators, is provided at no additional cost,

offering the advantages of digital communication without the

need for special cabling, making them ideal for Industry 4

applications.

Designed for demanding applications, Contrinex’s rugged C23

inductive sensors offer best-in-class switching frequency of

180Hz and exceptional robustness including impact and

abrasion resistance, making them a versatile, cost-effective

and highly reliable solution. These uniquely robust sensors are

typically demonstrated by Contrinex as being able to

repeatedly being used to hammer in nails. Even when their

front face is dented, the sensor continues to operate correctly

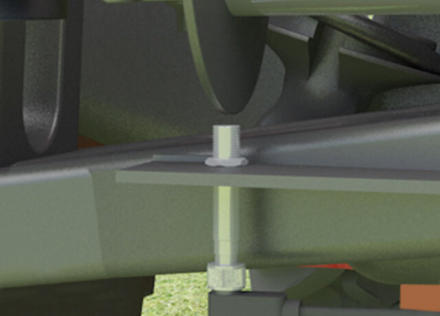

A range of multi-purpose off-road tractors allows the driver to

choose between two-wheel or four-wheel steering. When

selecting two-wheel steering using the front wheels only, the

rear axle is locked in the straight-ahead position. Before the

axle is locked, rugged inductive sensors from Contrinex detect

the straight-ahead position accurately and reliably, ensuring

precise alignment of the tractor’s steering geometry.

CUSTOMER APPLICATION

Modern multi-purpose off-road utility vehicles are

exceptionally versatile, offering four-wheel drive and both front

and rear-wheel steering. Reliable operation all year round, on

all types of terrain and in all weather conditions, is essential as

typical tasks include bulk-load transportation and agricultural

engineering.

Extreme conditions often demand increased manoeuvrability;

for maximum control, the driver can engage four-wheel

steering when required. When reverting to the default two-

wheel steering configuration, the rear axle must be locked in

the straight-ahead position to prevent misalignment of the

rear wheels.

A rugged, reliable and accurate sensor system is required to

detect the straight-ahead position of the rear axle before it is

locked. The sensor must withstand significant mechanical

shock and vibration and must also be impervious to water

ingress. Additionally, it should accommodate the extremes of

temperature experienced during all-year-round operation.

CUSTOMER VALUES

RELIABLE, REPEATABLE SENSING PERFORMANCE IN

DEMANDING OPERATING CONDITIONS

FIT-AND-FORGET OPERATION WITH MINIMAL MAINTENANCE

TECHNICALLY ELEGANT, COST-EFFECTIVE SOLUTION

REQUIRING MINIMAL RE-ENGINEERING

PRODUCT ADVANTAGES

2MM SENSING DISTANCE ELIMINATES THE POSSIBILITY OF

ACCIDENTAL DAMAGE TO THE SENSOR

RUGGED, ROBUST STAINLESS-STEEL SENSOR WITH INTEGRAL

M8 CONNECTOR

AFFORDABLE HIGH-PERFORMANCE SENSOR WITH

EXCEPTIONAL RELIABILITY - FIT-AND-FORGET OPERATION

WITH MINIMAL MAINTENANCE

Configured with an industry-standard PNP normally-open

interface, the sensor features an integral M8 connector and

connects to the vehicle’s central controller via a flexible PVC-

sheathed cable. Adding the sensor requires minimal

modification to the vehicle’s control systems, and

maintenance is simple and speedy.

The sensor detects the straight-ahead position of the vehicle’s

rear axle repeatably and accurately, ensuring correct, reliable

engagement of two-wheel steering. Contrinex inductive

sensors provide the customer with a cost-effective fit-and-

forget solution to a challenging problem.

CUSTOMER SOLUTION

Inductive sensors from the Contrinex ‘Basic’ range are rugged,

reliable and accommodate the required extremes of

temperature; with an M8-sized sensor being ideal for this

application.

A V2A/AISI 303 stainless-steel body and vacuum-encapsulated

electronics, make it particularly suitable for the mechanically

demanding environment, and it is rated for operation at

temperatures between -25ºC (-13ºF) and 70ºC (158ºF).

A narrow flange is attached to each end of the vehicle’s

hydraulic power-steering rack. The sensor is mounted

immediately below one end of the rack and detects the

position of the flange as it passes over the sensing face. The

sensing distance of 2mm eliminates any possibility of

accidental collision with the flange.

Conveyors deliver a continuous stream of parts to the rotary

indexing table, which transports them in sequence to each

assembly station. As the table rotates, sensors located at

precise intervals around its periphery detect its exact angular

position, bringing it to a halt once parts are correctly

positioned for the next operation.

At each assembly station, automated pick-and-place

equipment add components to the assembly. Dedicated

transport mechanisms – including vacuum lifters,

electromagnetic clamps and mechanical grippers – insert

items swiftly and accurately in their designated positions.

Embeddable inductive sensors play a key role in confirming

the secure closure of custom-designed grippers before fragile,

high-value parts are lifted.

Manufactured in V4A/ AISI 316L stainless steel and rated to

IP68/ IP69K, these small inductive sensors can be fully

embedded into a steel surface such as part of the rotary table

or an assembly jig or bench, further reducing the potential for

mechanical damage.

On completion of the final assembly stage, finished PCBs are

discharged to a linear conveyor system. They travel to

subsequent processing stages, including testing and packing.

C23 Full stainless steel sensors mounted directly above these

conveyors, detect each unit as it passes below. This check not

only confirms the presence of the assembled item at the

expected height above the conveyor but also measures

throughput by activating a counting circuit in the customer’s

control system.

Continuous operation is the norm in automated assembly

plants. However, minor adjustments or tool changes may be

required from time to time. In non-safety-critical areas, access

hatches allow maintenance technicians to carry out these

tasks without needing to interrupt production across an entire

plant. Multiple sensors, mounted at intervals around the

periphery of a hatch, ensure that appropriate warning signals

are activated whenever the opening is not fully secured.

The Contrinex C23 series of Full stainless-steel inductive

sensors have the capability of communicating remotely with a

plant-wide control system, thanks to the implementation of

the IO-Link protocol. In a typical automated plant, each

assembly line runs continuously throughout the day, with

remote diagnostics eliminating the need for manual

intervention in almost every situation.

Designed to simplify integration, IO-Link sensors are

compatible with all IO-Link master versions, allowing set-up

and diagnostics to be conducted centrally. Interrogating a

device returns its manufacturer ID and product ID, allowing

systems integrators to determine remotely that the right

sensor is in the correct location. Contrinex C23 inductive

sensors additionally feature an on-demand self-test function

that confirms full capability at all times.

For the C23 inductive series, alternating between normally

open and normally closed functionality via remote output-

mode configuration is a standard feature of the IO-Link

protocol. Systems designers also can modify the output signal.

Delaying the switching pulse accommodates any travel time

between a sensor and its corresponding actuation point, while

stretching the pulse ensures that slave devices with lengthy

response times trigger reliably, even at high throughput rates.

Finally, each sensor provides an output-status check derived

from its factory calibration data. If the output signal from a

sensor falls outside a range that corresponds to a sensing

distance between 80% and 100% of its nominal value, an alarm

flag is triggered, highlighting the need for investigation. For

plant managers under pressure, peace-of-mind is a valuable

benefit.

The no-cost option of the industry-standard IO-Link protocol

ensures that best-in-class performance is coupled with

ultimate ease of use in even the most demanding

circumstances.

CUSTOMER VALUES

ELIMINATION OF HUMAN ERROR PREVENTS TRUCK BEING

DRIVEN IN AN UNSAFE CONDITION.

HIGHLY RELIABLE SENSING PERFORMANCE IN HIGHLY

DEMANDING CONDITIONS

CORROSION-RESISTANT SENSORS WITHSTAND WATER, ICE,

MUD AND SALT

HIGHLY COST-EFFECTIVE SOLUTION TO A POTENTIALLY

SERIOUS PROBLEM

PRODUCT ADVANTAGES

EXTREMELY ROBUST, IMPACT AND ABRASION RESISTANT IP68/

IP69K RATED HOUSING.

CORROSION-RESISTANT, V4A/ AISI 316L STAINLESS-STEEL,

FOOD-COMPATIBLE BODY.

LONG OPERATING DISTANCE OF 7MM IN A SMALL & SLIM

STAINLESS-STEEL 20X 32X 8MM HOUSING.

ROBUST, METAL-CASED INDUCTIVE PROXIMITY SENSORS

SUITABLE FOR EASY INTEGRATION

FACTOR 1 - CONSISTENT SENSING, IRRESPECTIVE OF WHETHER

THE TARGET IS STEEL OR ALUMINIUM.

RELIABLE, COMPACT VIBRATION-RESISTANT SENSORS

IO-LINK INTERFACE INCLUDED FOR FREE – IDEAL FOR

INDUSTRY 4

Stainless-steel-braided hydraulic hoses for water heaters

undergo over-pressure testing at the final stage of

manufacture. Before pressure is applied, a multi-sensor system

checks each hose assembly to ensure that the correct

mechanical parts have been fitted. Applying high pressure to

an incomplete assembly could result in catastrophic failure,

damaging test equipment and putting operators at risk of

injury.

CUSTOMER APPLICATION

A manufacturer of stainless-steel-braided high-pressure hoses

for water heaters carries out mandatory over-pressure testing

on every hose assembly. If either of the mechanical unions

fitted to the ends of each hose is incorrectly assembled, it will

leak under pressure.

Occasionally, a component is omitted entirely, making a hose

liable to fail catastrophically under high pressure. To avoid

damaging test equipment and endangering personnel, a

sensor system must confirm the presence of three critical

parts on each union before testing commences.

Each extra test extends the process cycle time. The customer

requires a single test fixture capable of carrying out three

presence checks concurrently, minimizing the additional cost.

The three critical parts, made from stainless steel, carbon steel

and brass, respectively, are positioned in close proximity when

assembled. Access is limited; the three sensors must be small,

yet sense these materials reliably at distances up to 6mm

(0.25in)

Finally, to ensure reliable detection of the stainless-steel collar,

an M8-diameter sensor from the Extreme range (Full stainless-

steel family) was chosen. Its one-piece AISI 303 (V2A) stainless-

steel construction is combined with an extended operating

distance of 6mm.

CUSTOMER VALUES

Reliable, repeatable detection of three discrete parts

in a single operation

Elimination of unsafe occurrences due to faulty hose

assemblies

Highly cost-effective solution to a previously

insoluble problem.

PRODUCT ADVANTAGES

Exceptional sensing distances in small sensor

envelopes

Correction factor of 1.0 for brass allows extended

sensing distance

Sensors operate in close proximity without

interference

Reliable, compact vibration-resistant sensors

IO-Link interface included for free – Ideal for

Industry 4

Customer Solution

By mounting three separate M8- and C5-sized Contrinex

inductive sensors in a single fixture, all the demands of this

application can be met in full. Each sensor is chosen for its

combination of size, sensing distance and reliable detection of

one of the three different materials.

To detect the brass union nut, an M8-diameter sensor from

the Basic range (Extra Distance family) with a 4mm sensing

distance is an excellent choice. Fully embeddable with

chrome-plated nickel-silver bodies and PBTP sensing faces,

this sensor has a correction factor of 1.0 for brass,

outperforming competitors.

For detecting the steel spring, a 5mm-square-section sensor

from the Miniature range (Classics family) is an ideal option.

Embedding the sensor makes optimal use of its 1.5mm

sensing distance, and its chrome-plated brass body is well-

suited to the environment.

Each sensor is configured with an industry-standard PNP

normally-open interface and features a hermetically sealed

cable entry. All three are connected to the customer’s control

equipment via PUR-sheathed cables. Delivering the required

detection capabilities and sensing distances in small-bodied

sensors enables Contrinex to solve a previously insoluble

problem.

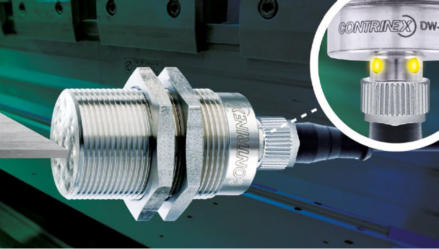

700 SERIES EXTREME ROBUST

STAINLESS-STEEL INDUCTIVE SENSORS -

‘HAMMER HOME’ AN ADVANTAGE

PRODUCT ADVANTAGES

WORLD CLASS PERFORMANCE IN EXTREME ENVIRONMENTS

CORROSION-RESISTANT, AISI 304 V2A STAINLESS-STEEL

BODY

EXTREMELY ROBUST ONE-PIECE, STAINLESS-STEEL HOUSING -

IMPACT AND ABRASION RESISTANT - IP68/ IP69K RATED

FACTOR 1 WITH BOTH FERROUS AND NON-FERROUS

MATERIALS INCLUDING ALUMINIUM & BRASS FOR EXTENDED

SENSING

CAN OPERATE IN CLOSE PROXIMITY WITHOUT INTERFERENCE

IO-LINK INTERFACE INCLUDED – IDEAL FOR INDUSTRY 4

Exceptional performance combined with unique robustness

make Contrinex’s Full stainless-steel EXTREME inductive

sensors the solution where reliability is valued. Thanks to their

housing being machined from a single piece of V2A/AISI 303

stainless-steel and a hermetically sealed cable entry, Extreme

sensors are corrosion-resistant, impervious to oil, and pressure-

resistant to 100 bar.

Rugged, reliable and highly accurate, the EXTREME range is at

home in the most challenging applications.

Developed to withstand the harshest industrial operating

conditions, Extreme sensors are rated to IP68 and IP69K,

delivering fit-and-forget performance with minimal downtime.

With operating distances up to 40 mm, the Extreme range

senses both ferrous and non-ferrous materials with Factor 1

performance, and is available in sizes from M8 to M30 and C23.

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS DEMONSTRATED

WATCH THE VIDEO TO SEE THE UNIQUE

ROBUSTNESS SURVIVE A HAMMERING

The sensor is configured with an industry-standard PNP

normally-open interface, and connection to the turbine’s

control systems is via an integral M12 connector and PUR-

sheathed cable. This allows easy removal and replacement

during routine maintenance. The sensor is corrosion-resistant

and impervious to water ingress. Reliability has been

excellent. Contrinex inductive sensors deliver a cost-effective

solution that satisfies the customer’s requirements for a

simple, fit-and-forget system.

CUSTOMER VALUES

Simple sensor system providing contactless

operation

Robust construction withstands corrosion and water

ingress

Exceptionally reliable, fit-and-forget operation in a

remote, harsh environment

PRODUCT ADVANTAGES

Extremely robust, impact and abrasion resistant

IP68/ IP69K rated housing.

Corrosion-resistant, one-piece AISI 304 (V2A)

stainless-steel body

State-of-the-art ASIC technology ensures

exceptional in-service reliability

10 mm sensing range available in physically small

sensor

Excellent resistance to extreme operating conditions

A single sensor is mounted in each turbine head, immediately

adjacent to the main mounting ring for the blade assembly.

As the blades rotate, so does the mounting ring, and the

sensor detects the presence of each mounting bolt as it

passes the sensing face. The angular spacing of the bolts is

known. Measuring the time that elapses between successive

signals thus allows the rotation velocity of the blades to be

calculated.

CUSTOMER SOLUTION

Rugged Full stainless-steel inductive sensors from the

Contrinex Extreme range are ideal for this application. Highly

reliable and rated to IP68 or IP69K, these units provide a cost-

effective alternative to tradition rotary-encoder technology.

A one-piece M18-diameter AISI 304 (V2A) stainless-steel body

and vacuum-encapsulated electronics make this device

particularly suitable for the hostile environment, and the

sensing distance of 10 mm allows fully contactless operation.

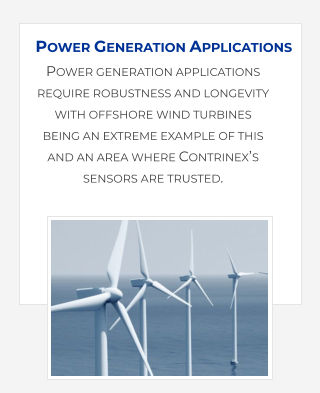

Modern wind turbines operate continuously in remote, highly

demanding environments. Exceptional reliability is essential as

opportunities for maintenance are limited. Turbine rotation

velocity is a key operating parameter and manufacturers

require robust sensor systems that provide accurate

measurement in real-time. Contrinex’s rugged inductive

sensors provide presence-sensing systems which withstand

harsh exposed conditions, both onshore and offshore, while

delivering the required accuracy and reliability.

CUSTOMER APPLICATION

A manufacturer of wind turbines provides engineering

support for systems installed around the globe. The company’s

field-service capability is backed by 24-hour remote data

monitoring, allowing early detection of potential problems.

Given the remote location of most wind farms, monitoring

systems must be exceptionally reliable, as site attendance is

infrequent.

Turbine rotation velocity is a key operating parameter, and the

company requires robust sensor systems that provide accurate

data in real-time. Traditional rotary-encoder technology is

unsuitable as sensors do not withstand prolonged exposure to

outdoor, often salt-laden, environments. In addition, turbine

rotation speeds are relatively low, typically requiring more

complex mechanical encoders.

The company requires a simple, contactless system that

provides fit-and-forget operation with extended maintenance

intervals. Sensors must be mechanically robust and must

withstand prolonged exposure to harsh outdoor conditions

including seawater. An industry-standard interface is highly

desirable to avoid the need for specialised control systems.

Rugged sensor construction ensures excellent resistance to

shock and vibration and a sensing distance of up to 10mm

eliminates any risk of accidental collision with moving parts.

These devices are corrosion-resistant and impervious to water

ingress, mud, ice and salt. Reliability has been excellent.

Contrinex inductive sensors deliver a cost-effective solution

that satisfies the customer’s requirements for a simple, fit-

and-forget system.

WELCOME TO PLUS AUTOMATION LTD - EXPERTS IN SENSORS,

WE WORK TO HELP YOU SOLVE YOUR APPLICATIONS, IMPROVE MACHINE

PERFORMANCE & RELIABILITY AND REDUCE COSTS USING CONTRINEX’S

EXCEPTIONAL SENSORS - LET US HELP YOU #MAKE SENSE OF SENSORS